Control mechanism of manual transmission

A manual transmission and control mechanism technology, applied to mechanical equipment, components with teeth, transmission device control, etc., can solve the problems of heavy gear selection, large space occupation, etc., achieve compact layout, reduce heaviness, and improve gear shifting The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly described below with reference to the drawings in the embodiments of the present invention.

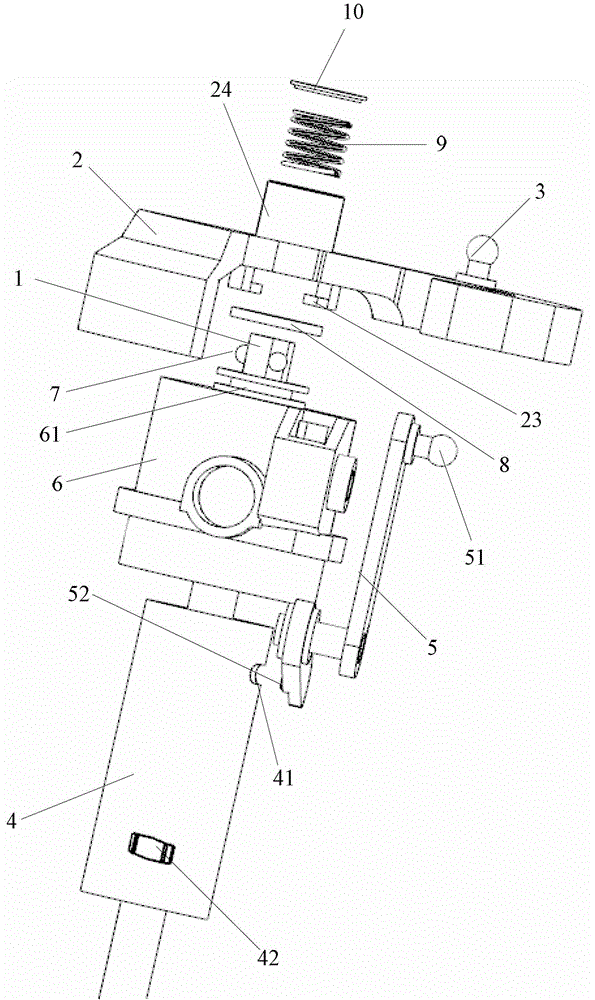

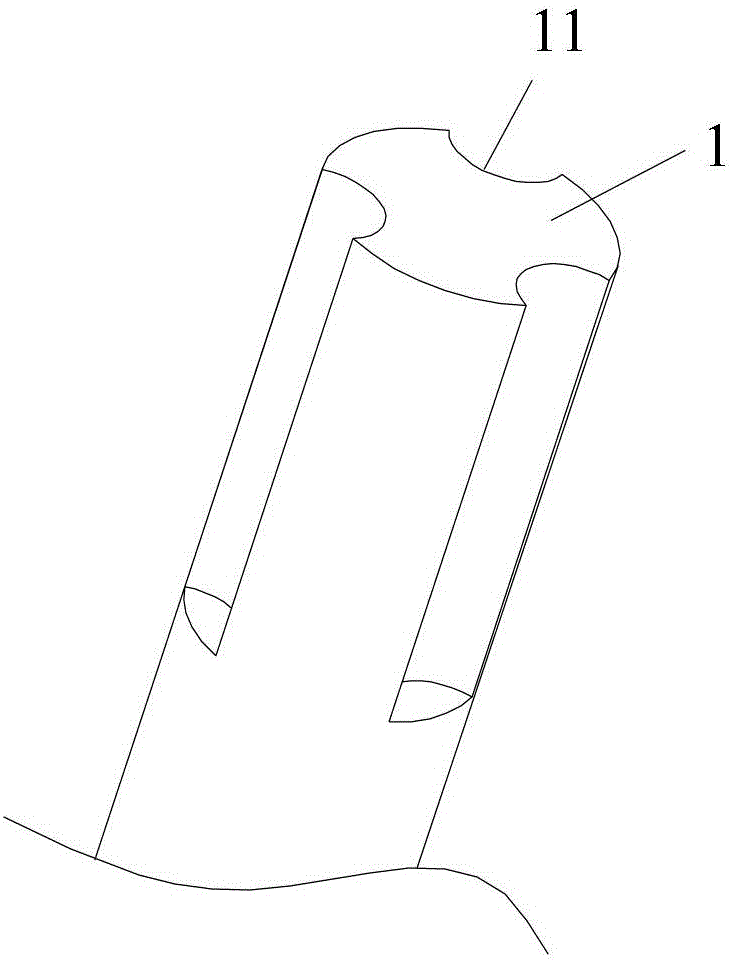

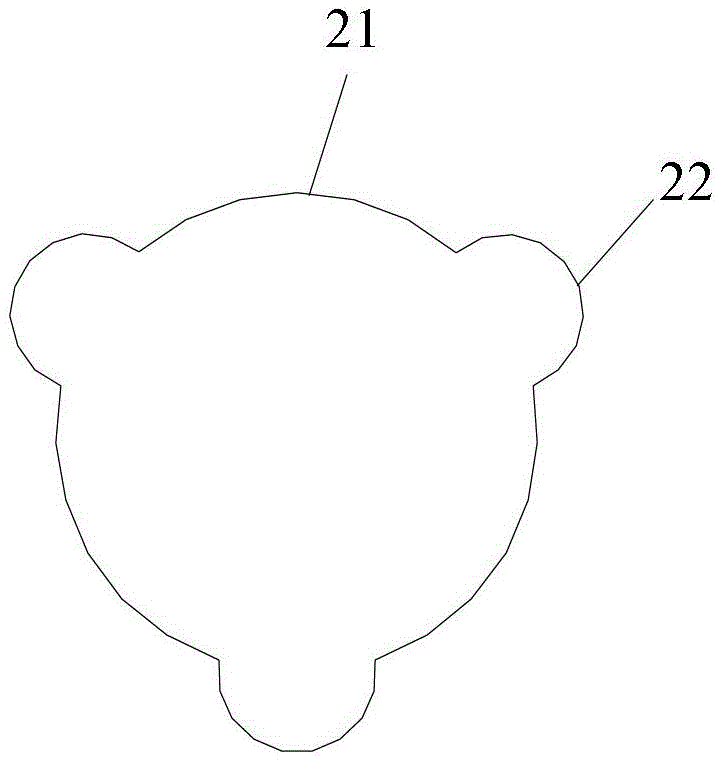

[0021] figure 1 The schematic diagram of the structure of the operating mechanism of the manual transmission provided by the embodiment of the present invention, the operating mechanism includes: a shift shaft 1, which can rotate around the shaft and move axially, and is assembled on the operating cover 6, and the operating cover 6 is connected with the casing of the transmission The body (not shown) is fixedly connected; the counterweight 2 is connected with the shift shaft 1 to move axially and rotate synchronously in the circumferential direction; the shift arm 3 is fixed on the counterweight 2, and the shift arm 3 is The ball pin is connected with the shift lever in the cab through a cable not shown in the figure.

[0022] In the control mechanism provided by the embodiment of the present i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap