Rapid assembly and disassembly electric spray gun

An electric spray gun, fast technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of complex structure, inconvenient operation, etc., and achieve the effects of avoiding potential safety hazards, quick installation or disassembly, and avoiding electric leakage of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with the embodiment that accompanying drawing provides:

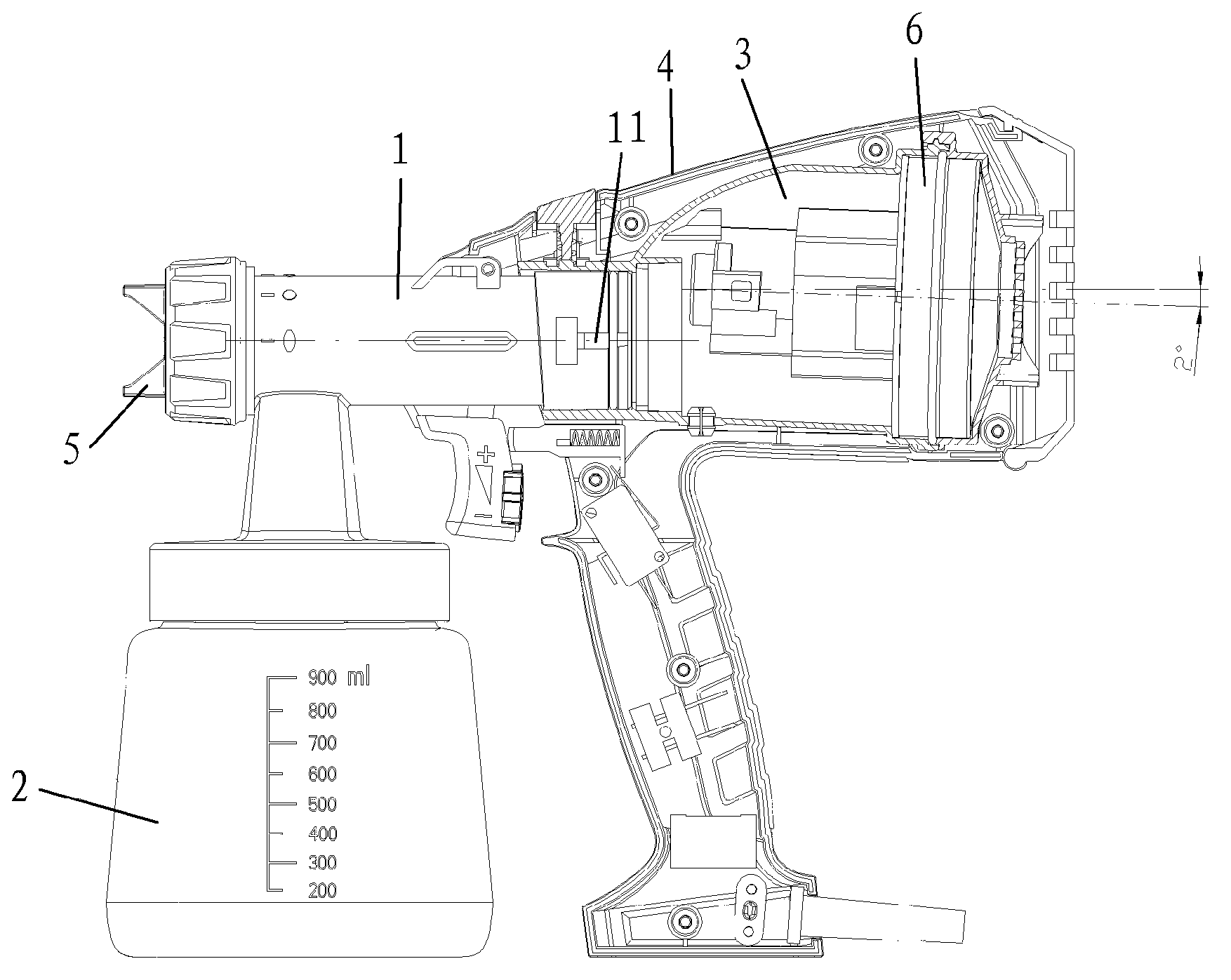

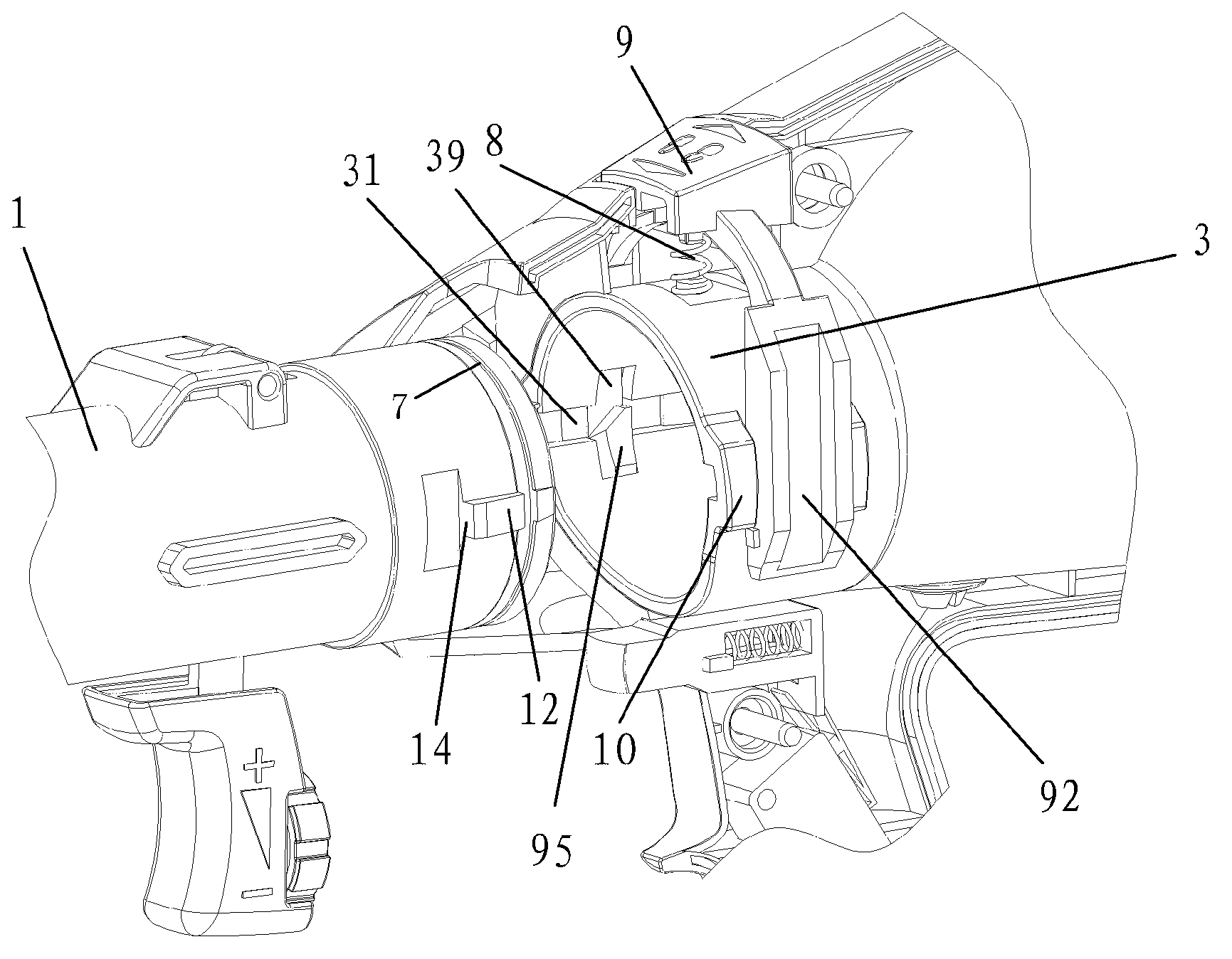

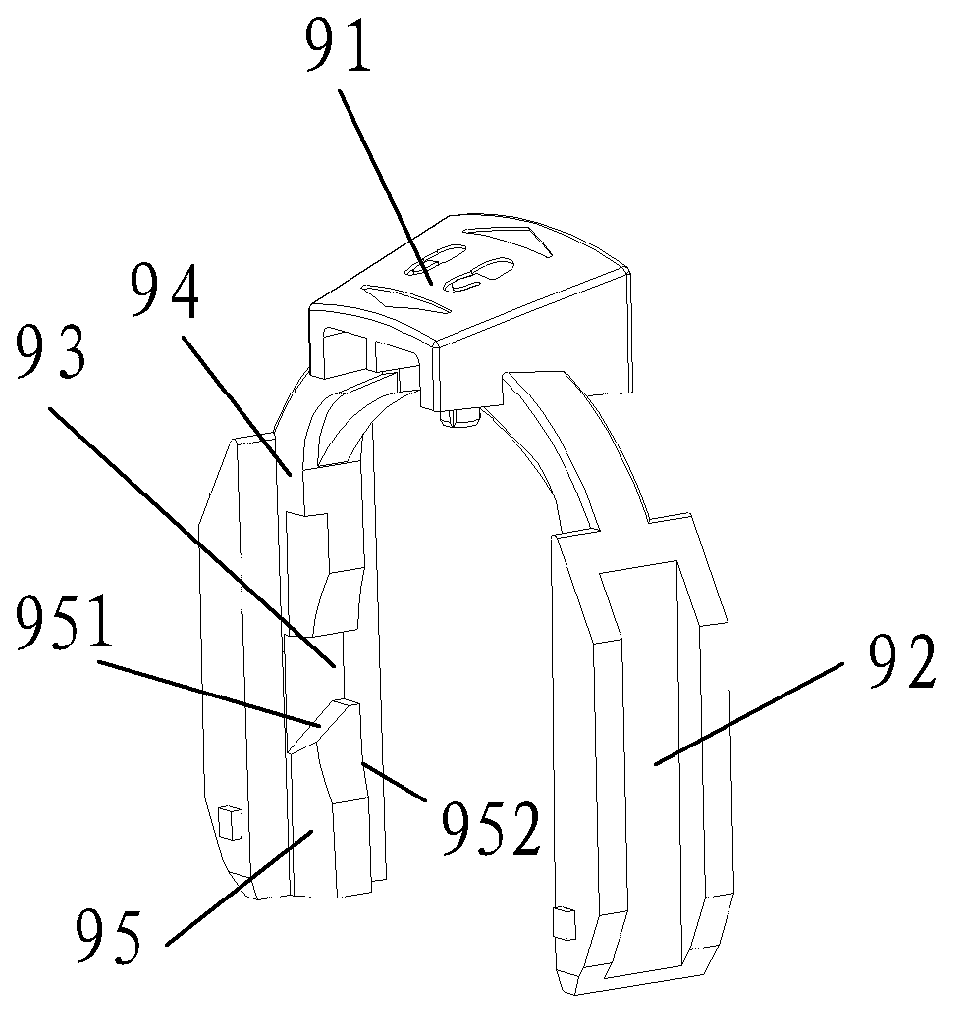

[0011] The present invention comprises liquid container 7, air nozzle 5, casing 4, gun body seat 1, inner tube 3, motor 6, air nozzle 5 is installed on the front end of gun body seat 1, and its outer diameter of the other end of gun body seat 1 is less than The inner diameter of the inner tube 3, so that the gun body seat 1 can partially extend into the inner tube 3. Inner pipe and motor are installed in the casing 4. The outer wall at one end of the gun body seat is axially provided with two projections 11, and the end face of the projections 11 away from the outer wall of the gun body seat is an inclined plane 12 with an ascending slope from the right to the nozzle direction. The inner wall of the inner tube is provided with an axial guide groove 31 and a radial through groove 39 matched with the protrusion. The button 9 is movably fitted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com