Electric control lifting skylight structure of steel-structure industrial plant

A technology for industrial workshops and steel structures, applied to building structures, roofs, buildings, etc., can solve the problems that the natural ventilation and natural lighting of the workshop cannot be guaranteed, water vapor cannot be discharged, and do not meet the requirements, so as to achieve good lighting and ventilation effects , compact and firm structure, and the effect of ensuring the safety of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

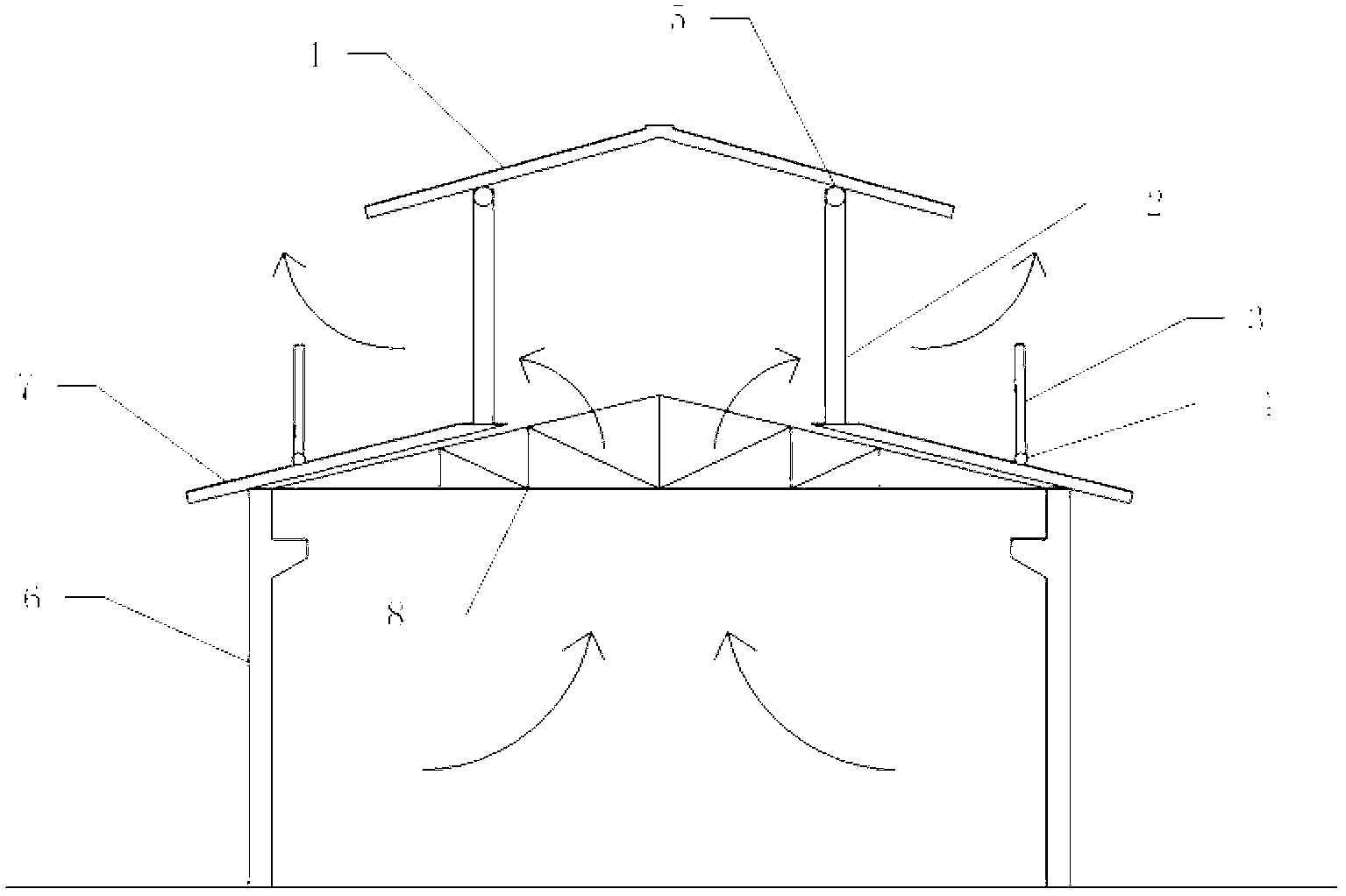

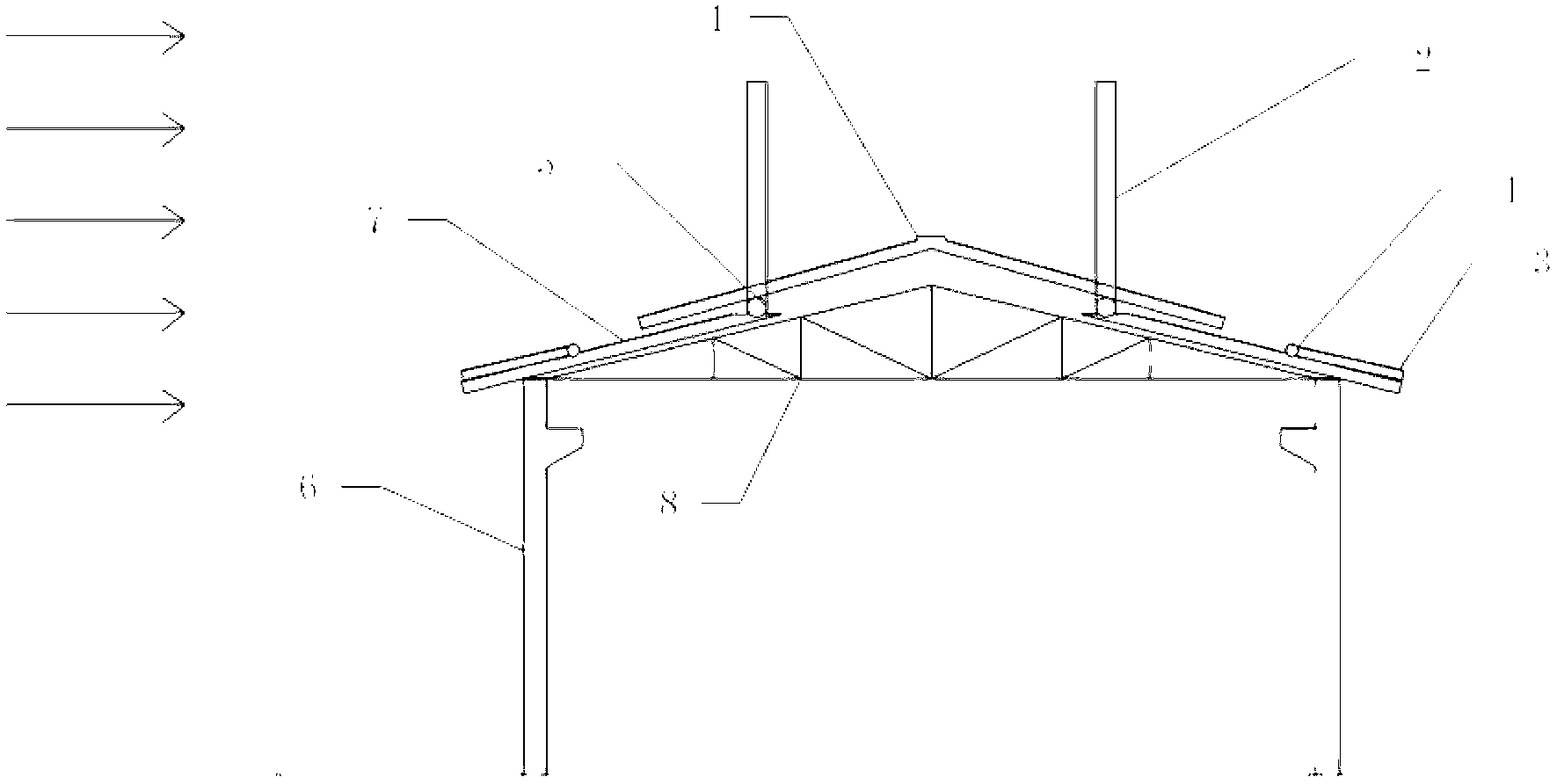

[0015] An electric control lifting skylight structure of a steel structure industrial factory building, the structure is as follows Figure 1-2 As shown, it consists of a liftable skylight ceiling 1, a skylight guide rail 2 and a windshield 3. The skylight guide rail 2 is vertically arranged on both sides of the central opening of the steel structure factory building 6 roof 7, and the liftable skylight ceiling 1 passes through the transmission The device realizes the lifting on the skylight guide rail 2, and the windshield 3 is arranged on both sides of the roof 7 of the steel structure factory building 6, and realizes the openable connection with the steel structure factory building cover 7 through the rotating shaft.

[0016] The above-mentioned transmission device is a pulley mechanism or a rack and pinion mechanism or a worm gear mechanism.

[0017] The componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com