A cylinder head rotary vibration cleaning machine and cleaning method

A cleaning method and cleaning machine technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of wasting manpower, low cleaning quality, and affecting the performance of cylinders, and achieve the effect of saving manpower and improving cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

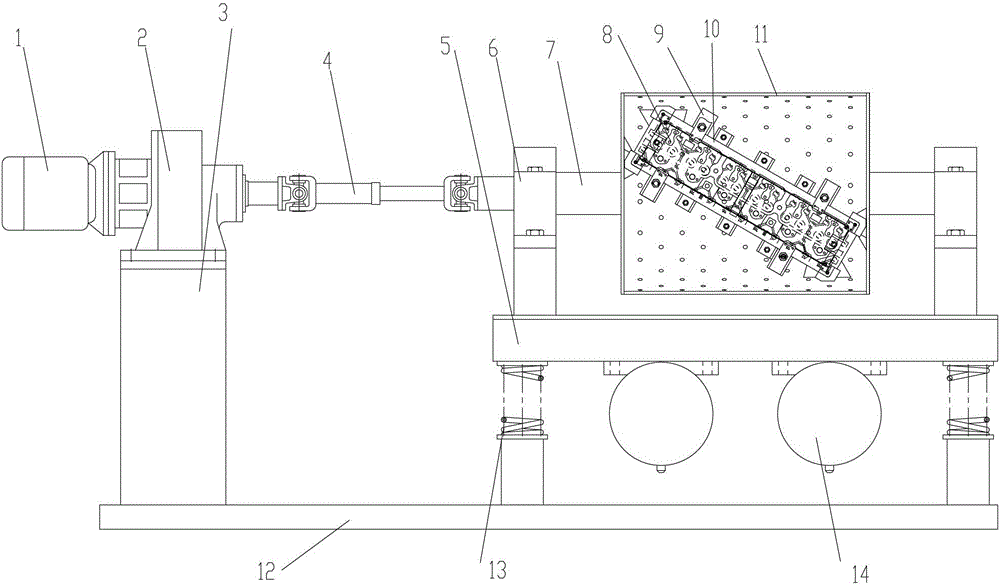

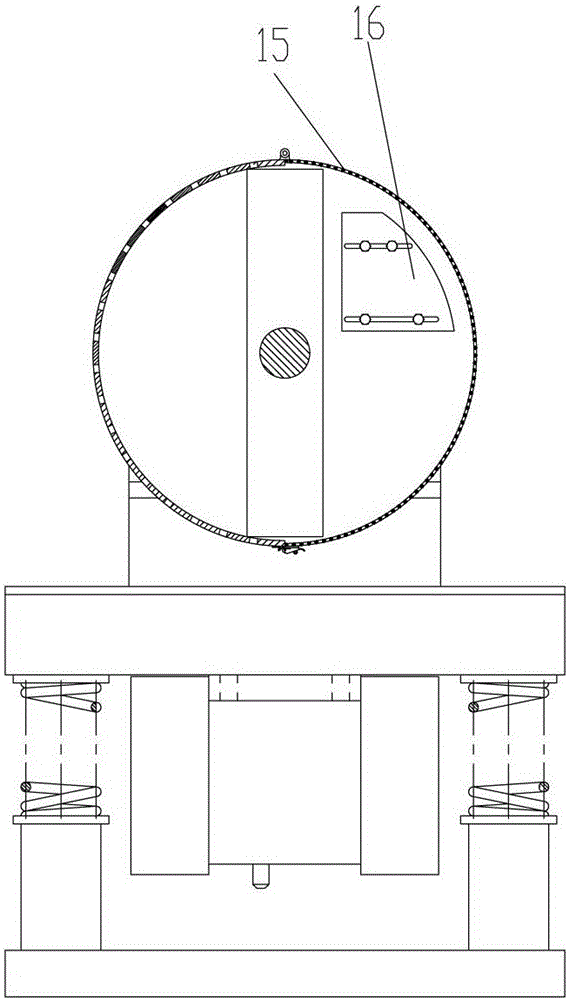

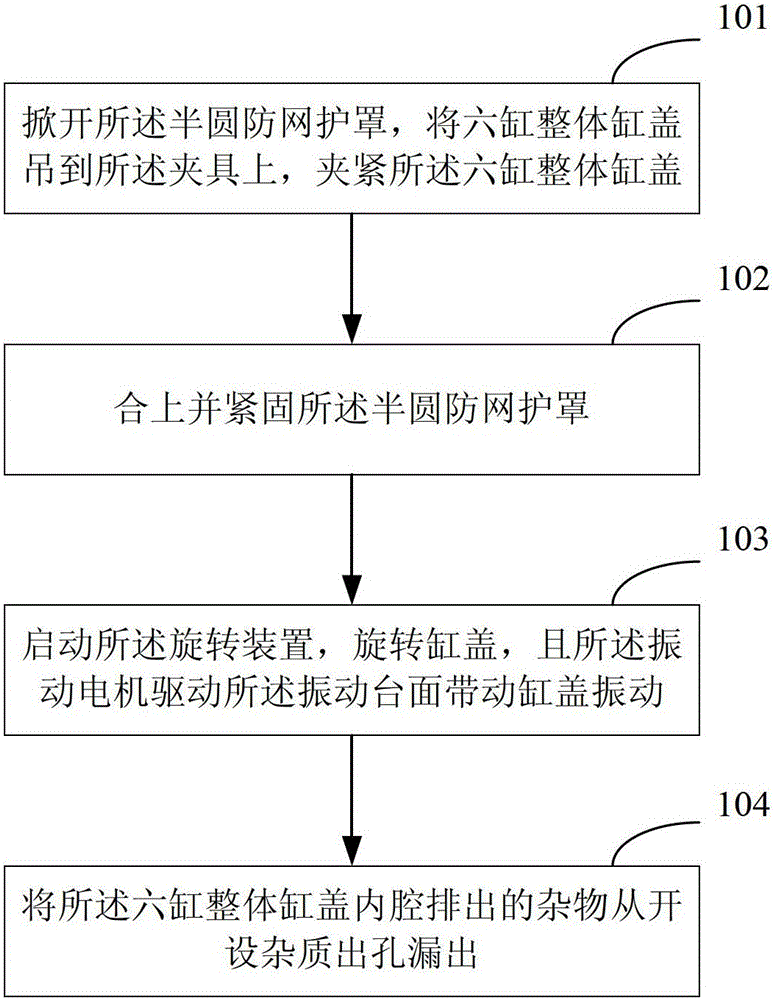

[0031] Embodiment 1 of the present invention provides a cylinder head rotary vibration cleaning machine, which is applied to cleaning a six-cylinder integral cylinder head, such as figure 1 and figure 2 As shown, it includes: a bottom frame 12; a vibrating table top 5, which is installed on the bottom frame 12 through a spring 13, and a vibrating motor 14 is installed; a semi-cylindrical body 11 with a rotating shaft 7, passed through at least two bearing seats 6 Installed on the vibrating table surface 5, there is a hole for impurities; the rotating shaft 7 is driven by the rotating device 1 through the reducer 2, the support column 3 and the universal coupling 4 in turn; the bottom frame of the fixture 9 is arranged on the In the semi-cylindrical body 11, such as welding; the fixture 10 is detachably installed obliquely on the bottom frame 9 of the fixture, and is used to fix the six-cylinder integral cylinder head 8. After the fixture 10 rotates around the rotation axis, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com