Device and method for overburden electroplating copper layer on chemical corrosion TSV (through silicon via) surface

A technology of chemical corrosion and electroplating of copper layer, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of excessive copper thickness on the surface, rising costs, raised crystals on the wafer surface, etc., to reduce the burden and reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

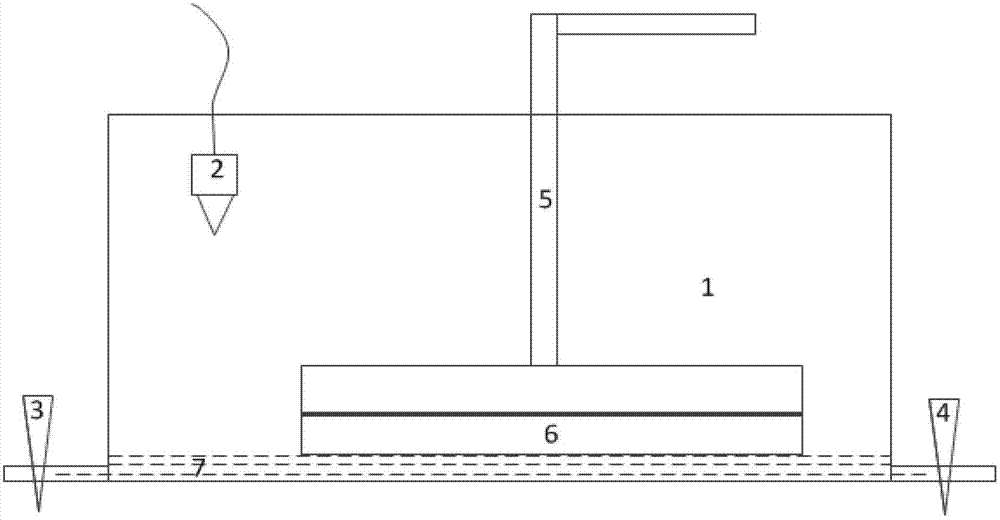

[0011] The main body of the device of the present invention is a simple copper corrosion tank 1, and a ranging sensor 2 is provided on the tank wall (ultrasonic ranging is selected here, and the precision is micron level), which is used to measure the liquid level in the tank. Liquid inlet and outlet, install inlet valve 3 and outlet valve 4 respectively; the wafer after TSV plating is held by an external mechanical arm 5, such as a lever or a mechanical arm, and the surface of the wafer (wafer) 6 is immersed in the copper corrosion tank 1 In the corrosive liquid 7 inside. Its diagram is as follows figure 1 shown. The controllers of the distance measuring sensor 2, the inlet valve 3, the outlet valve 4 and the mechanical arm bar 5 are all connected to a general controller or computer. The corrosion solution can be concentrated nitric acid (concentration 16mol / L-19mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com