Hydraulic expander for repairing steel coil core

A hydraulic expander technology, which is applied in the field of hydraulic expanders and hydraulic expanders for repairing steel coil cores, can solve the problems of workers falling, difficult operations, and high operating intensity, so as to avoid unsafe conditions Factors, reduce the difficulty of the operation, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

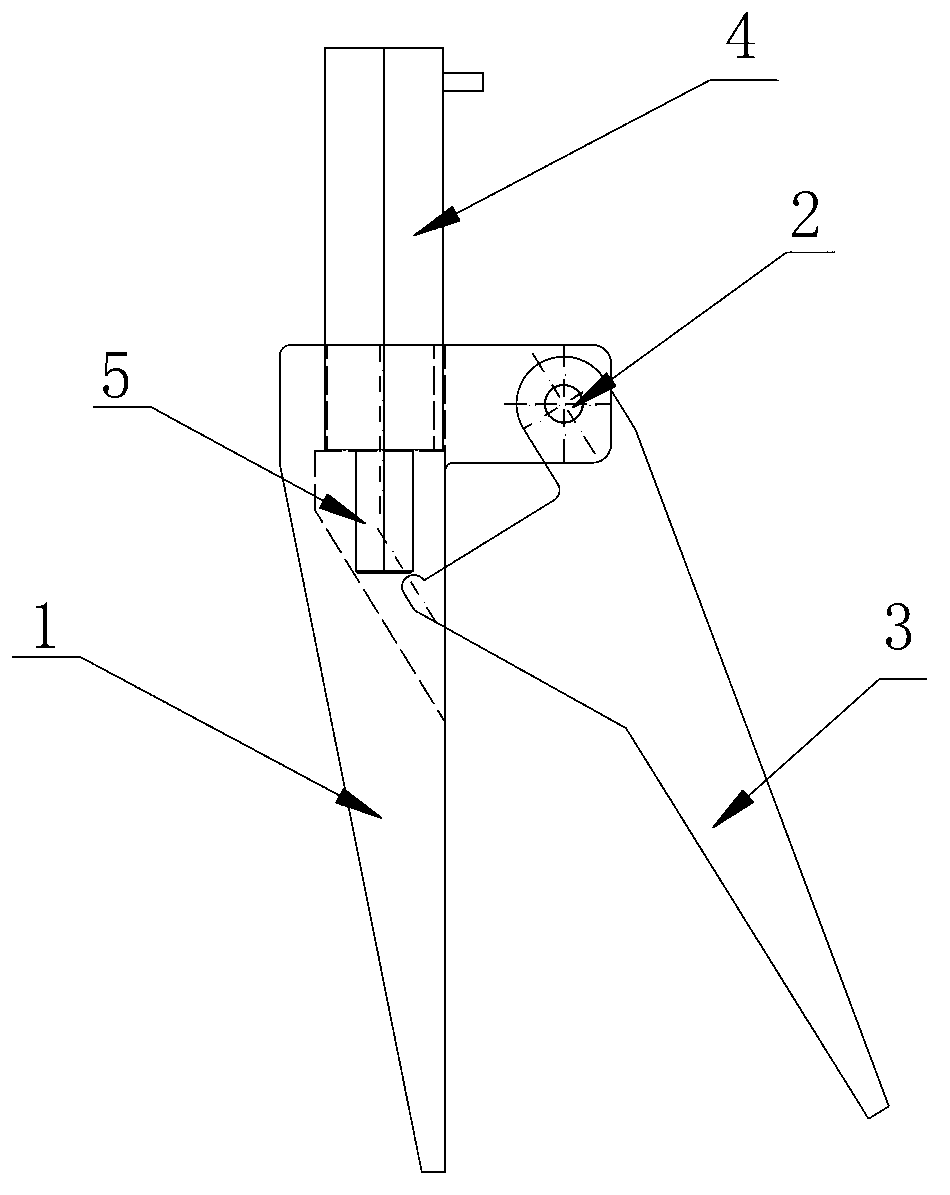

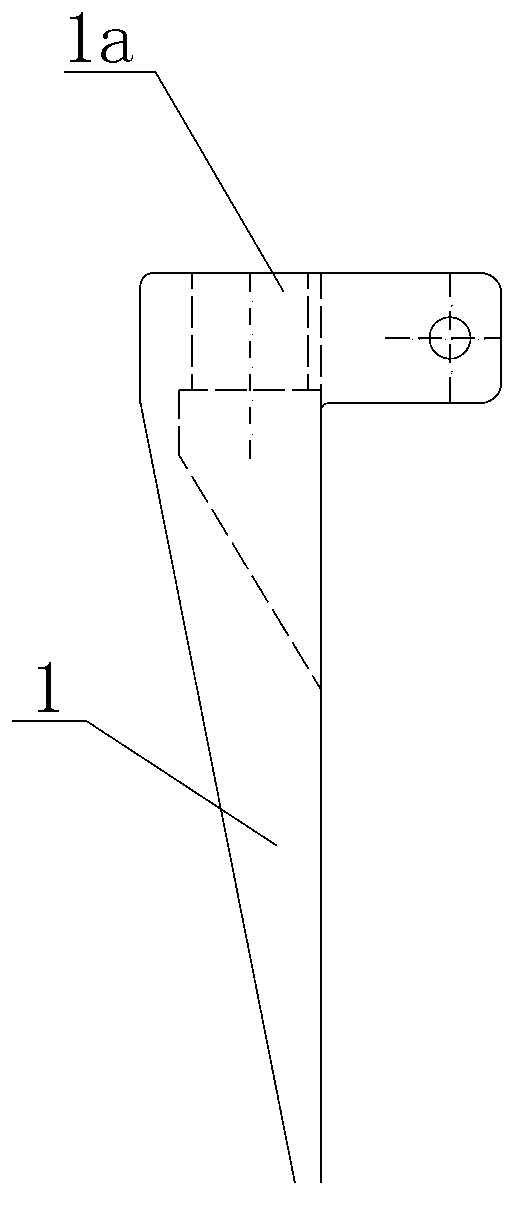

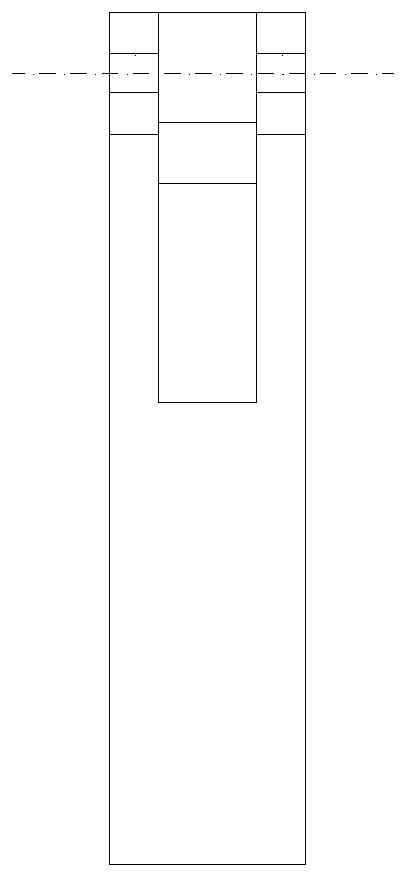

[0030] Such as figure 1 As shown, the hydraulic expander for repairing the coil core of a steel coil includes an L-shaped outer plier arm 1, the end of the outer plier arm is connected to an inner plier arm 3 through a pivot 2, and the outer plier arm 1 Set opposite to the inner pliers arm 3 , the outer pliers arm 1 has a shaft hole 1a, and an oil cylinder 4 is installed in the shaft hole, and the piston 5 of the oil cylinder presses against the upper end surface of the inner pliers arm 3 .

[0031] Preferably, the length of the outer tong arm is 350mm, and the length of the inner tong arm is 345mm.

[0032] The width of the outer clamp arm is 80mm.

[0033] The width of the inner pincer arm is 40mm.

[0034] The maximum expansion angle of the inner and outer pincer arms is 32°.

[0035] The working principle of the present invention is that the piston in the oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com