Compound coiled material and preparation method thereof

A technology of composite rolls and waterproof rolls, which is applied in the direction of chemical instruments and methods, building insulation materials, synthetic resin layered products, etc., can solve the problems of surface layer hollowing, falling off, endangering the enclosure structure and personnel safety, etc., to achieve The effect of simple processing technology and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

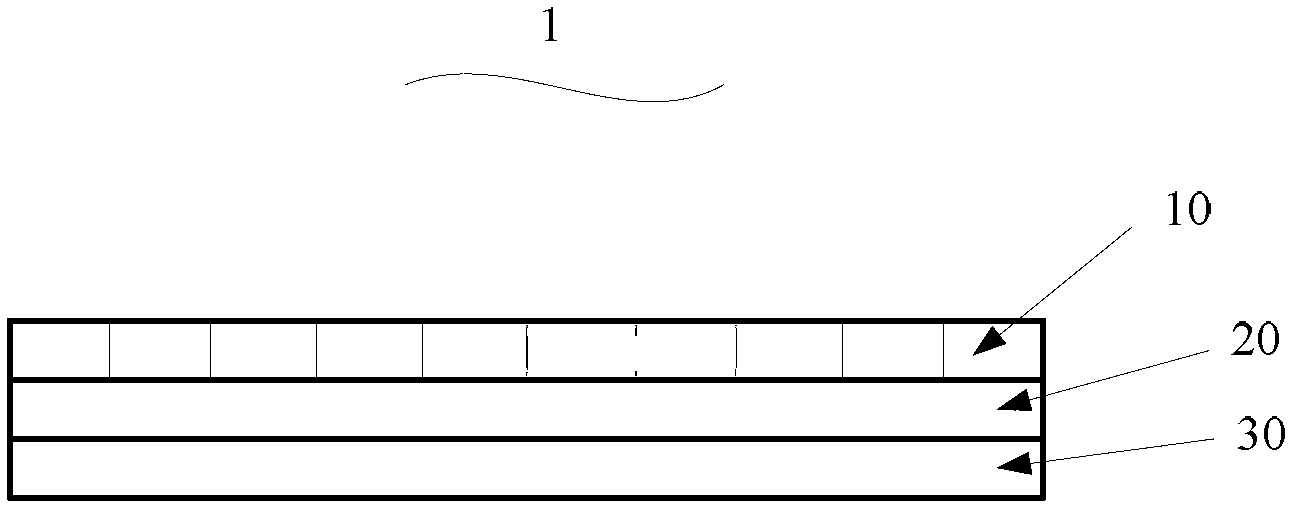

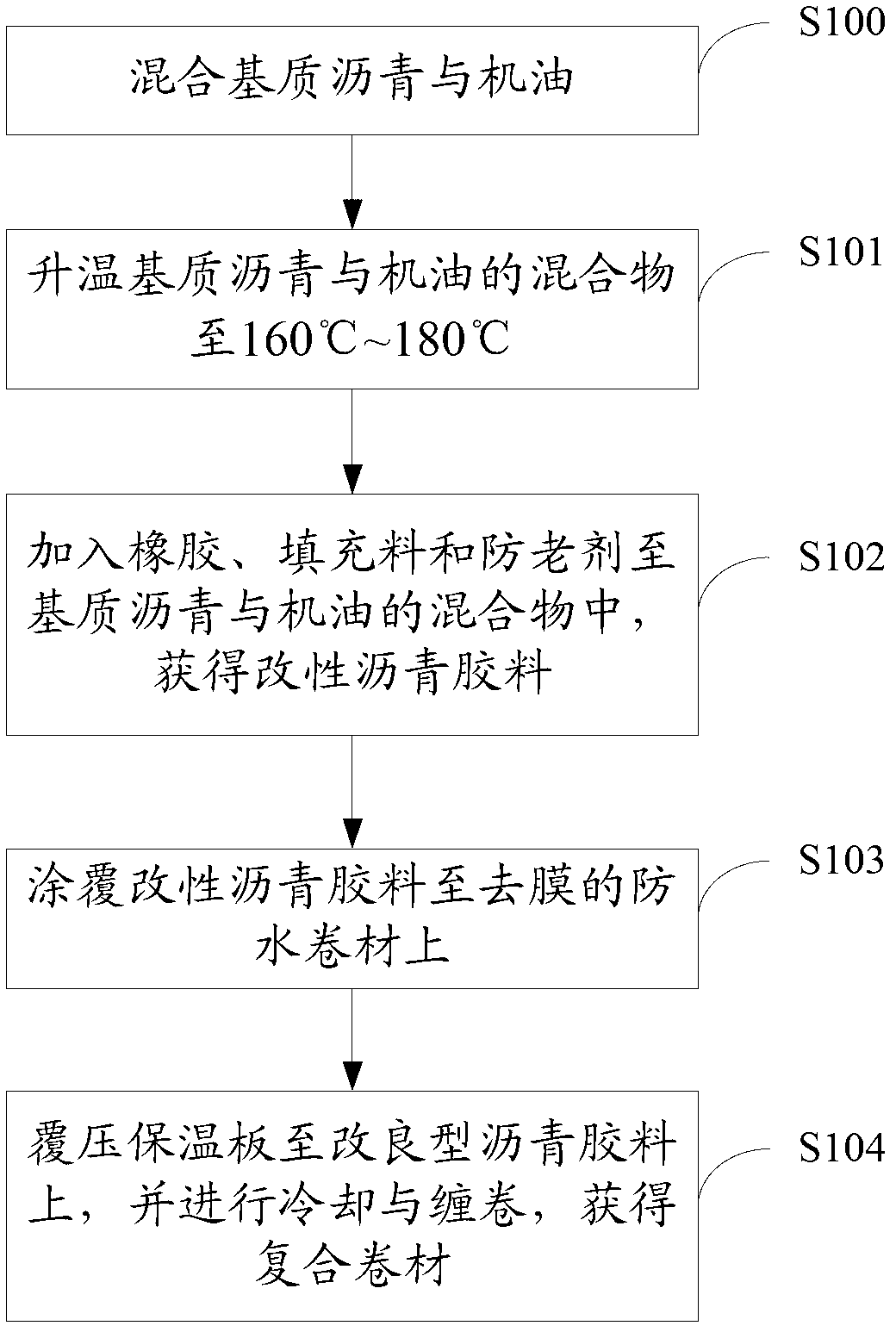

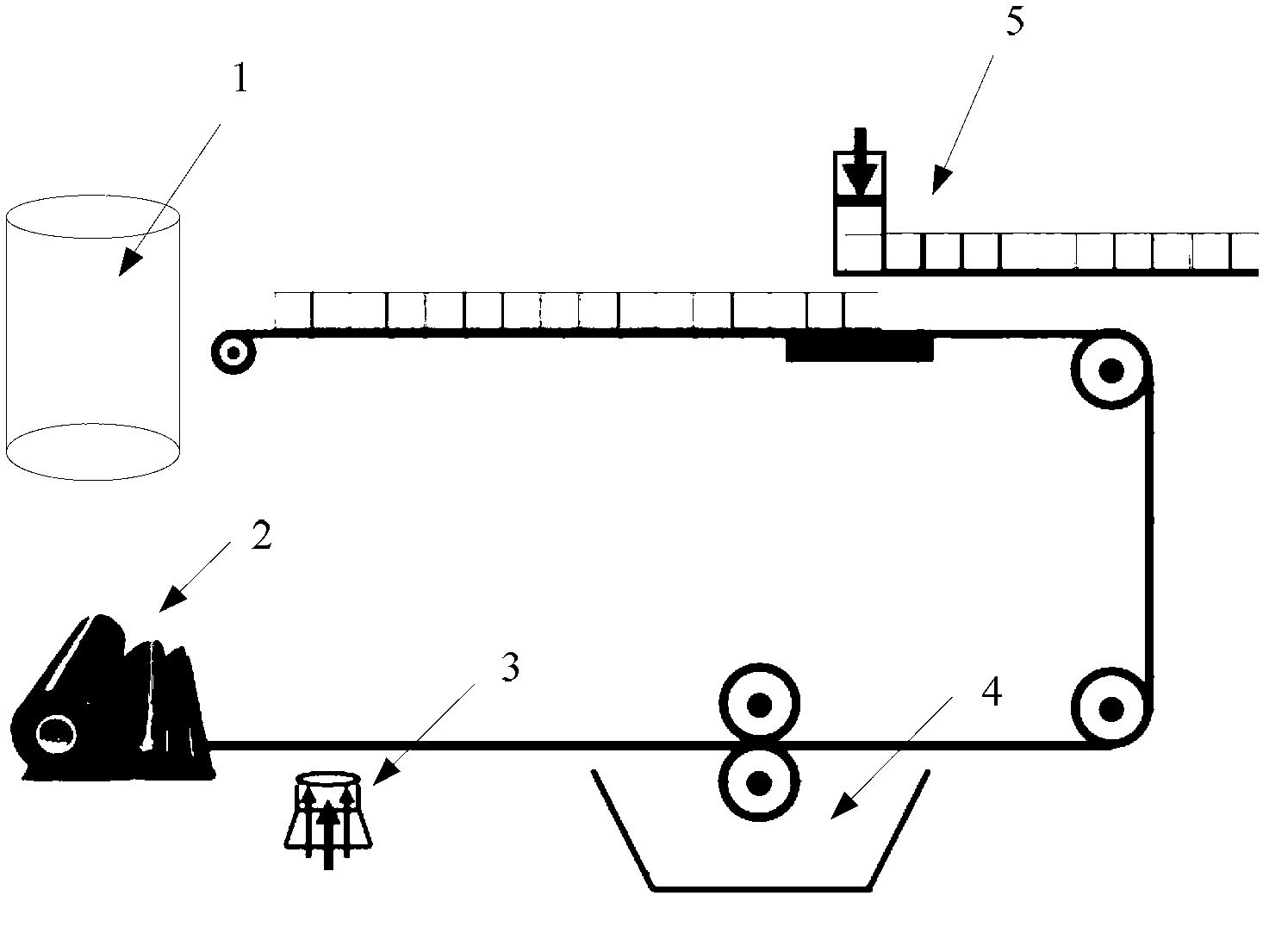

[0025] Such as figure 2 Shown is a flow chart of the preparation method of the composite coil 1. The following is combined according to the flowchart image 3 Describe the preparation method of composite coil 1, wherein image 3 It is a schematic diagram of the process of the preparation method of the composite coil 1.

[0026] Step S100, mixing base asphalt and engine oil.

[0027] Step S101, heating the mixture of base asphalt and engine oil to 160°C-180°C.

