Weighing and hanging device of cement packing machine

A technology of suspension device and packaging machine, which is applied in the direction of measuring device, weighing, detailed information of weighing equipment, etc., can solve the problems of large influence on installation and maintenance accuracy, increased instability of weighing frame, large weighing error, etc. , to achieve the effect of reducing maintenance workload, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

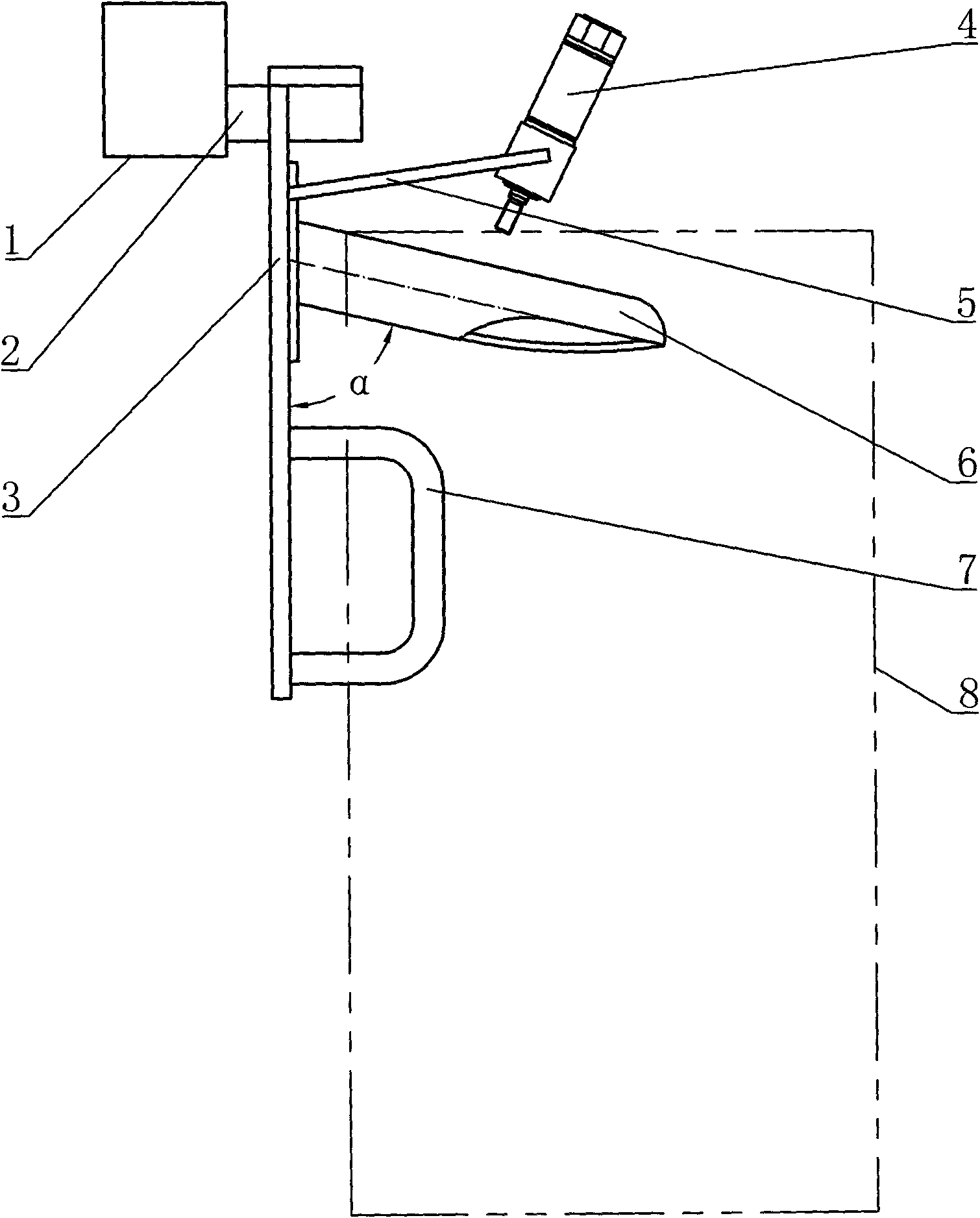

[0007] figure 1 Shown in is a specific embodiment of the present invention, the cement packaging machine weighing suspension device of the present invention comprises fixed support 1, sensor 2, scale frame baffle 3, bag presser 4, connecting plate 5, discharge nozzle 6 And control rod 7, one end of sensor 2 is fixedly connected with fixed support 1, and the other end is rigidly connected with scale frame baffle plate 3, and bag presser 4 is connected with scale frame baffle plate 3 through connecting plate 5, and scale frame baffle plate 3 Also equipped with a discharge nozzle 6 and a control rod 7; the sensor 2 is a pressure sensor; the angle α between the discharge nozzle 6 and the scale frame baffle 3 is 77°.

[0008] When working, hang the cement bag 8 on the discharge nozzle 6, press the cement bag 8 tightly with the bag press 4, and start filling the cement. At the same time, the sensor 2 weighs dynamically, and stops filling when the predetermined weight is reached. Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com