Cylindrical member enclosure riveting mold

A riveting mold and cylinder technology, applied in the field of riveting molds, can solve the problems of inconvenient riveting of cylindrical parts, and achieve the effect of improving the qualified rate of riveting, convenient pick and place, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

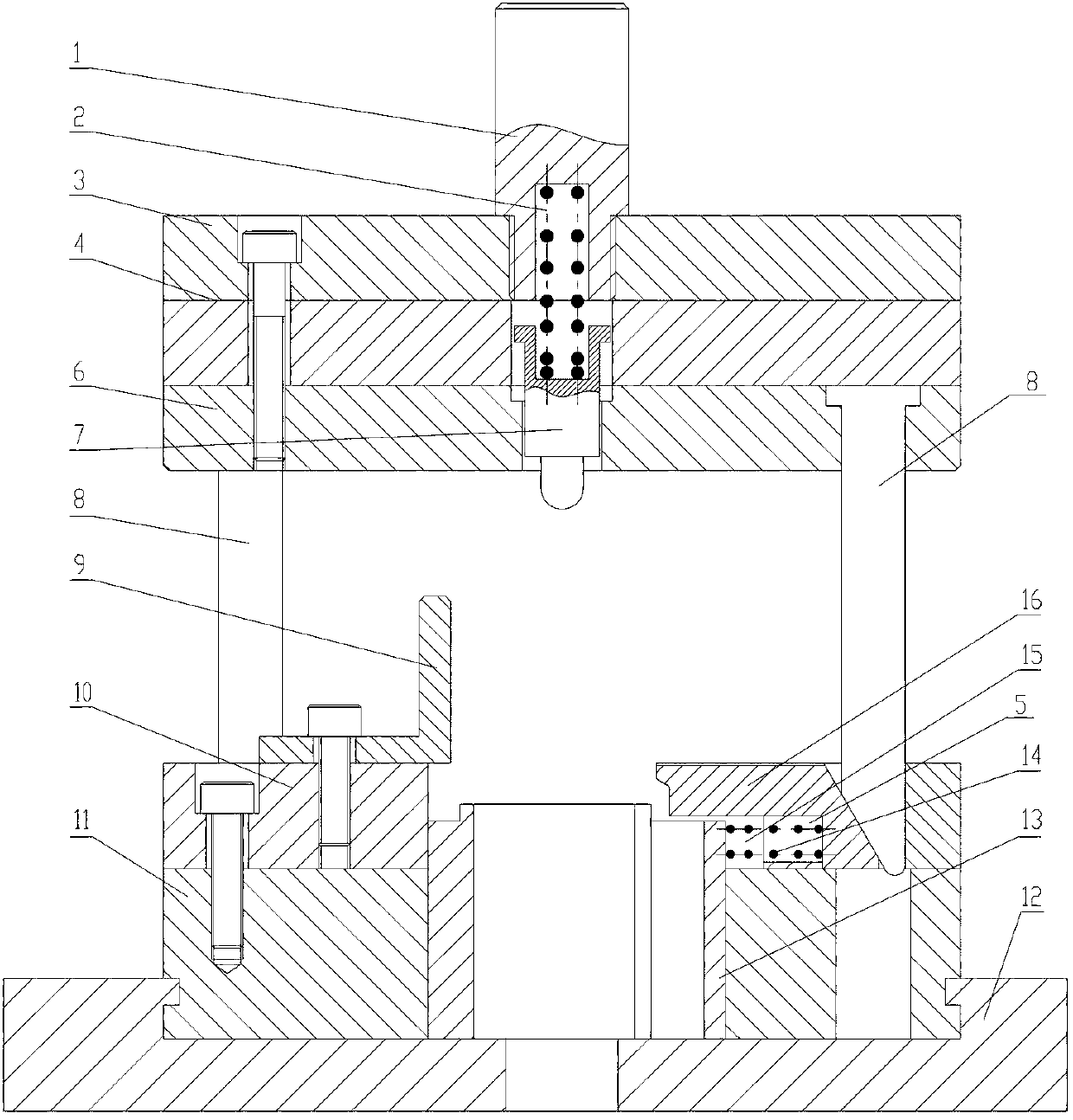

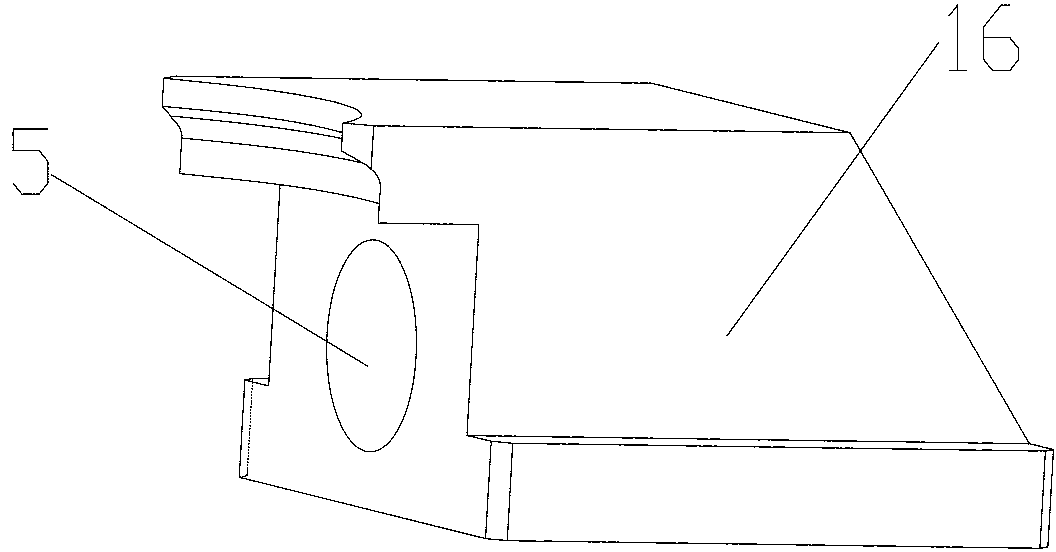

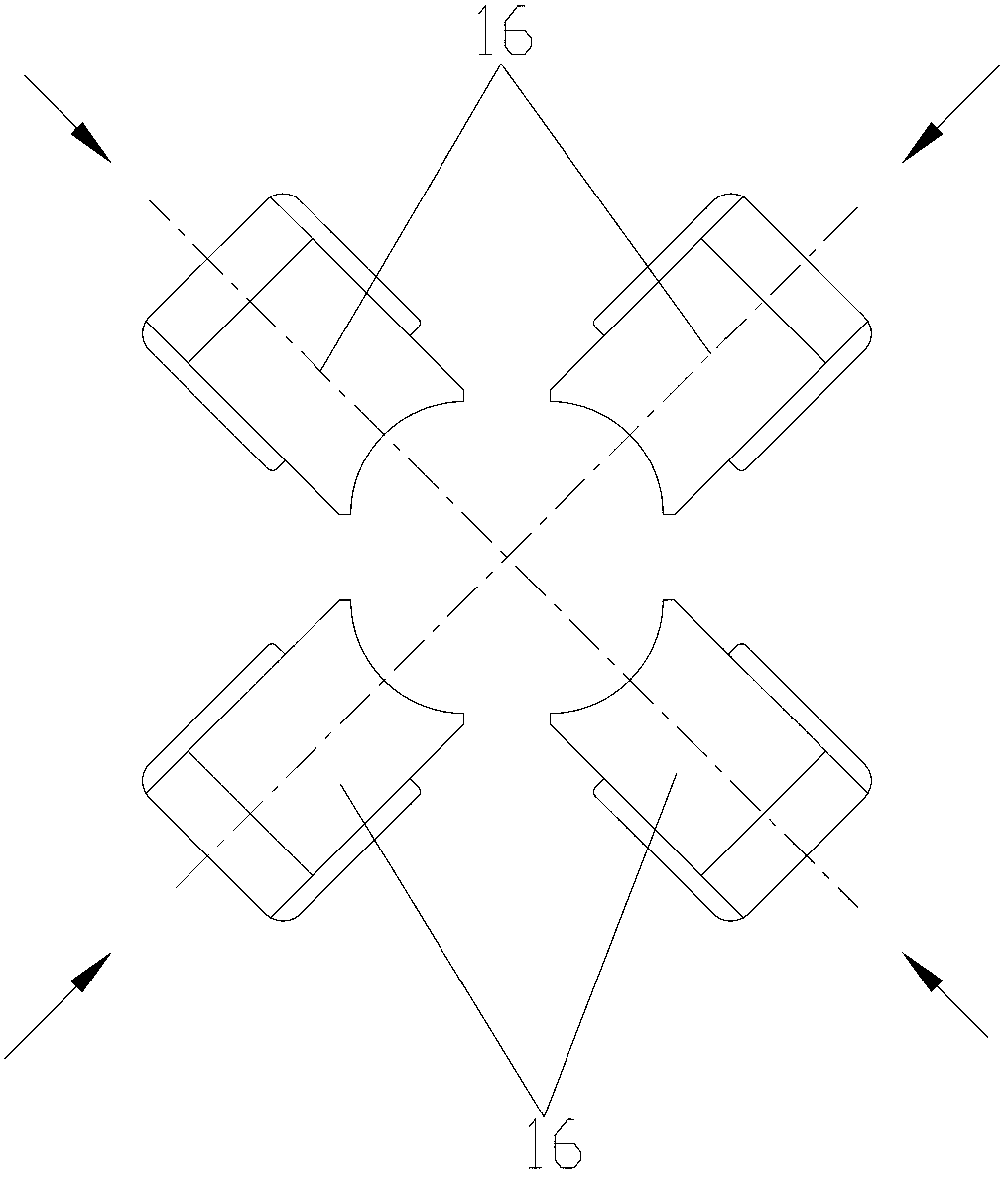

[0016] Examples such as Figures 1 to 4 As shown, a cylindrical part riveting mold includes an upper mold and a lower mold. The lower mold is provided with a bracket cover 13, and a group of riveting heads 16 of the riveting workpiece are arranged on the lower mold. The riveting head 16 is riveted The ends are closed to form a circle; the other end of the riveting head 16 is a slope structure, and the upper mold is provided with a group of slanting wedges 8 matched with the rivet 16, and the vertical movement of the slanting wedge 8 squeezes the rivet 16 to realize The lateral movement of the riveting head 16 causes the riveting head 16 to encircle the riveted workpiece in the middle. More specifically, there are four riveting heads 16 evenly arranged, and there are also four matching oblique wedges 8; the riveting head 16 A return stage clip 14 is also provided with the lower die. Described lower die comprises bottom plate 12, the supporting plate 11 that is fixed on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com