Orthogonal polarization fiber bragg grating vector torsion sensing device and detection method thereof

An orthogonal polarization and fiber grating technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not being able to obtain polarization state energy information at the same time, not being able to realize vector torsion detection, and large volume of the sensing system, so as to avoid Splice loss and unpredictable polarization interference, guaranteed mechanical strength and polarization stability, and adjustable scanning bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

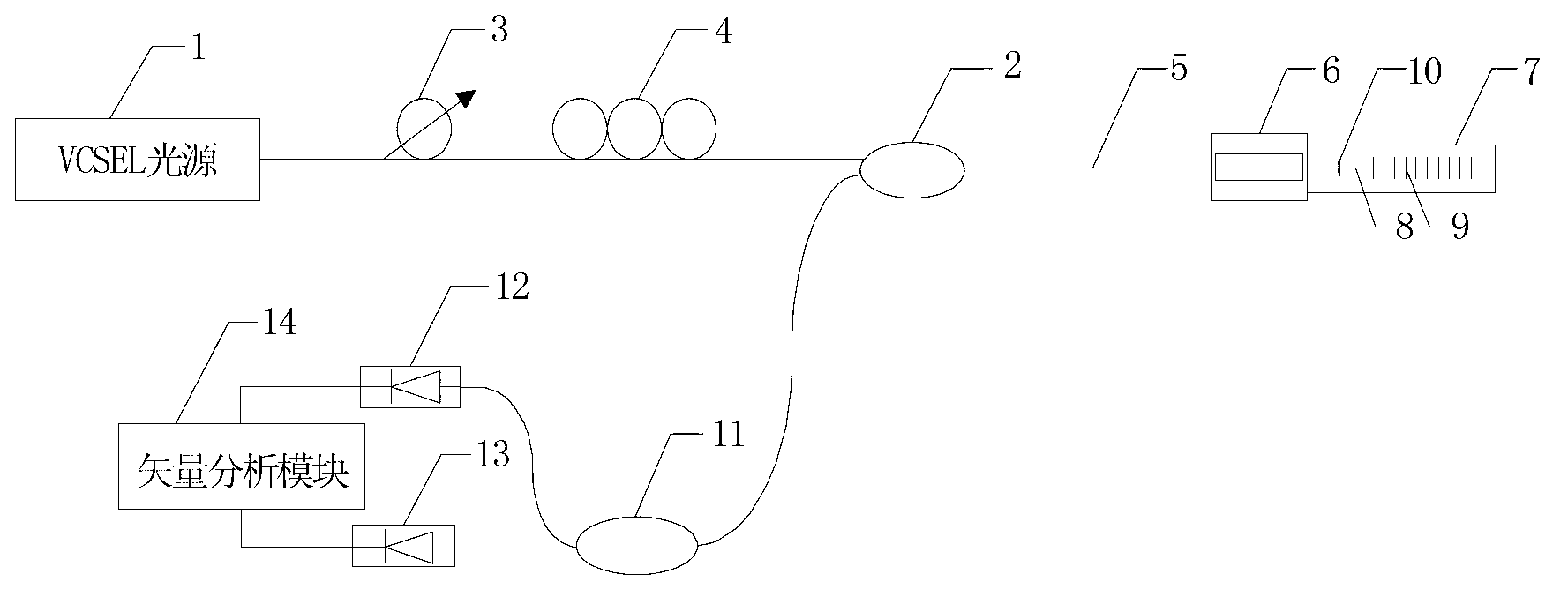

[0045] Such as figure 1 and figure 2 As shown, the twist sensing device of this embodiment includes a VCSEL light source 1, a polarization processing unit, a sensing probe, an orthogonal polarization demodulation processing unit, and a fiber coupler 2. The polarization processing unit, the sensing probe, and an orthogonal polarization The demodulation processing unit is connected through an optical fiber coupler 2;

[0046] The polarization processing unit includes a polarizer 3 and a polarization controller 4, and the VCSEL light source 1, the polarizer 3 and the polarization controller 4 are sequentially connected;

