Printing method for fabrics

A printing method and printing technology, which are applied in the fields of dyeing, textiles and papermaking, etc., can solve the problems of increased production cost, difficulty in production, poor effect, etc., and achieve the effect of delicate moiré effect, rich colors, and natural transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

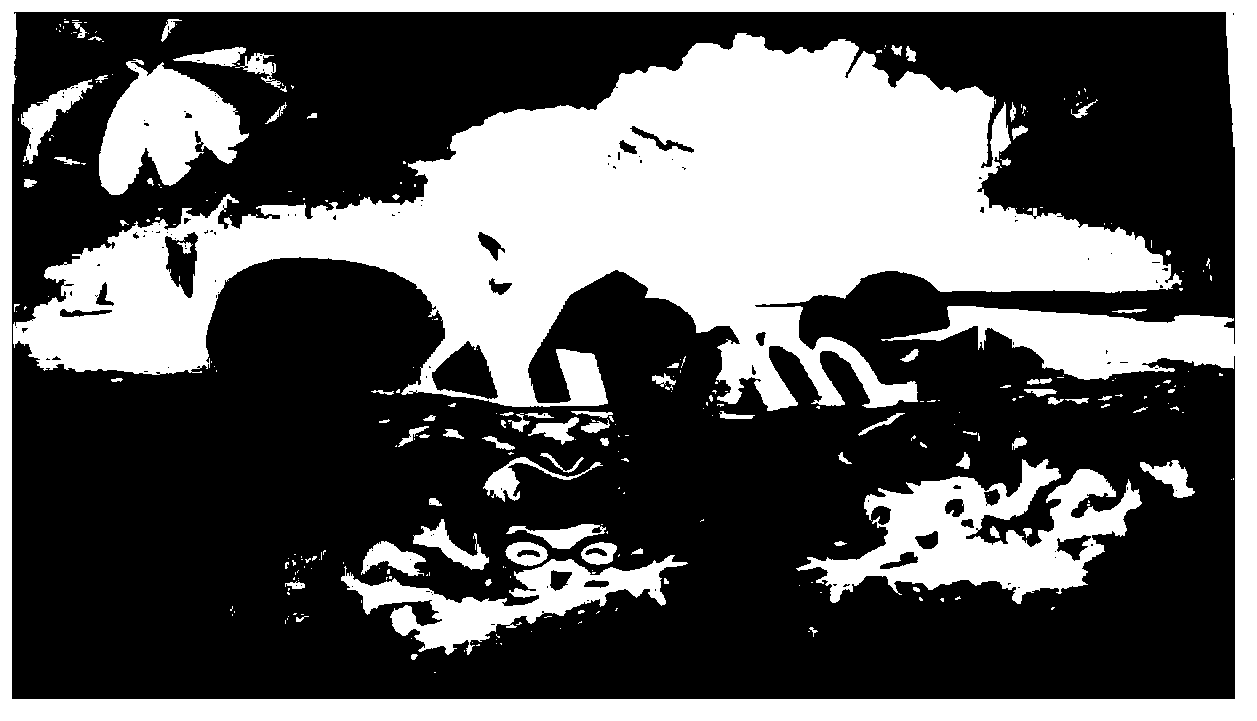

[0069] image 3 It is the sample printing pattern of the embodiment 1 of the present invention, and the material is cotton cloth, adopts the high-precision scanner that model is ES-6000HS to scan it, obtains the scanned image, utilizes the AT2000 color separation software of Hangzhou Honghua first to it Curve adjustment, detail modification, and then use the color separation software to perform color separation to obtain the cyan pattern, magenta pattern, yellow pattern, light black pattern, light cyan pattern, light red pattern, sapphire blue pattern and Black patterns, among them, cyan patterns such as Figure 4 as shown, Figure 4 It is the cyan pattern after color separation of the sample printing pattern of Example 1 of the present invention.

[0070]According to the cyan pattern, magenta pattern, yellow pattern, light black pattern, light cyan pattern, light red pattern, sapphire blue pattern and black pattern, hang the net respectively, obtain the black and white moir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com