Hard alloy hole boring cutter

A technology of cemented carbide and boring tool, which is used in the accessories of tool holders, metal processing equipment, tools for lathes, etc., can solve the problems of waste, high tool manufacturing cost, low cutting speed, etc., and reduce production costs. , Improve production efficiency, good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

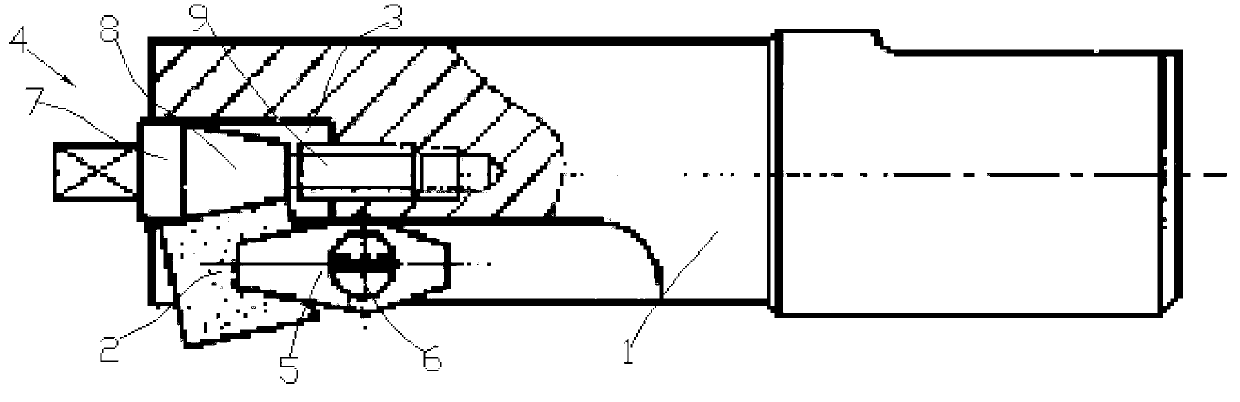

[0011] attached figure 1 It is a cemented carbide boring tool according to the present invention. It is mainly composed of a cutter body 1, a blade 2, a pressure screw 4, a positioning screw 6, and a pressure plate 5. A cylindrical hole 3 is provided on one end of the cutter body 1. , the pressure knife screw 4 is composed of a cylindrical section 7, a tapered section 8 and a threaded screw section 9; the screw section 8 of the pressure knife screw 4 is connected to the cutter body 1 through the cylindrical hole 3; the Said blade 2 is installed close to the tapered section 8 of the pressure knife screw 4; when the pressure knife screw 4 is screwed in, the blade 2 close to the tapered section 8 expands outward; the positioning screw 6 is tightened by the pressure plate 5 to fasten the blade 1.

[0012] The above-mentioned embodiments are only to illustrate the technical conception and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com