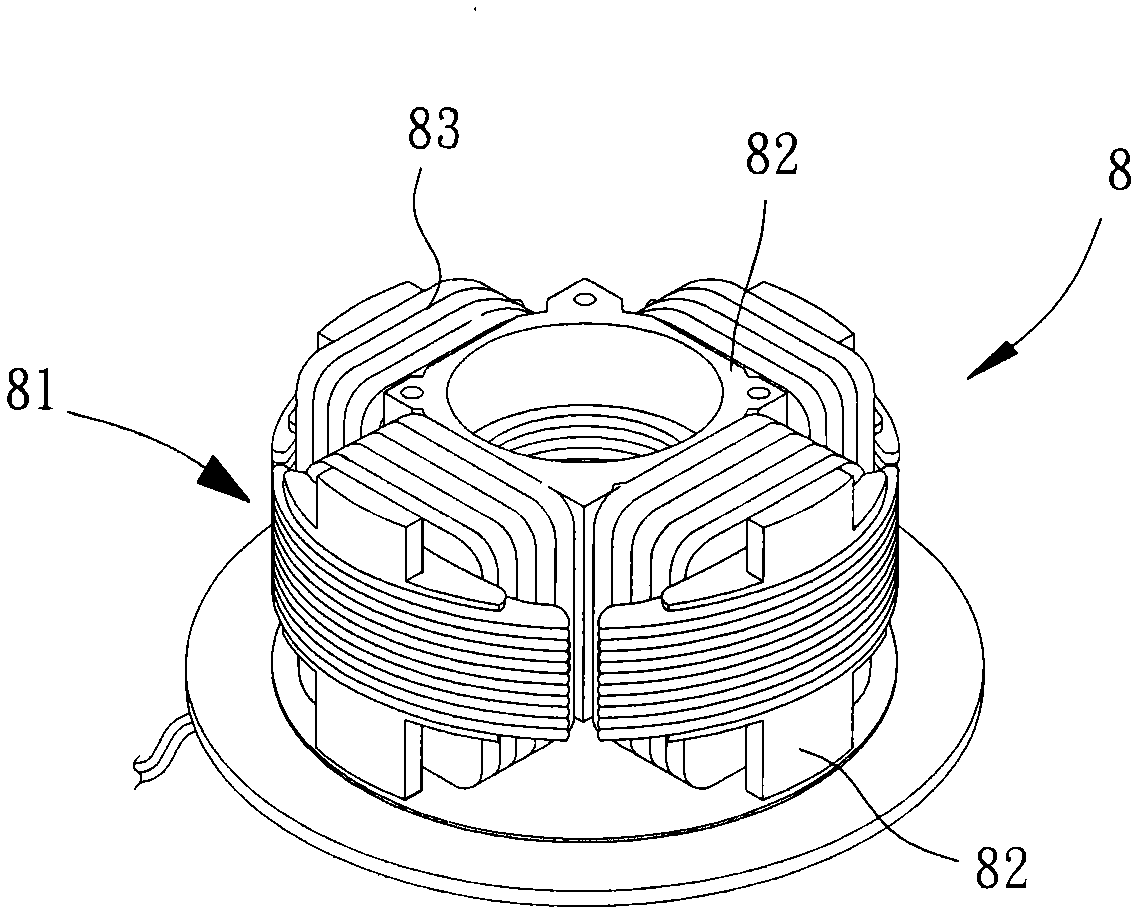

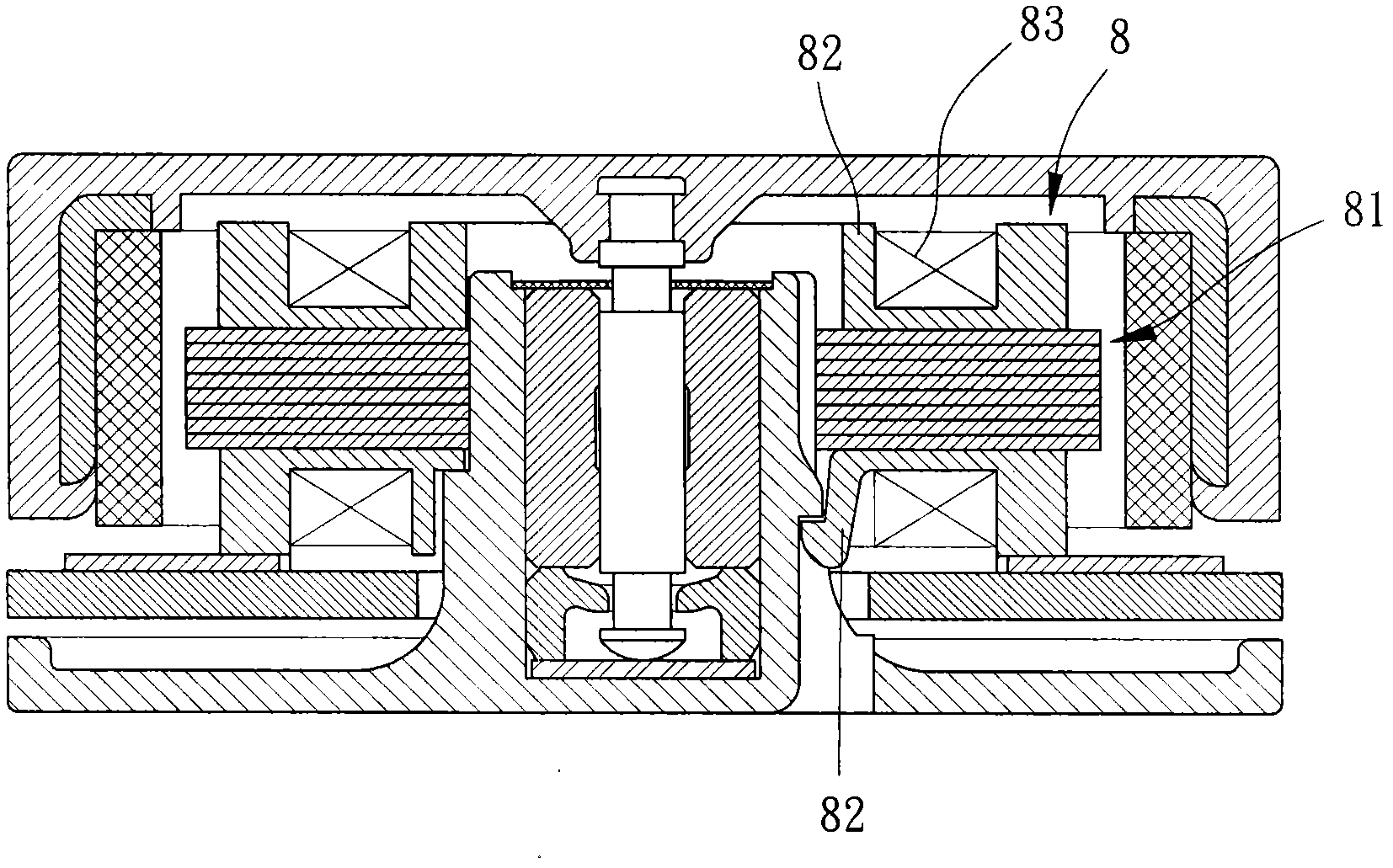

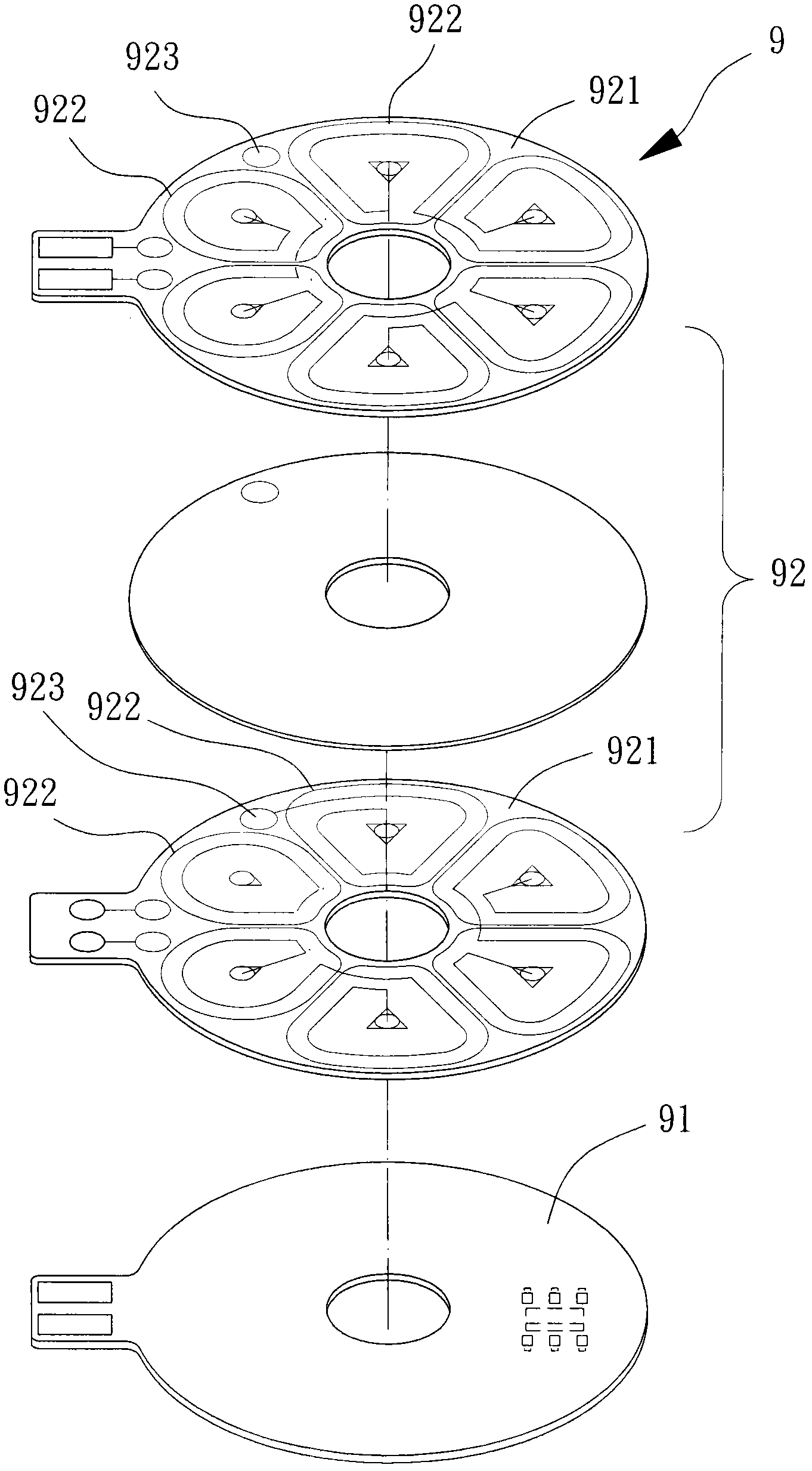

Motor and stator coil assembly and cooling fan thereof

A stator coil and heat dissipation fan technology, applied in the field of motors and their stator coil groups and heat dissipation fans, can solve the problems affecting the operation performance of the motor, and the number of winding turns or wire diameter of the coil 922 is not easy to increase, so as to improve the operation performance and improve the Running quality, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0070] The "conducting portion" defined below in the present invention refers to an electrical contact located outside the center of each coil, and the conducting portion is used to electrically connect coils of different wiring layers.

[0071] Please refer to Figure 4 and Figure 5 As shown, the motor of the first embodiment of the present invention at least includes a base 1 , a stator coil assembly 2 and a rotating member 3 . The seat body 1 can be combined with the stator coil group 2, and the stator coil group 2 can be connected with an external power supply or a drive circuit. 3 rotation actions.

[0072] The seat body 1 has a joint surface 11, and the joint surface 11 is provided with a pivot joint 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com