Pillar foundation for crossing for contact screen of hanging basket

A catenary and pillar technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems affecting the overall performance of reinforced concrete structures, insufficient stability of hanging baskets, and complicated treatment of stubble surfaces, so as to ensure project quality and construction period , low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

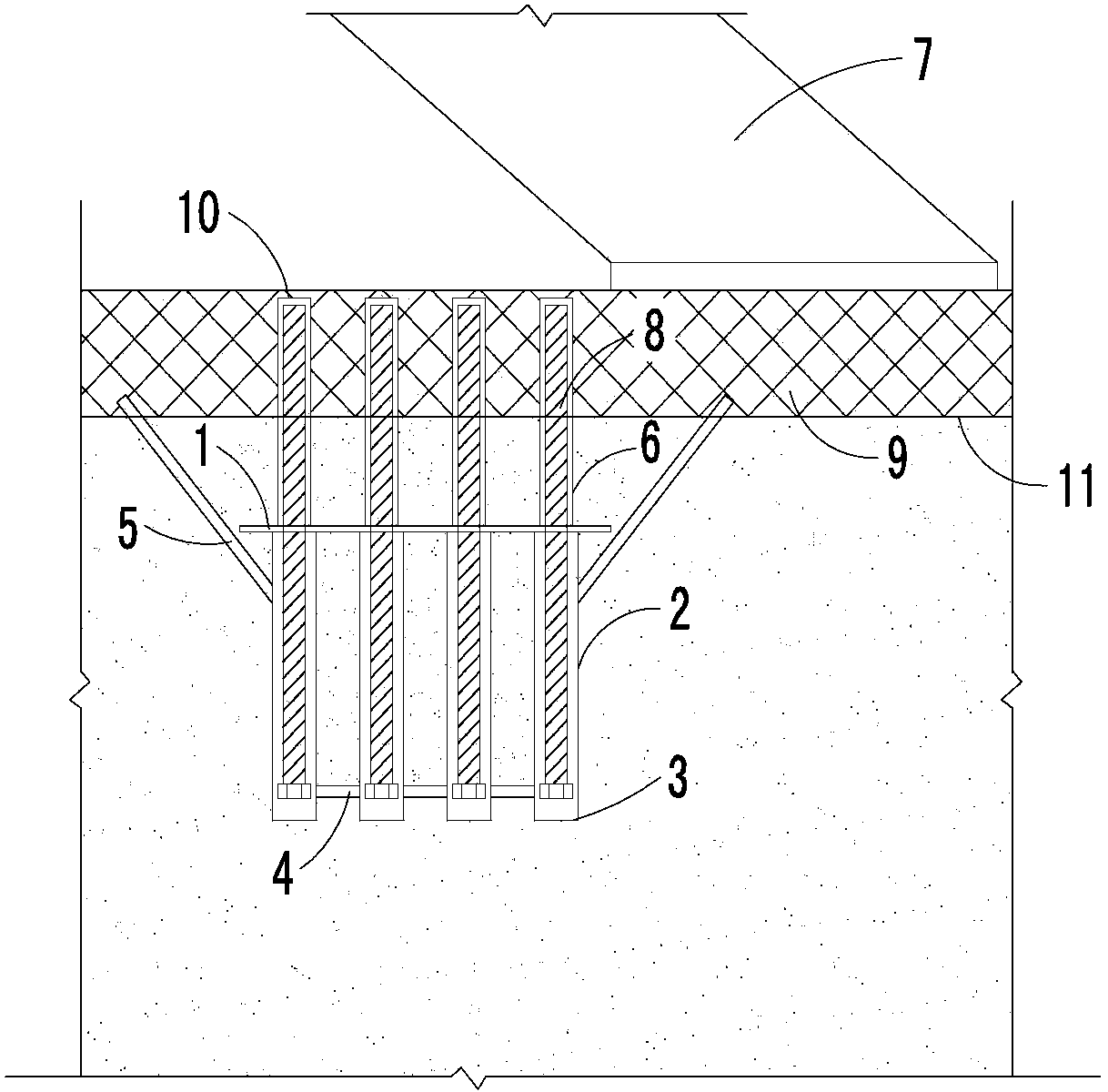

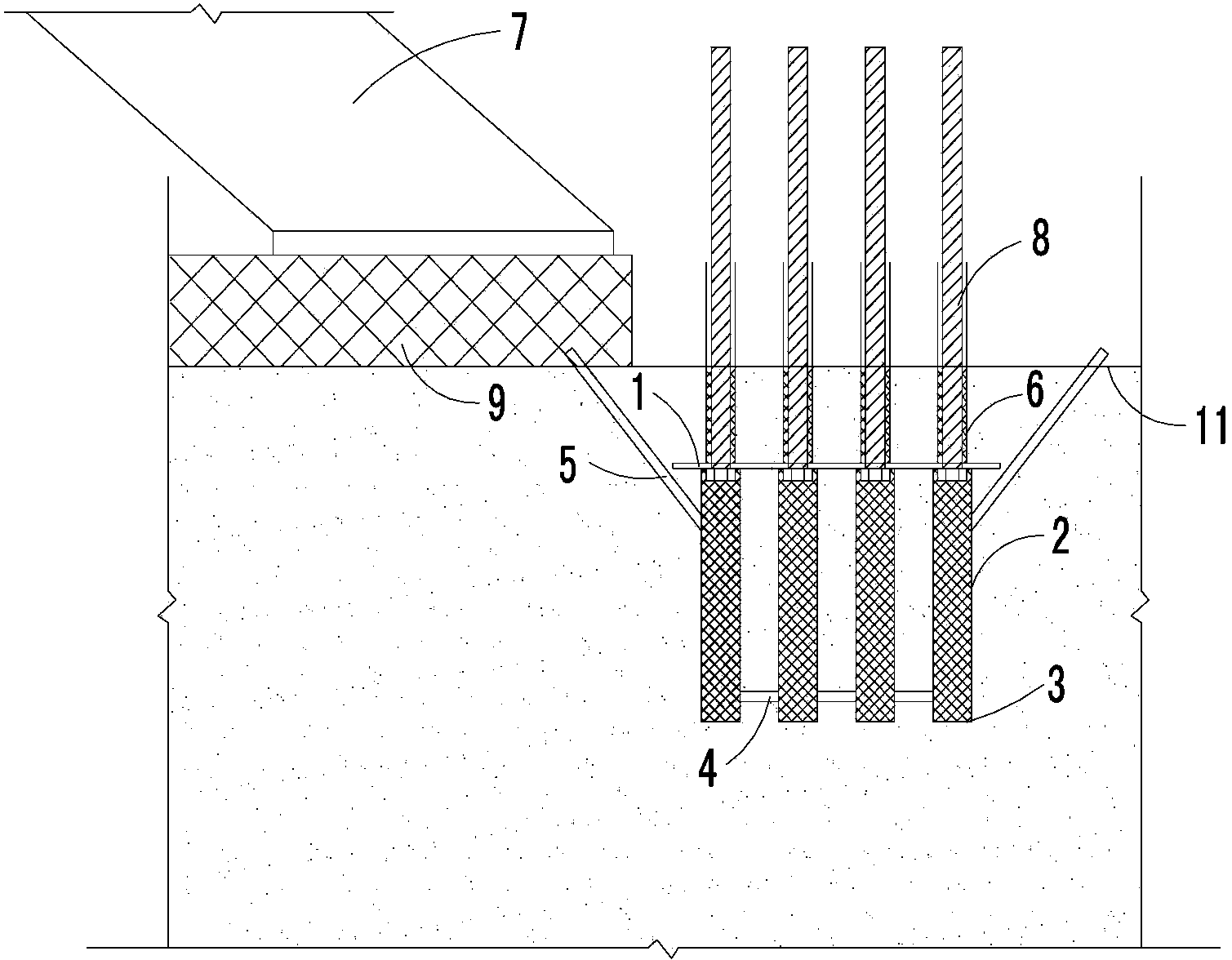

[0017] see figure 1 and figure 2 In this embodiment, the catenary pillar foundation of the hanging basket is to weld the lower casing 2 at the bottom of the embedded steel plate 1 of the catenary pillar foundation, and weld the bottom plate 3 at the bottom of the lower casing 2 so that the bottom end of the lower casing 2 is closed. The adjacent lower casings 2 are connected with the horizontal pipe 4 at the bottom of the lower casing 2, and the grouting pipe 5 is welded on the upper part of the lower casing 2 and led to the concrete top surface 11; the upper part of the embedded steel plate 1 Weld the upper casing 6 and cap it with the upper cover 10; the upper casing 6 and the lower casing 2 are vertically penetrated through the embedded steel plate 1; the anchor bolt 8 is placed in the casing formed by the penetration of the upper casing 6 and the lower casing 2 and can move up and down in the casing.

[0018] In specific implementation, the depth of the lower casing 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com