Inner paint of metal beverage food can and preparation method and application thereof

A technology for food cans and beverages, applied in anti-corrosion coatings, polyester coatings, lining/internal coatings, etc., which can solve problems such as high cost and multiple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

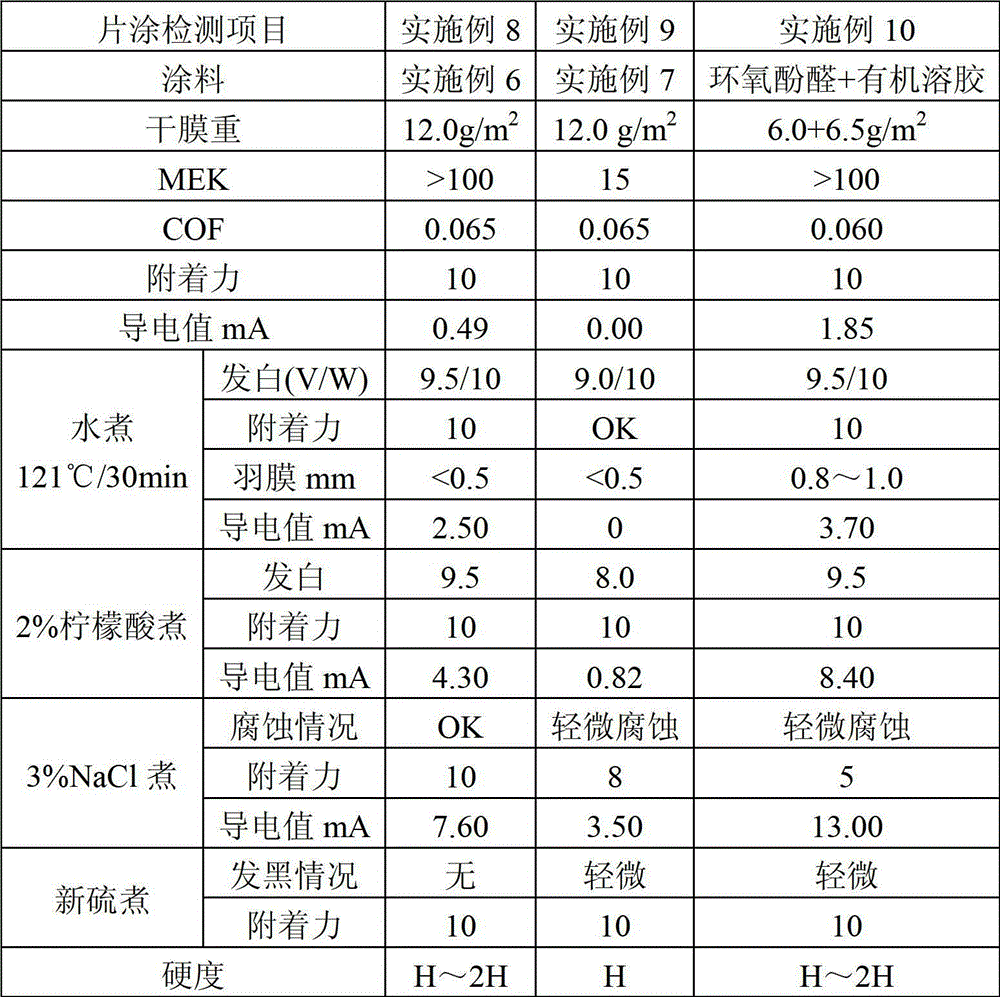

Examples

Embodiment 1

[0065] Synthesis of Saturated Polyester:

[0066] (1) Put 137.01g of terephthalic acid, 87.03g of isophthalic acid, 60.06g of 1,6-hexanediol and 128.02g of neopentyl glycol into the Add 0.50g of dibutyltin oxide to a 4-necked flask with nitrogen inlet, react at 190°C for 1 hour, and control the temperature of the distillation head not to exceed 102°C;

[0067] (2) Then raise the temperature of the system to 240±3°C to react within 3 hours, and control the temperature of the distillation head to not exceed 102°C; keep warm until the system is transparent and the temperature of the distillation head is at 60°C.

[0068] (3) Cool down to 180°C, add 50.02g of isophthalic acid; then raise the temperature of the system to 230±3°C for 2 hours, keep warm until the system is transparent, keep warm for 1h after being transparent, and remove the fractionation column;

[0069] (4) Replace the fractionation column with a water separator, add 30g of xylene, raise the temperature to 210-215...

Embodiment 2

[0073] Synthesis of Saturated Polyester:

[0074] (1) Put 115.01g of terephthalic acid, 140.00g of isophthalic acid, 60.05g of 1,6-hexanediol and 130.05g of neopentyl glycol into the Add 0.50g of dibutyltin oxide to a 4-necked flask with nitrogen inlet, react at 190°C for 1 hour, and control the temperature of the distillation head not to exceed 102°C;

[0075] (2) Then raise the temperature of the system to 240±3°C to react within 3 hours, and control the temperature of the distillation head to not exceed 102°C; keep warm until the system is transparent and the temperature of the distillation head is at 60°C.

[0076] (3) Cool down to 180°C, add 30.04g of sebacic acid; then raise the temperature of the system to 230±3°C for 2h, keep it warm for 1h, and remove the fractionating column;

[0077] (4) Replace the fractionation column with a water separator, add 30.00g of xylene, raise the temperature to 210-215°C, and keep it under reflux for 2 hours.

[0078] (5) Take a small ...

Embodiment 3

[0081] Synthesis of Saturated Polyester:

[0082] (1) 30.02g of terephthalic acid, 50.00g of isophthalic acid, 41.04g of sebacic acid, 14.42g of 1,4-cyclohexanedimethanol, 74.60g of neopentyl glycol, and 4.00g of trimethylolpropane Add to a 4-necked flask equipped with a stirrer, thermometer, rectifying column, condenser and nitrogen inlet, add 0.20g of dibutyltin oxide, react at 190°C for 1 hour, and control the temperature of the distillation head not to exceed 102°C;

[0083] (2) Then raise the temperature of the system to 240±3°C to react within 3 hours, and control the temperature of the distillation head to not exceed 102°C; keep warm until the system is transparent and the temperature of the distillation head is at 60°C.

[0084] (3) Cool down to 180°C, add 20g of isophthalic acid; then raise the temperature of the system to 230±3°C for 2 hours, keep warm until the system is transparent, continue to keep warm for 1 hour after being transparent, and remove the fractionat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com