Rope guider for mining puffer

A small winch and rope arrangement technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of high cost, poor product consistency, occupying the power of the winch motor, etc., to improve the service life, reduce the installation accuracy and processing. The effect of production difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

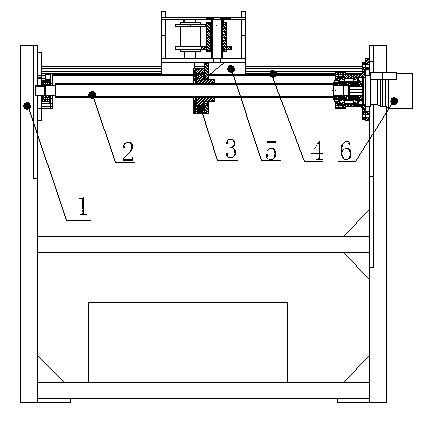

[0024] Such as figure 1 As shown, the rope extractor for a small winch provided in this embodiment includes a bracket, a guiding motion actuator, a steel rope deviation detection mechanism, a hydraulic motor 6 and a three-position four-way hydraulic valve 16 that controls the operation of the hydraulic motor 6. The above-mentioned guiding motion actuator includes a trapezoidal screw 2, a self-aligning screw nut 3 threaded with the trapezoidal screw 2, a double-axis integral guide rail 4 and a guide rail slider 5 matched therewith, the trapezoidal screw 2 and the double The axial integral guide rail 4 is arranged laterally on the support 1 .

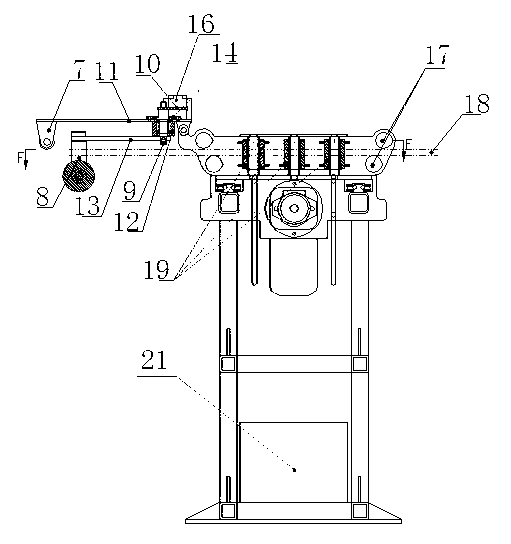

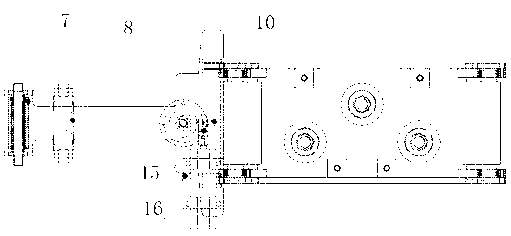

[0025] Such as figure 2 , Figure 5 , Image 6 As shown, the steel rope deviation detection mechanism includes a rope pressing roller mechanism 7, a rope swinging roller mechanism 8, a driven shaft 9 and a shift fork 10, and the rope pressing roller mechanism 7 passes through a first connecting rod 11, a first bearing 12, The driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com