Blade grinding clamp of silicon steel sheet punching die punch

A technology of punching die and silicon steel sheet, which is applied in the field of tooling and fixtures, can solve the problems of reducing the service life of punches, poor angle and alignment, and inconvenient adjustment of angles, so as to improve clamping efficiency, increase service life, and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

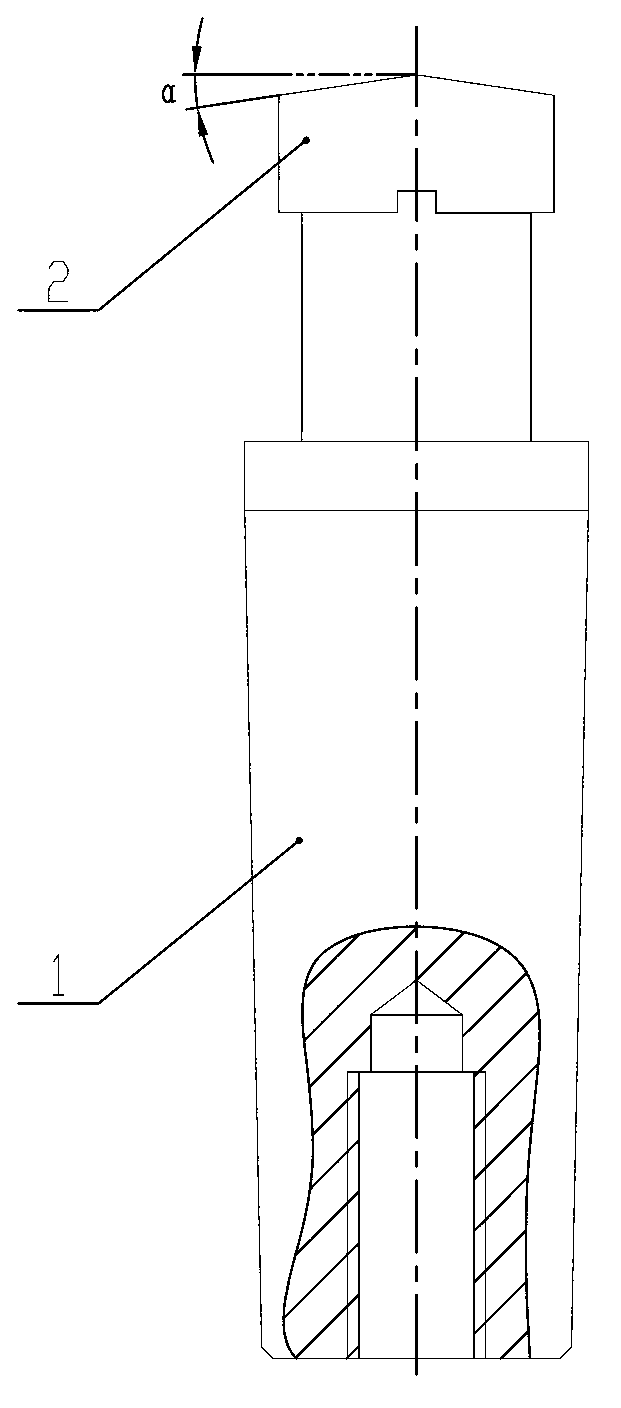

