Connector detecting device and connector detecting method

A detection device and detection method technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of increasing contact impedance, not having too much influence on the circuit, temperature rise, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

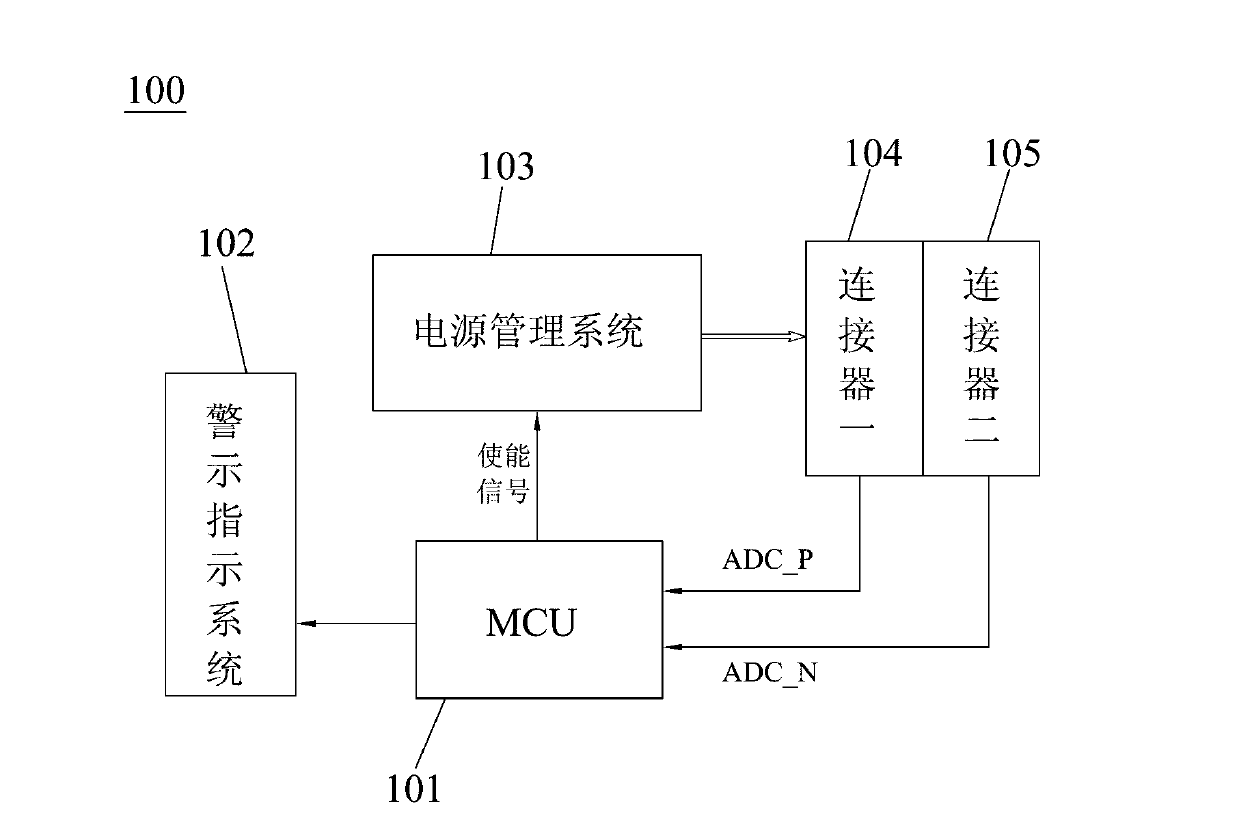

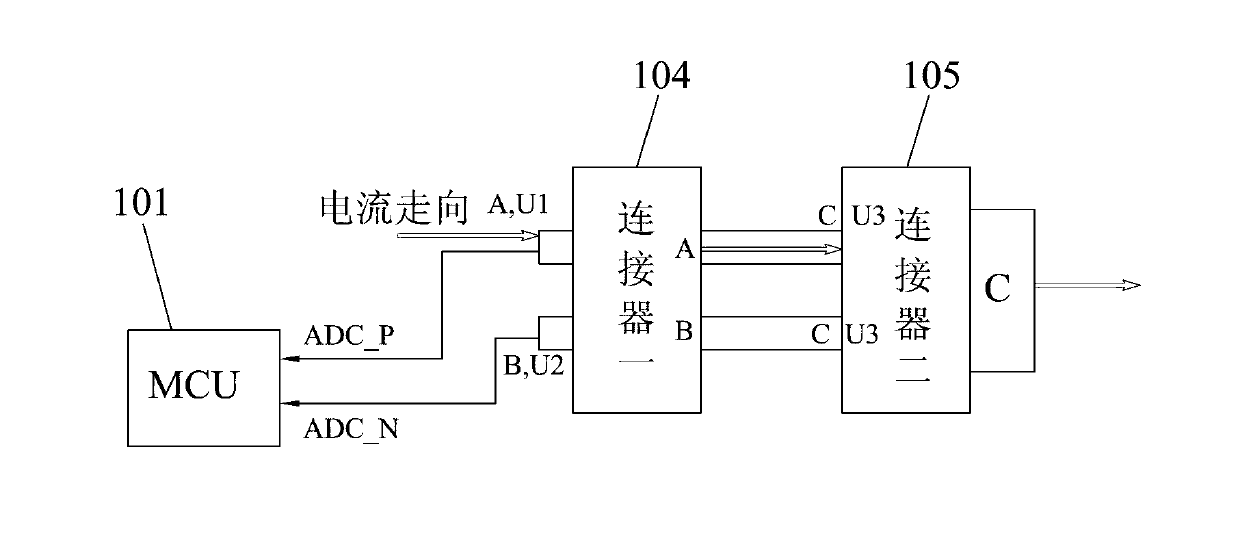

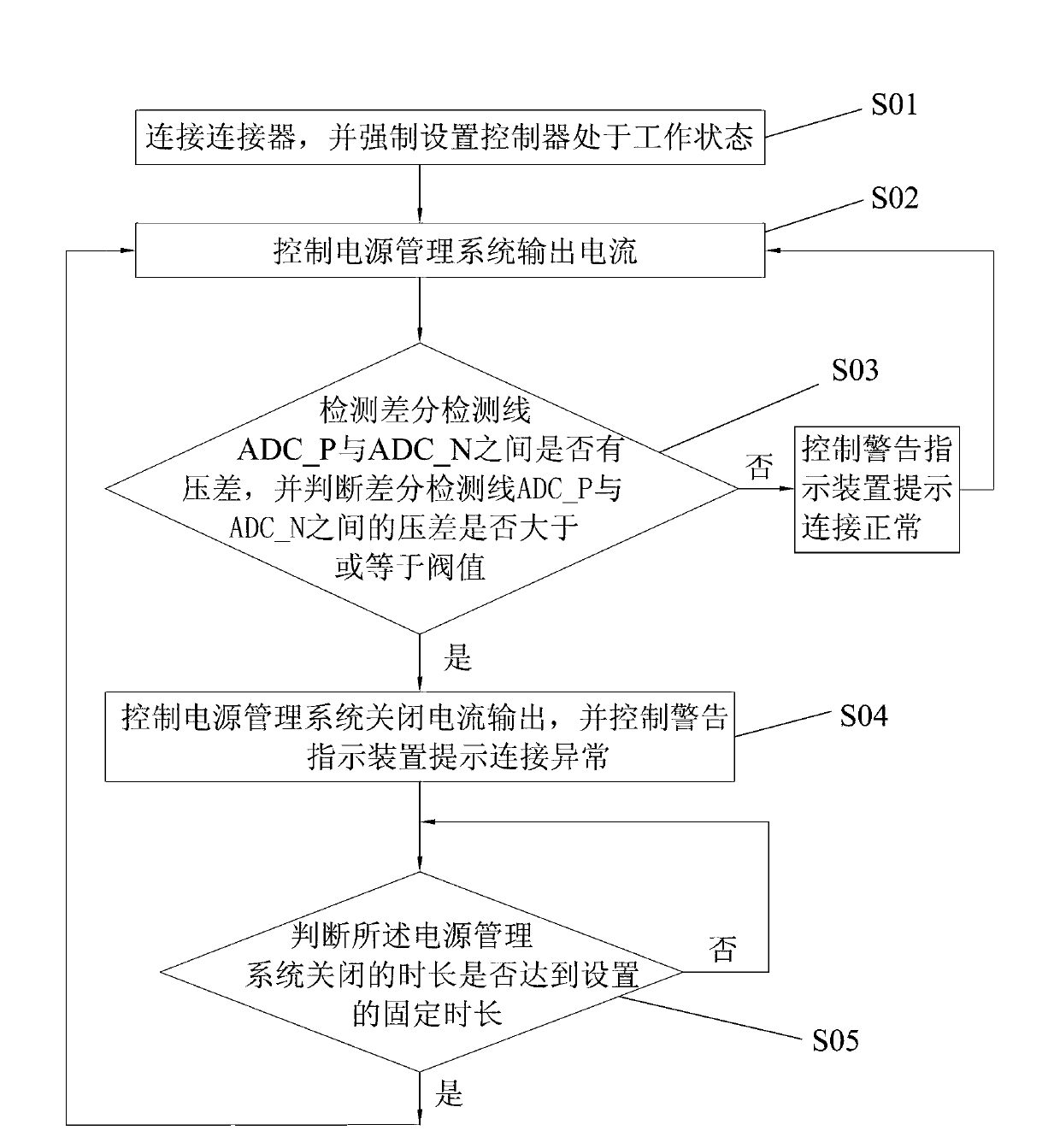

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. The connector detection device 100 of the present invention is used for real-time detection of the contact status of the connector passing through the high current, to determine whether the connection of the connector is normal, and to determine whether to output a high current, thereby preventing the connector from being damaged due to excessive heat. burn out. Wherein, the "connector" generally refers to all connectors of the mobile communication terminal that pass through a large current, for example, the "connector" can be a battery connector in a mobile phone, or a USB connector of an adapter, etc. Certainly not limited thereto, this is a technology well known to those skilled in the art.

[0028] Such as figure 1 , figure 2 As shown, the connector detection device 100 of the present invention includes a controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com