Manufacturing method of functional vacuum glass

A vacuum glass and manufacturing method technology, applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve the problems of undiscovered patent documents, impact on sound insulation, heat insulation, limited production area, etc., and achieve scientific design , high sound insulation and heat insulation effect, and the effect of expanding the technical field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for manufacturing functional vacuum glass, the steps are:

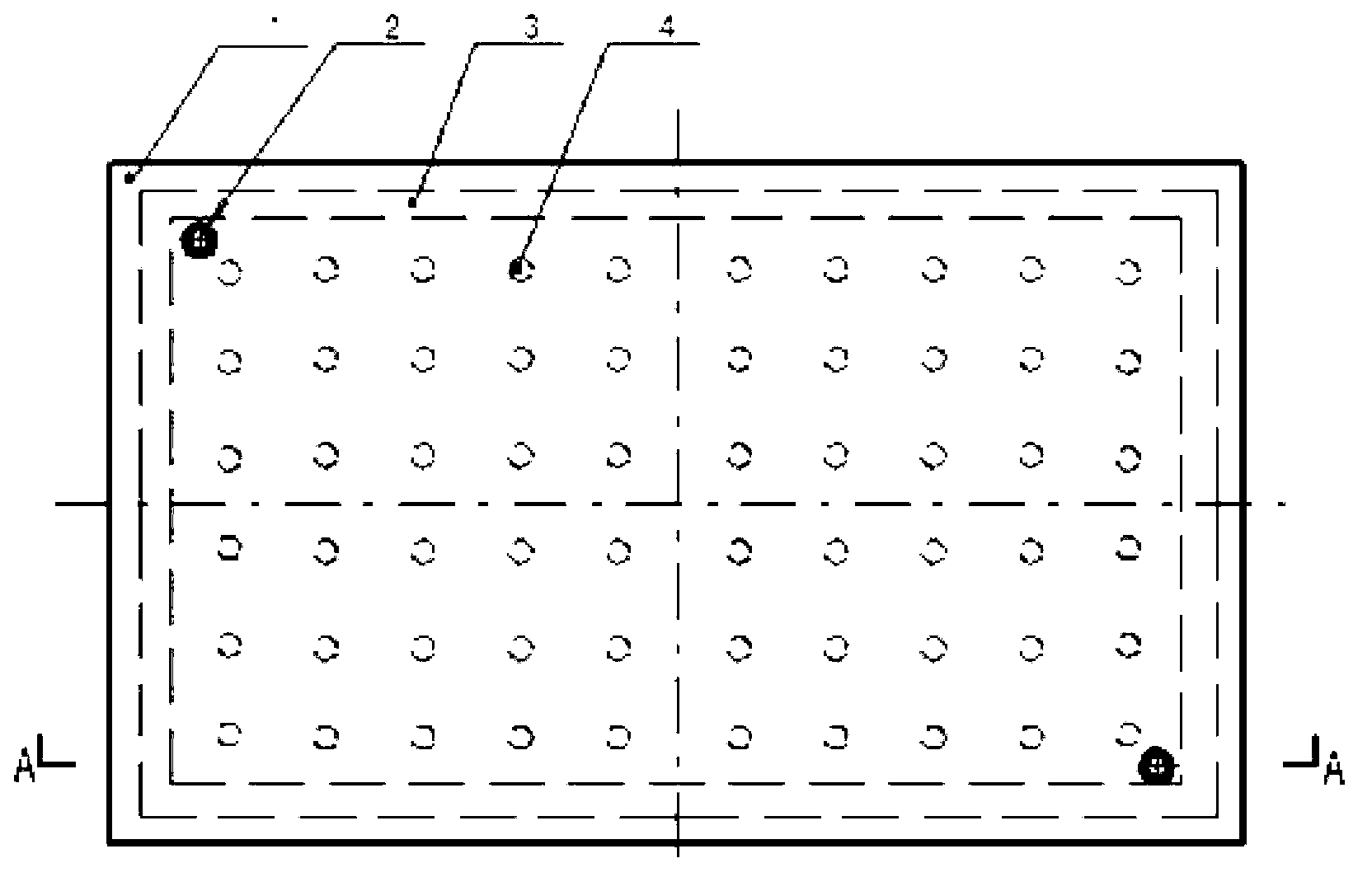

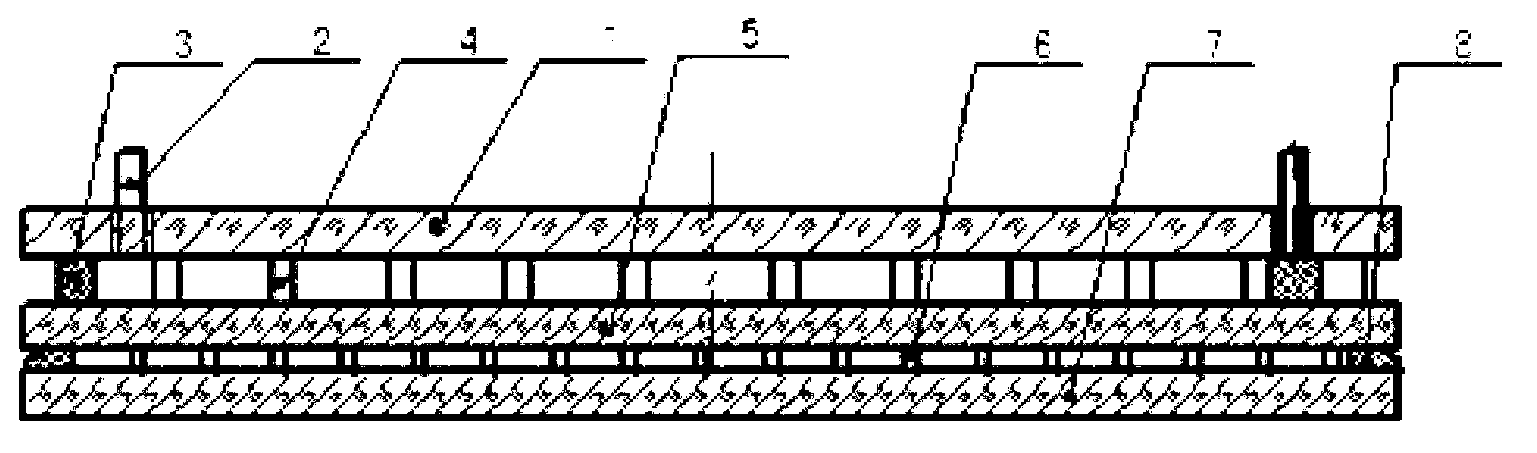

[0027] (1) Place the finished vacuum glass on the operating table. The vacuum glass includes the top glass 5 and the base glass 7, and supports 6 are evenly spaced between them, and the edge between the top glass and the base glass is sealed with Edge sealing with low melting point glass powder8. Place the flat glass on the vacuum glass (the top glass and the substrate glass are both acceptable, the attached glass in this embodiment is the top glass) on the operating table, and place the support body 4 on the upper surface at an even interval of 3-5 cm. The support body includes glass, ceramics, metal support column, metal wire or metal sheet, and the height of the support body is 0.5-25mm; for the cylindrical support body, its diameter is Ф1-15mm;

[0028] (2) Place the square frame 3 coated with low-melting point glass powder on the upper and lower ends on the four sides of the upper glass of the va...

