Internal-concentrator honeycomb sandwich plate type solar collector

An inner concentrating, flat-plate technology, applied in the direction of solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of the intensity and time limit of sunlight, and affect the use of low-level families, and achieve low cost, novel concept, technologically advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

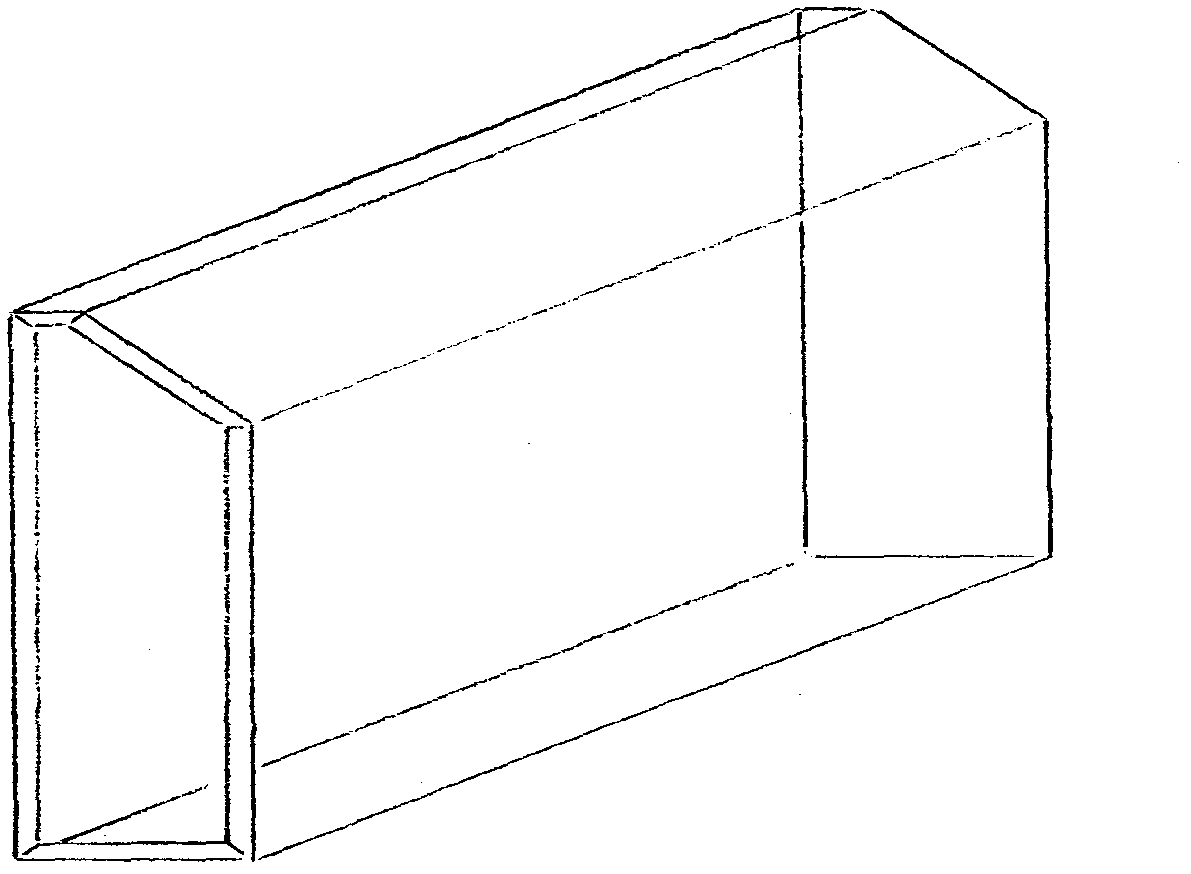

[0009] 1. Make the frame as shown in the picture with aluminum profile. Seal the left, right and lower sides of the frame for heat preservation

[0010] 2. Place the insulation board on the bottom of the frame.

[0011] 3. According to the design requirements, unfold and reshape the lower aluminum honeycomb sandwich and combine it with the aluminum bottom plate, and remove the dust on the surface to keep it clean. This combination is called inner concentrating honeycomb sandwich. Place on insulation board.

[0012] 4. Weld the medium pipe according to the design requirements, and spray the absorbing film layer.

[0013] 5. According to the size of the medium pipe, the upper aluminum honeycomb sandwich is processed into a number of holes, and after unfolding and shaping, the absorbing film layer is sprayed.

[0014] 6. Insert the medium tube into the hole groove of the upper honeycomb sandwich to form a honeycomb sandwich finned tube heat collector, and then install it on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com