Elevating device of working face of high-voltage insulator chain

A technology for high-voltage insulators and working surfaces, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high physical energy consumption and safety risks, and difficult operations for staff, and achieve the effects of reducing operation safety risks, reducing work burden, and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

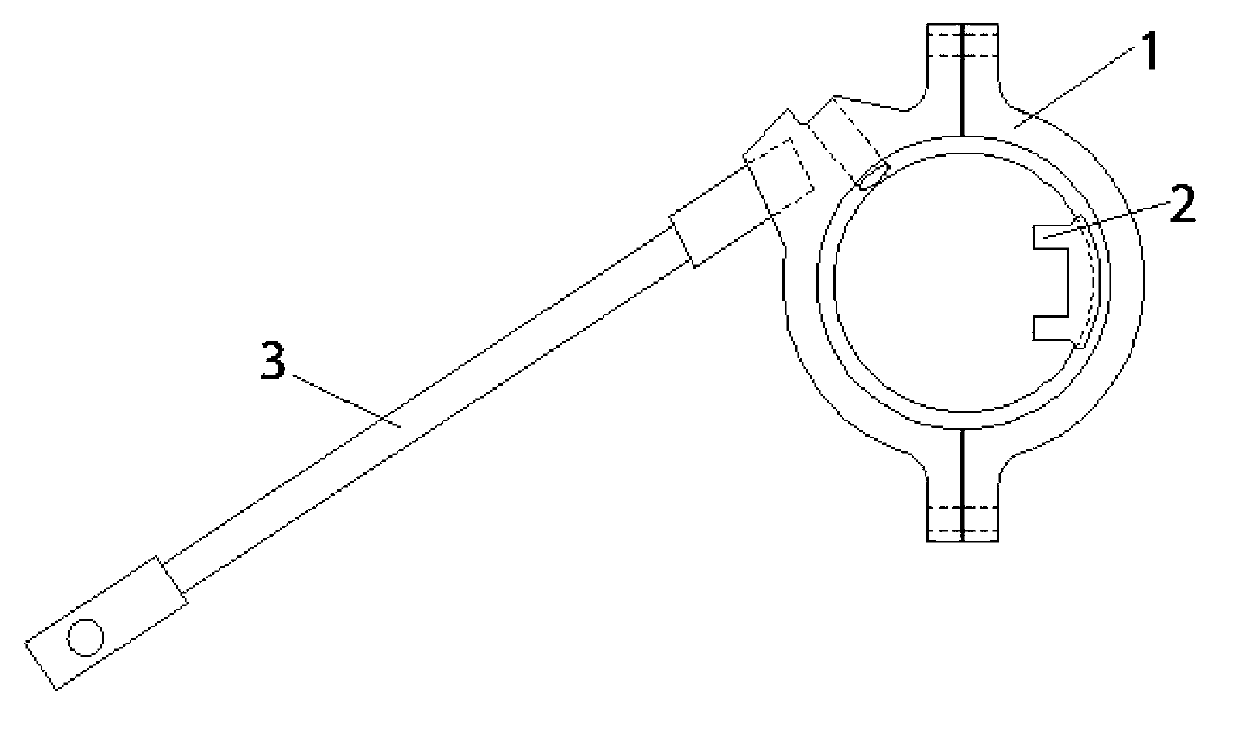

[0012] Such as figure 1 As shown, the present invention is a high-voltage insulator string working surface elevating device, which includes an annular chuck 1, which is fixedly connected to one end of a support rod 3, and is opened at the other end of the support rod 3. There are through holes. Among them, the supporting rod 3 and the annular chuck 1 are specifically threaded, and the annular chuck 1 includes two half rings, which are detachably connected by fasteners between the two half rings. The inner wall of 1 is provided with a boss 2, and the boss 2 is specifically a U-shaped boss. Also included is an insulating pulley connected to the through hole on the support rod.

[0013] The using method of the present invention is:

[0014] When in use, first use the ring-shaped chuck 1 to cover the insulator, align the boss 2 on the inner wall of the ring-shaped chuck 1 with the groove on the insulator to fix it, then connect the support rod 3 to the ring-shaped chuck 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com