Embodiment 2

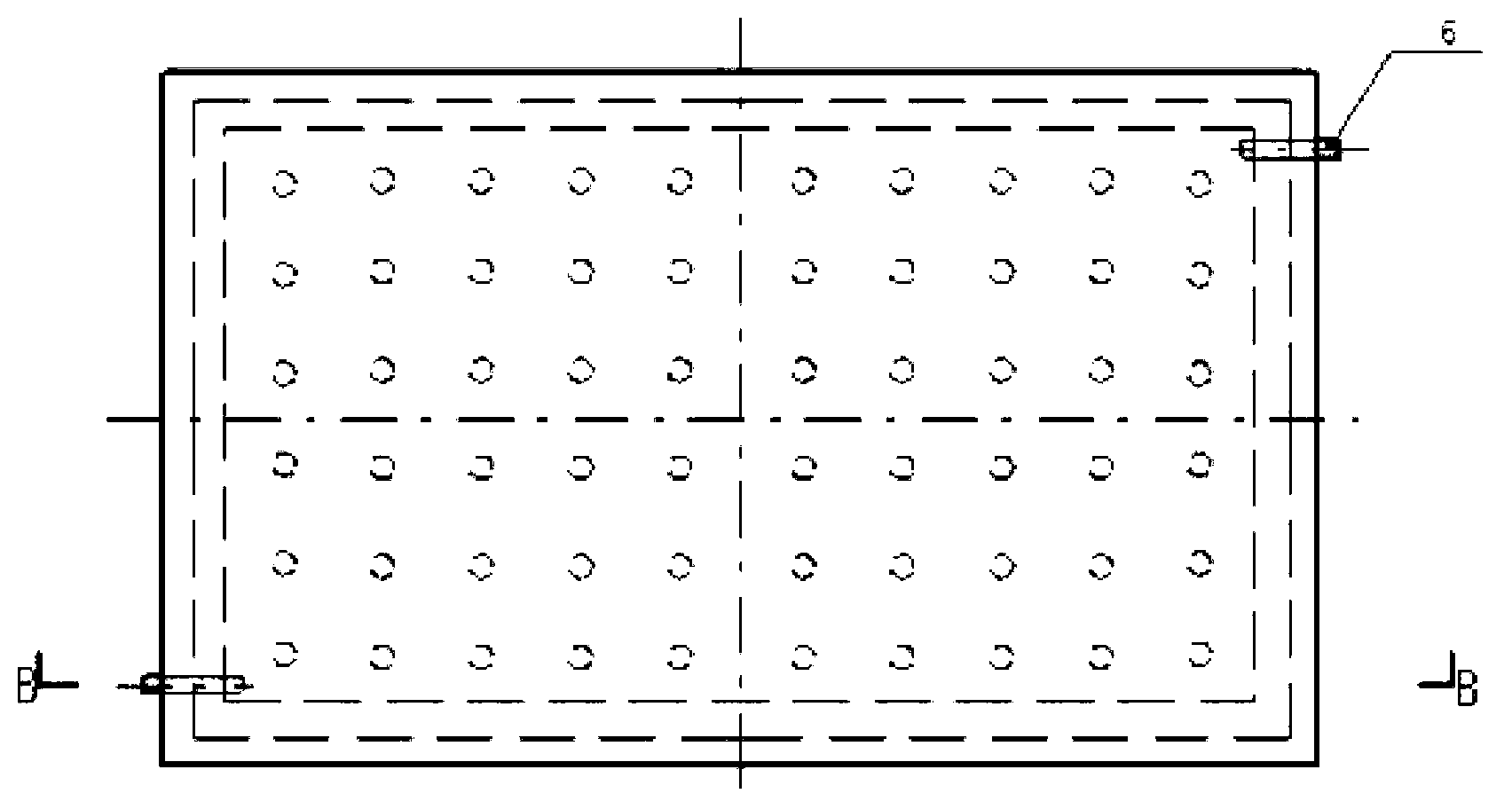

[0038] Only the glass tube 9 is fixed on the square frame, that is, the exhaust glass tube is placed on the side or corner of the square frame, and a concave hole can be made on the square frame and between the corresponding flat glass and the upper glass in advance. The tank is then filled with placed glass tubes and low-melting glass powder.

[0039] In the accompanying drawings of this embodiment, the two glass tubes are also installed diagonally.

[0040] The unrecited part is the same as the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com