Powdery accelerator for calcium-containing aluminosilicate cementing material

A gelling material and aluminosilicate technology, applied in the field of powder accelerators, can solve the problems of large strength loss, uneven dispersion, and large amount of dust in the later stage, and achieve good workability, good adaptability, and rebound small effect

Inactive Publication Date: 2013-03-27

CHINA RAILWAY TUNNEL GROUP CO LTD

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantages of powder accelerators are uneven dispersion in concrete, large amount of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

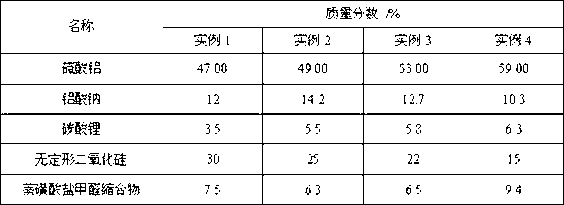

The invention discloses a powdery accelerator for a calcium-containing aluminosilicate cementing material, composed of aluminum sulfate, sodium aluminate, lithium carbonate, amorphous silica and formaldehyde naphthalene sulfonate condensate, wherein the aluminum sulfate accounts for 45-65%, while the sodium aluminate accounts for 10-15%, lithium carbonate accounts for 3-7%, the amorphous silica accounts for 15-30% and the formaldehyde naphthalene sulfonate condensate accounts for 5-10%. Compared with the traditional powdery accelerator, the powdery accelerator provided by the invention has the advantage that the newly stirred slurry is high in viscosity, good in workability, low in disability in the spraying construction process, and good in adaptability to the cementing material with the compound accelerating mechanism.

Description

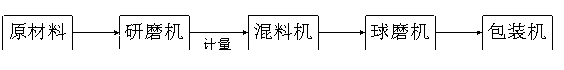

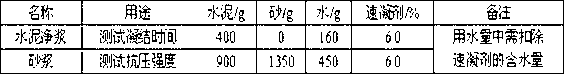

technical field [0001] The invention relates to a technology of aluminosilicate gelling materials, in particular to a powder accelerator for calcium-containing aluminosilicate gelling materials. Background technique [0002] The quick-setting agent is added in the concrete preparation process to make the concrete set and harden quickly after construction, which is indispensable for the construction of rapid traffic roads, mining, tunnel construction, water conservancy and hydropower projects, and rapid repair of buildings. [0003] The effect of the accelerator in concrete depends on the chemical composition and dosage of the accelerator, the mineral composition and content of cement, the type and content of gypsum, the type and amount of mineral admixtures, and the temperature during construction, etc. factors. The accelerating mechanism of accelerators on cement usually includes the following three types: (1) hydration products are formed through the reaction of their own...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/22C04B103/12

Inventor 韩建国史继尧王玥

Owner CHINA RAILWAY TUNNEL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com