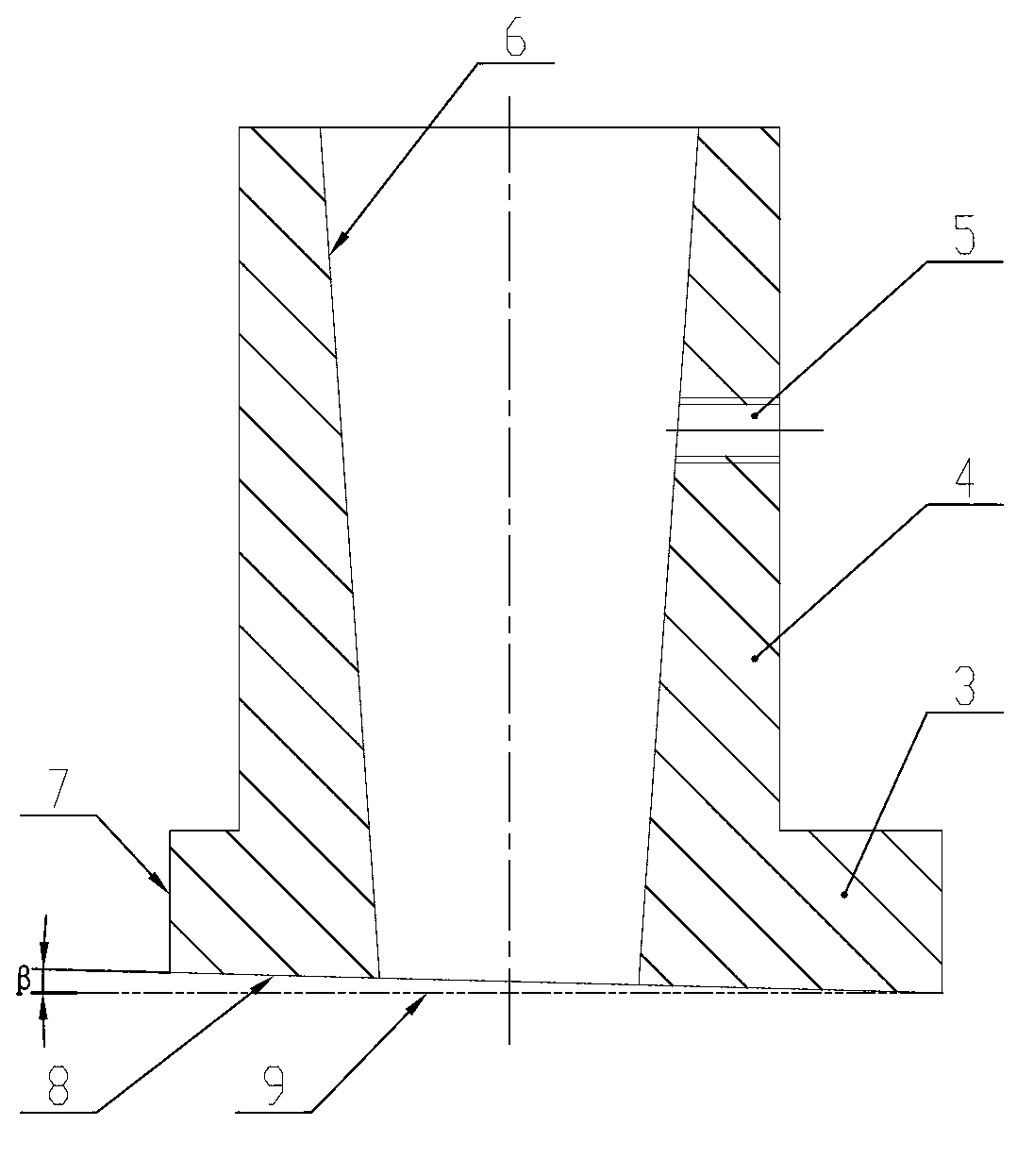

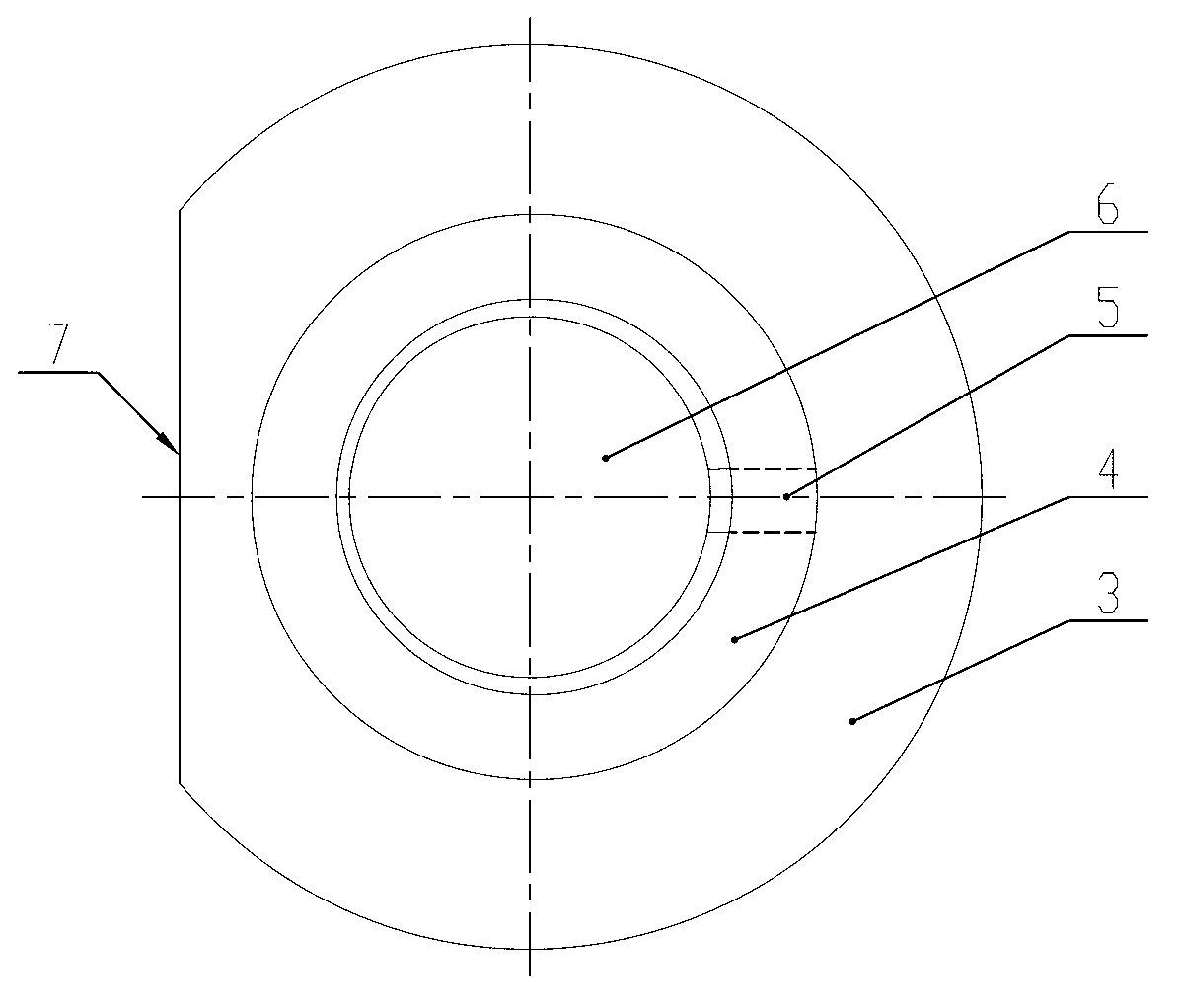

[0018] Figure 1 ~ Figure 3 Among them, including mold rod 1, punch 2, flange plate 3, clamp body 4, jacking screw 5, mold rod loading hole 6, centering plane 7, bottom surface 8, plane 9, etc.

[0019] like figure 1 Shown is a punch of a silicon steel sheet punching die, the punch 2 is fixed on the end of the die rod 1, and the die rod 1 is generally tapered. The end face of the punch 2 is a knife-edge shape formed by two symmetrical slopes, each slope forms a first angle α with a plane perpendicular to the axis of the die bar 1 . The first included angle α is generally 1.5°˜3°.

[0020] like figure 2 , image 3 As shown, it is a sharpening fixture for a silicon steel sheet punching die punch. The clamp includes an upright cylindrical clamp body 4, which is generally cylindrical. A mold rod loading hole 6 matching the mold rod 1 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap