Parallel mechanism containing prr open-loop sub-chain and pprpr closed-loop sub-chain

A closed-loop sub-chain and sub-chain technology, applied in the field of robotics, can solve the problem that multiple drives cannot be connected to the frame at the same time, and achieve the effect of small inertia of the mechanism and good dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

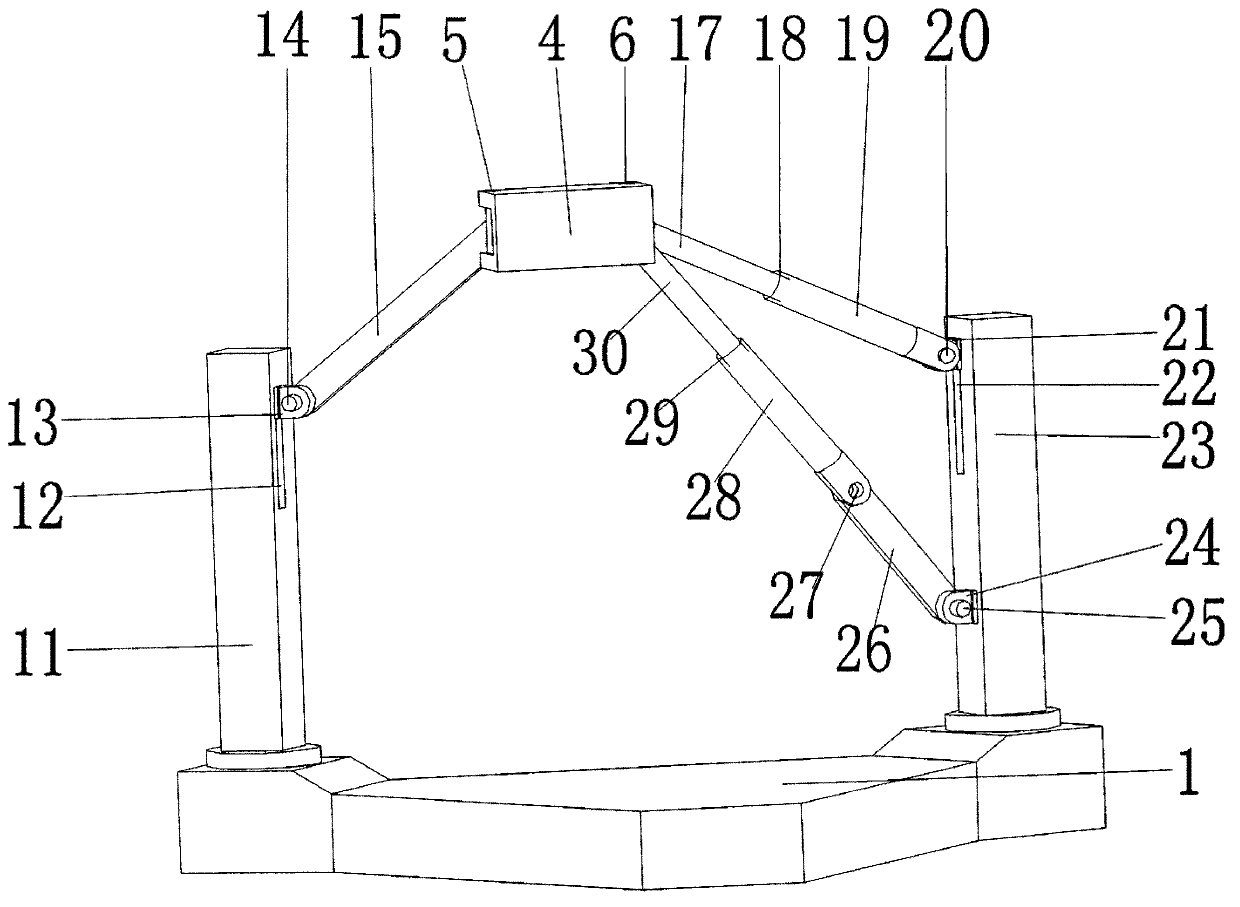

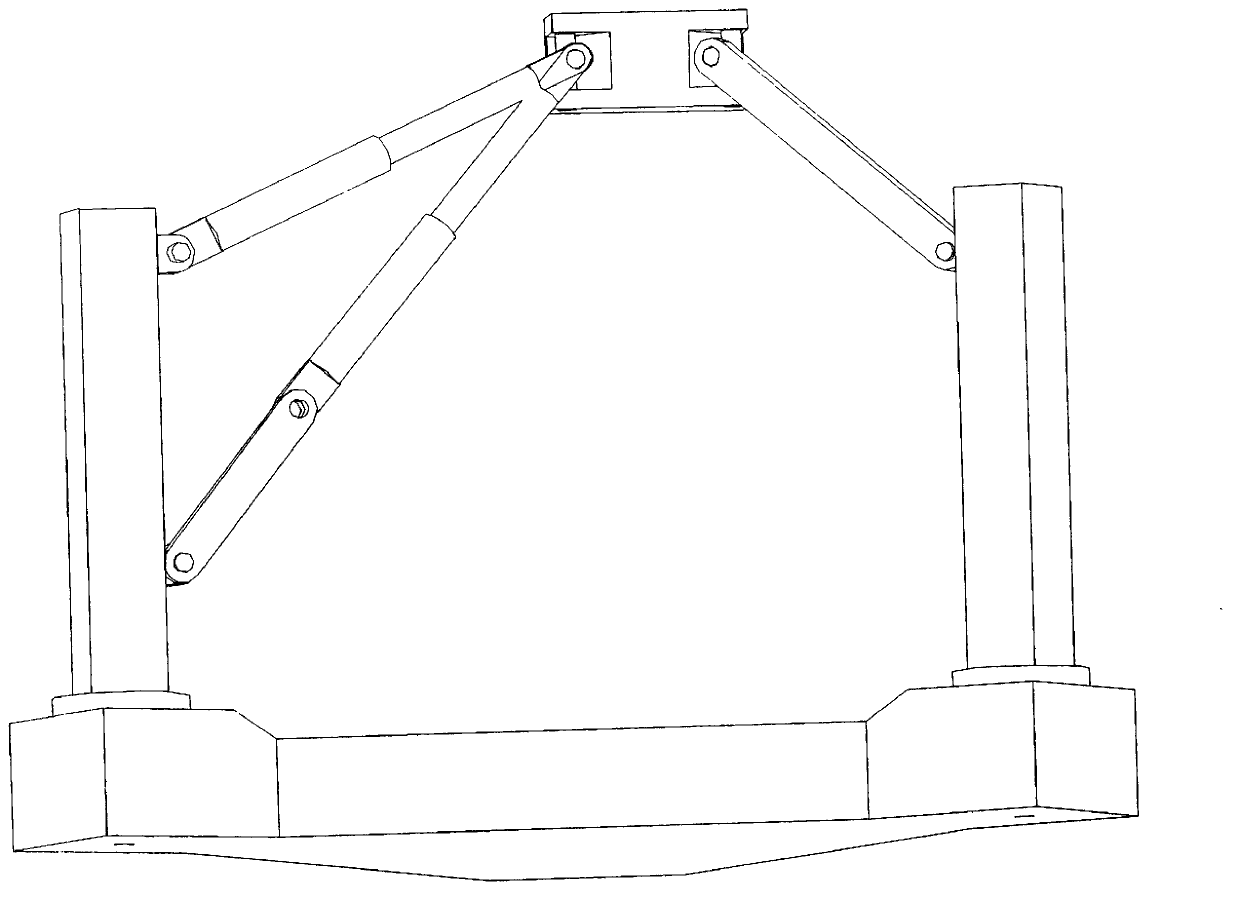

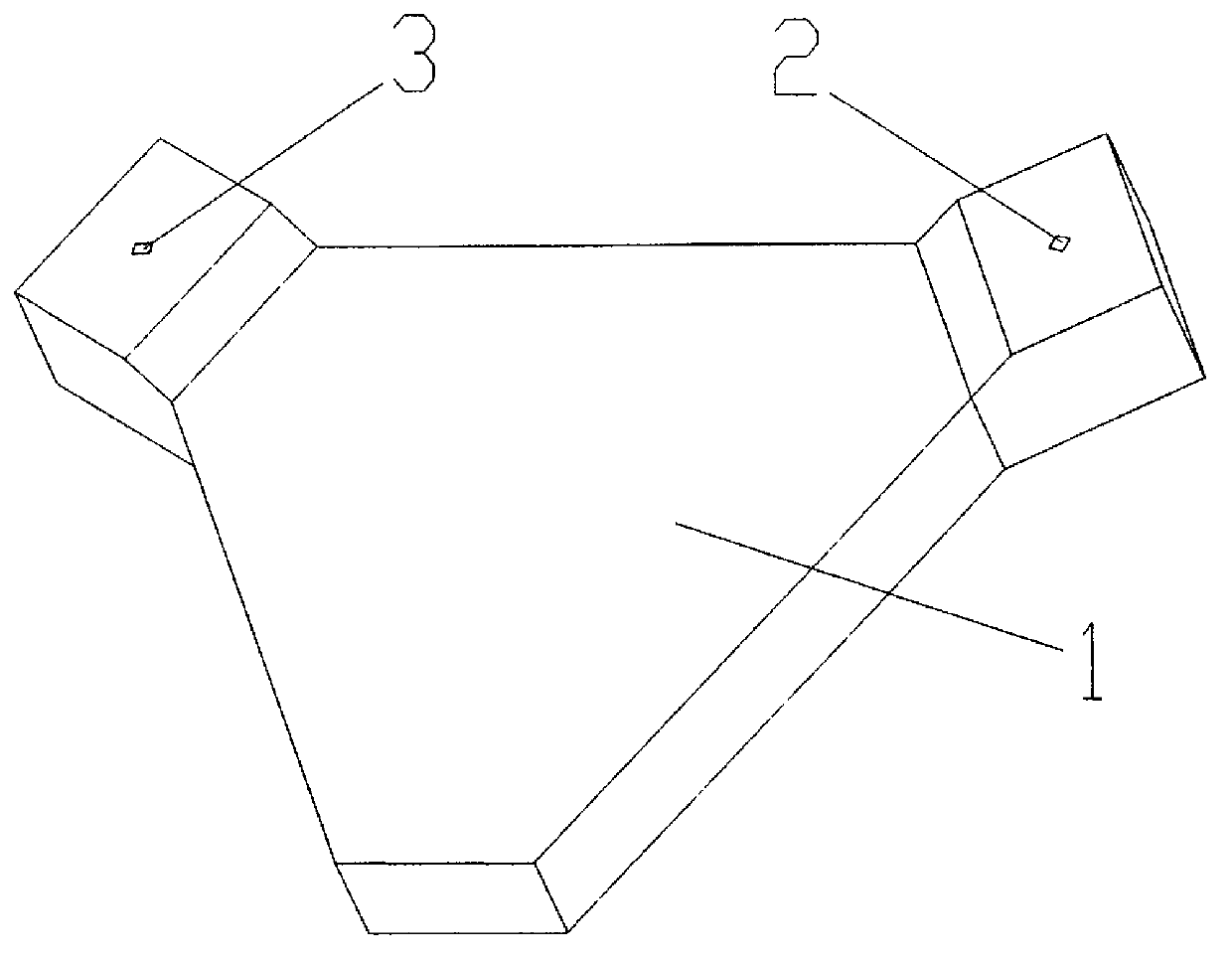

[0019] control figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 , a five-degree-of-freedom parallel mechanism with a closed-loop sub-chain, including an actuator sub-chain and a six-bar mechanism closed-loop sub-chain, its structure and connection method are:

[0020] The sub-chain of the actuator is formed by connecting the first connecting rod 11, the second connecting rod 15, the first slider 13, the first Hooke hinge 7, the moving platform 4 and the frame 1, and one end of the first connecting rod 11 passes through The first rotating pair 2 is connected on the frame 1, the other end of the first connecting rod 11 is connected with the first sliding block 13 through the first moving pair 12, and the other end of the first sliding block 13 is connected with the second connecting rod through the second rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com