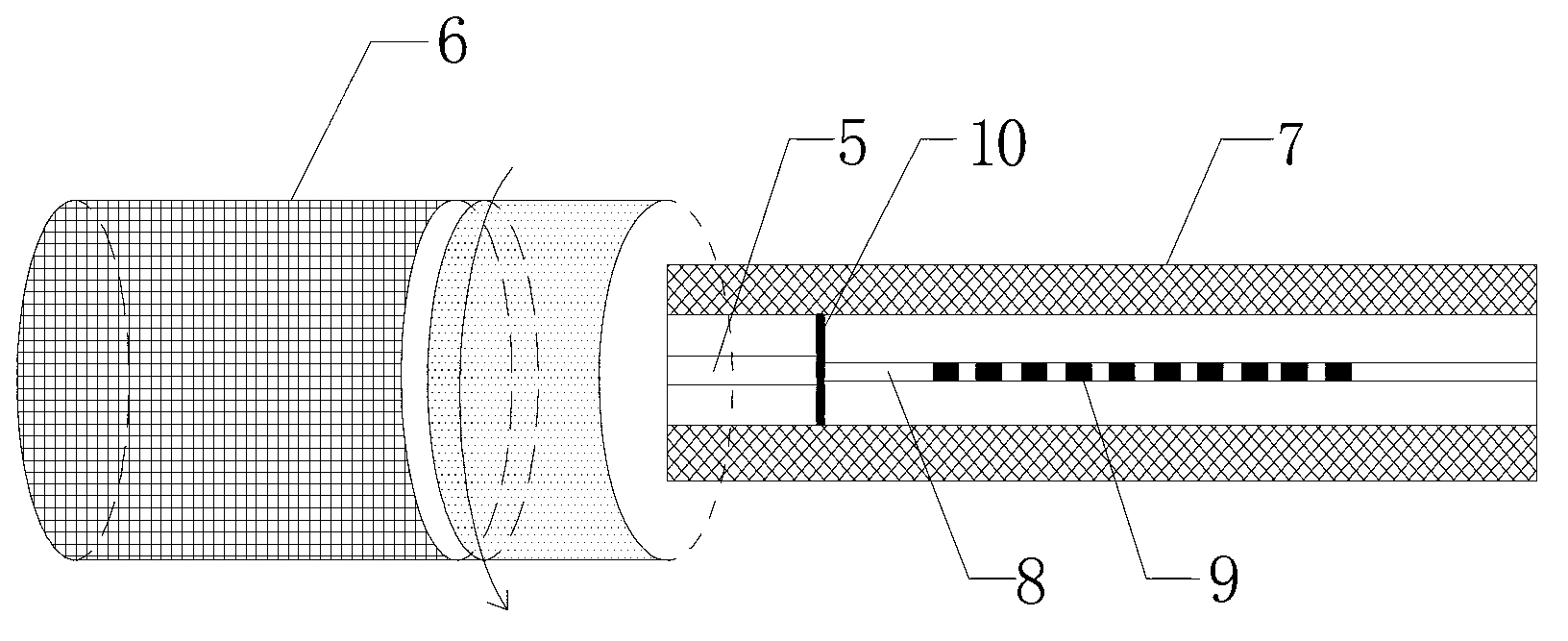

[0047] The sensing probe includes a single-mode fiber 5, a fiber twister 6 and a polarization-maintaining fiber probe 7, and the polarization-maintaining fiber probe 7 includes a polarization-maintaining fiber 8 and a polarization-maintaining fiber grating 9 written in the polarization-maintaining fiber 8, The single-mode fiber 5 and the polarization-maintain...

Embodiment 2

[0058] The torsional sensing device of this embodiment includes a VCSEL light source 1, a polarization processing unit, a sensing probe, an orthogonal polarization demodulation processing unit, and an optical fiber circulator 2, and the polarization processing unit, the sensing probe, and an orthogonal polarization demodulation processing The units are connected through a fiber optic circulator 2. The distance between the fiber twister 6 and the single-mode-polarization-maintaining fiber fusion splicing point 10 is 2mm. The rest of the structure and detection method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com