Actuator and method for manufacturing the same

A manufacturing method and actuator technology, which are applied in the manufacture of printed circuits, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as the inability to obtain high-speed responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

[0040] First, the first embodiment of the actuator of the present invention will be described.

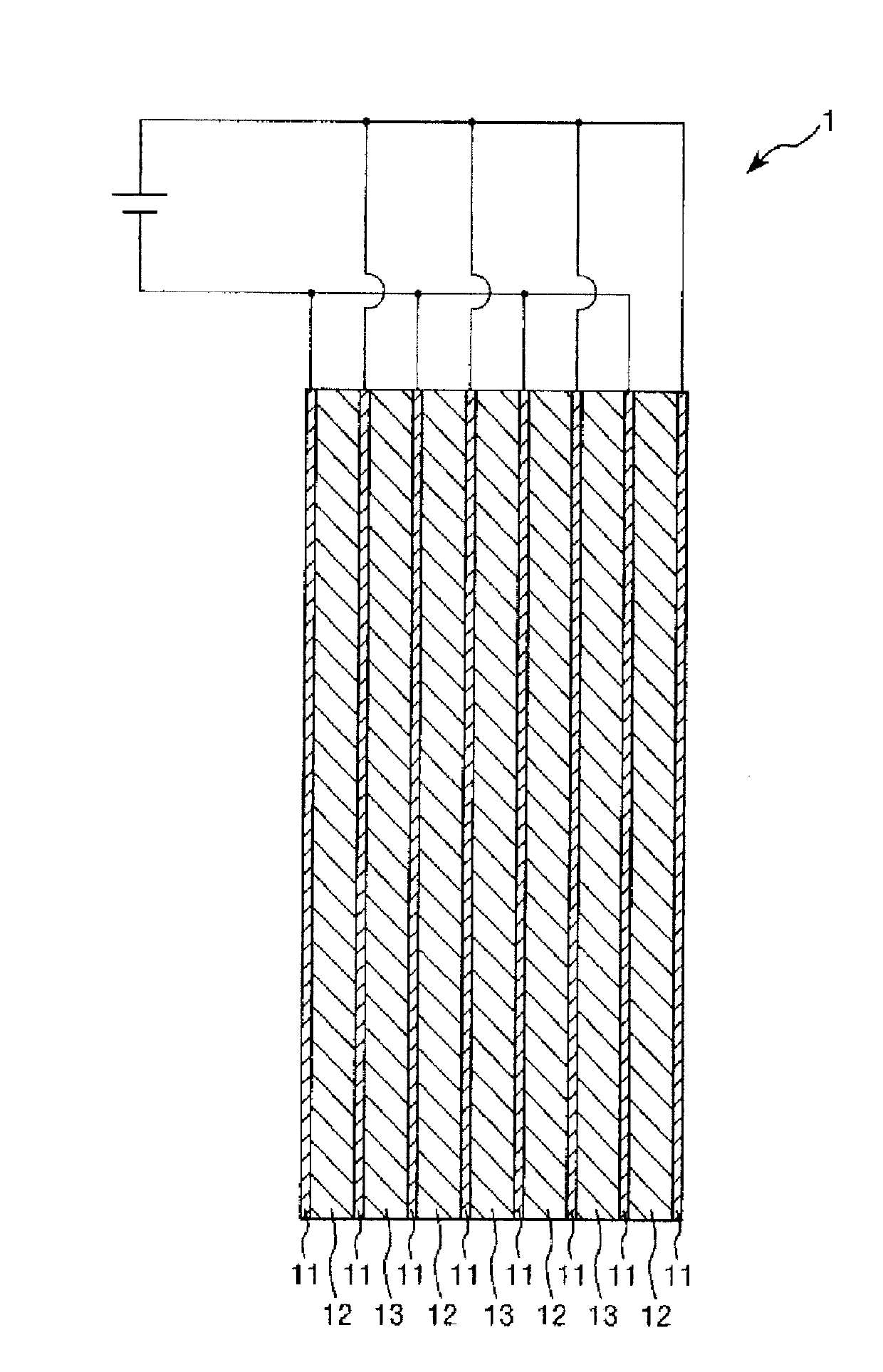

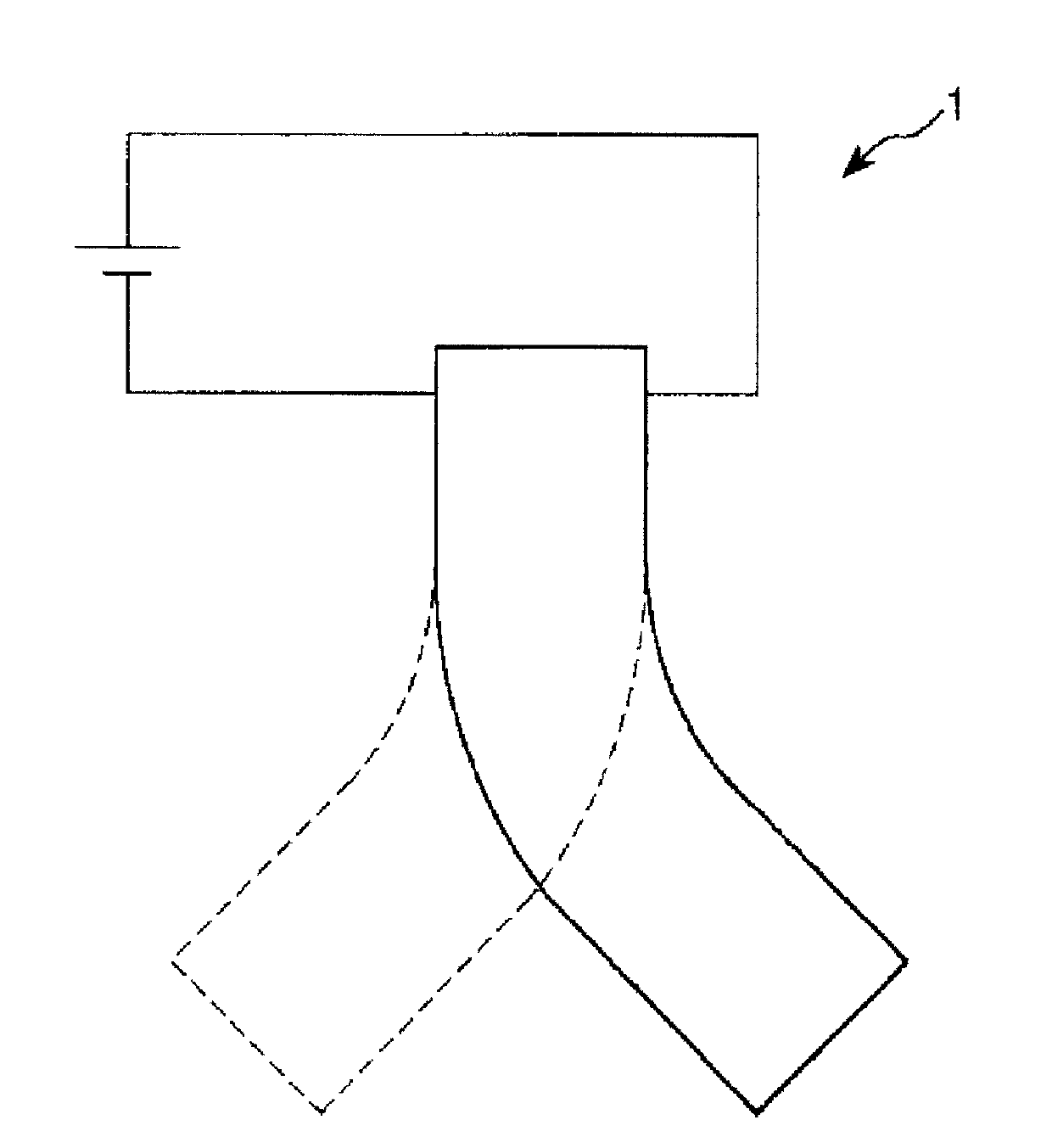

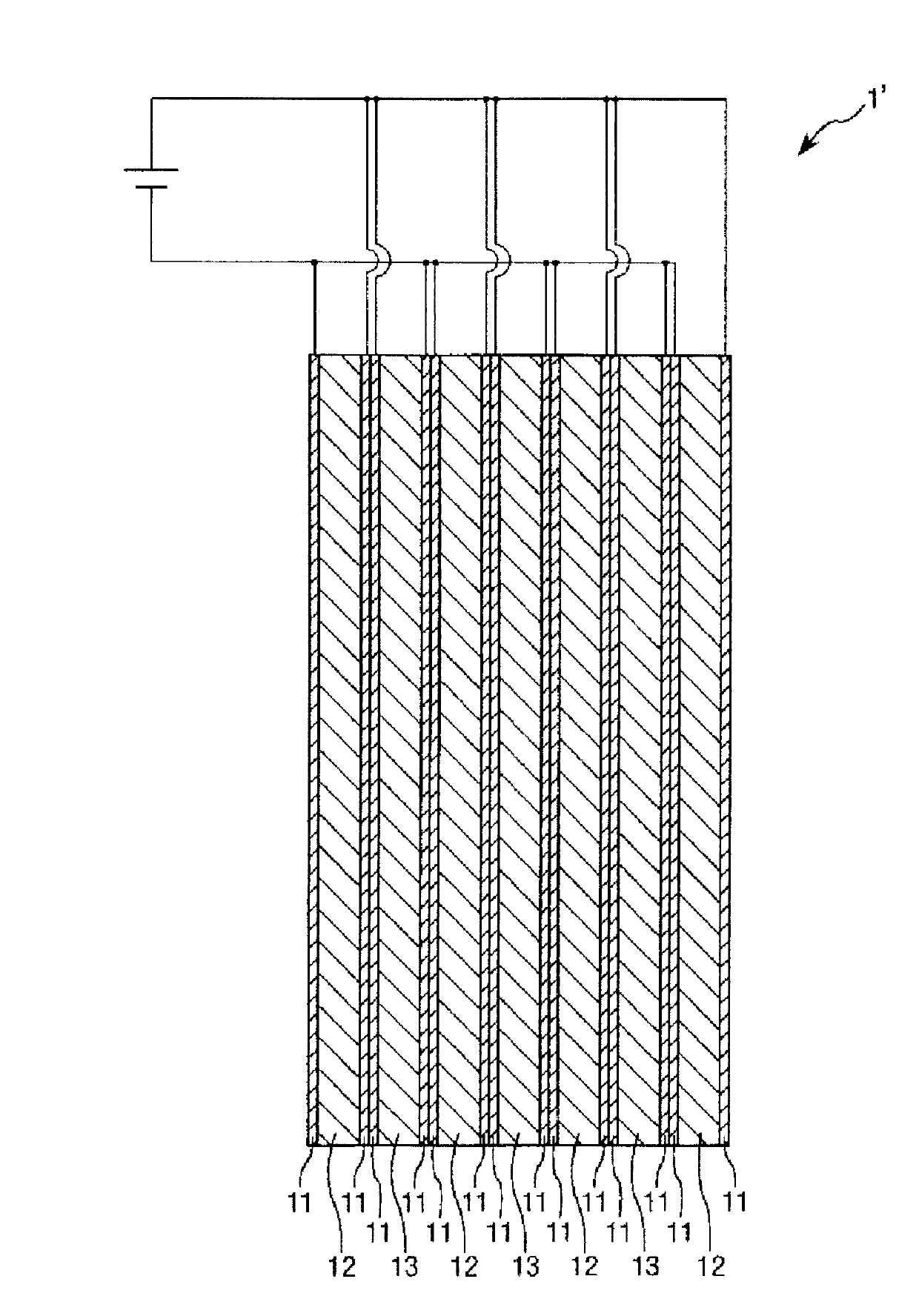

[0041] figure 1 is a cross-sectional view showing a first embodiment of the actuator of the present invention, figure 2 It is a schematic diagram which shows the drive state of the actuator of 1st Embodiment.

[0042] The actuator 1 is composed of a laminate in which a plurality of electrodes 11 , a plurality of cation exchange resin membranes 12 , and a plurality of anion exchange resin membranes 13 are stacked. In this embodiment, as figure 1 As shown, it consists of four cation exchange resin membranes 12 , three anion exchange resin membranes 13 , and eight electrodes 11 .

[0043] like figure 1 As shown, the actuator 1 is alternately laminated with cation exchange resin membranes 12 and anion exchange resin membranes 13 .

[0044] Furthermore, one electrode 11 is arranged between the cation exchange resin membrane 12 and the anion exchange resin membrane 13 .

[0045] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com