[0028] Step S102, adding rubber, fillers and antioxidants to the mixture of base asphalt and engine oil to obtain modified asphalt 20 sizing material. Specifically: heating up the mixture of base asphalt and engine oil with rubber, filler and antioxidant to 180℃-200℃, after stirring for 1-2 hours, control the material temperature to 170℃-190℃ to obtain modified asphalt 20 compound , And put the modified asphalt 20 rubber material in the dip tank 4.

[0029] In step S103, the coating device 4 coats the modified asphalt 20 s...

Embodiment 1

[0032] A common waterproof coiled material 2 / polystyrene foam insulation board 10 composite coil 1 and its production process, the preparation process is as follows:

[0033] The ordinary waterproofing membrane 2 is put on the shelf to unfold and bake to remove the film-coated with modified bitumen 20 rubber-laminated polystyrene foam insulation board 10-cooling-winding-the finished product process to obtain a combination of waterproof and thermal insulation functions Of multifunctional composite coils1. Among them, the modified asphalt 20 rubber composition includes 12% engine oil, 5% SBS (styrene-butadiene-styrene, styrene-butadiene-styrene block polymer elastomer), 35% filler, 7% anti-aging The rest is base asphalt. The thickness of the modified asphalt 20 coating material is 2mm. The width of the overlapping edge of the multifunctional composite coil 1 is 8 cm. The length of the polystyrene foam insulation board 10 is 90 cm, and the width and thickness are both 5 cm. Afte...

Embodiment 2

[0035] A self-adhesive waterproof coiled material 2 / polyurethane insulation board 10 composite coil 1 and its production process, the preparation process is as follows:

[0036] The self-adhesive waterproofing membrane 2 is put on the shelf to remove the film-coated with modified asphalt 20 rubber-laminated polyurethane insulation board 10-cooling-winding-the finished product process flow to obtain a multifunctional composite that integrates waterproof and thermal insulation functions Coil 1, see the schematic diagram of the process flow figure 2 . Among them, the modified asphalt 20 rubber composition includes 15% engine oil, 5% SBS, 40% filler, 8% antioxidant, and the rest is base asphalt. The thickness of the modified asphalt 20 coating material is 3mm. The width of the overlapping edge of the multifunctional composite coil 1 is 10 cm. The length of the polyurethane insulation board 10 is 90 cm, and the width and thickness are both 4 mm. After coating the modified asphalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com