Clamp spring type self-locking cable cover on electric connector

An electrical connector and cable cover technology, applied in the field of spring-type self-locking cable cover, can solve the problems of limited application occasions, low reliability of anti-loosening, large space occupation, etc., and achieves high applicability, reduced weight and The effect of volume and space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

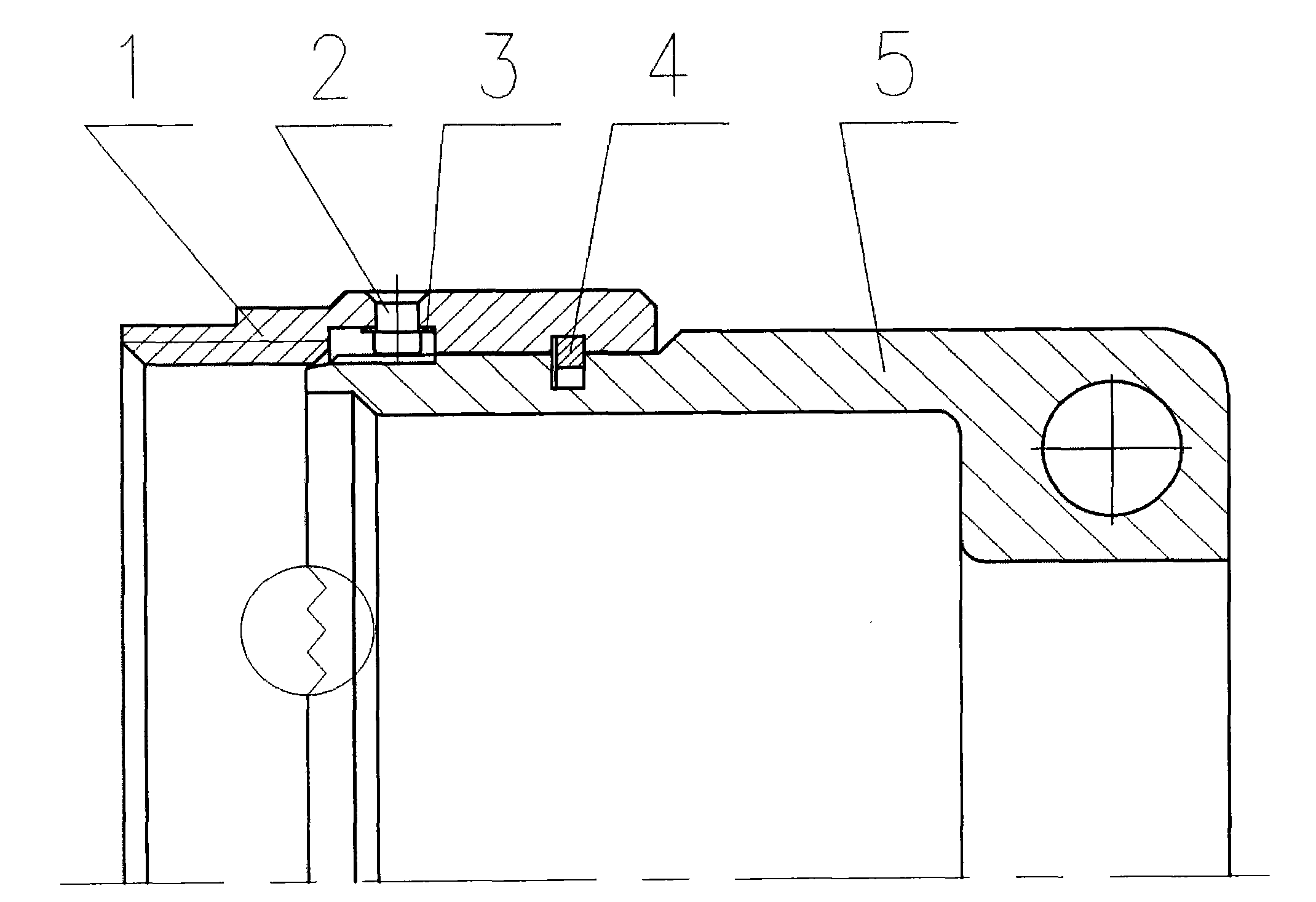

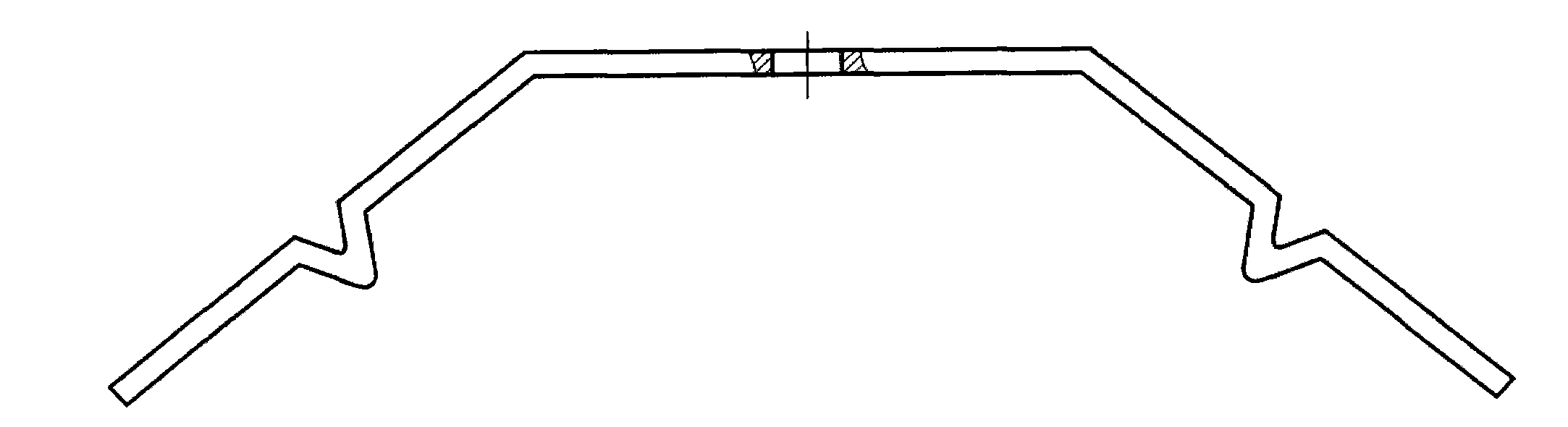

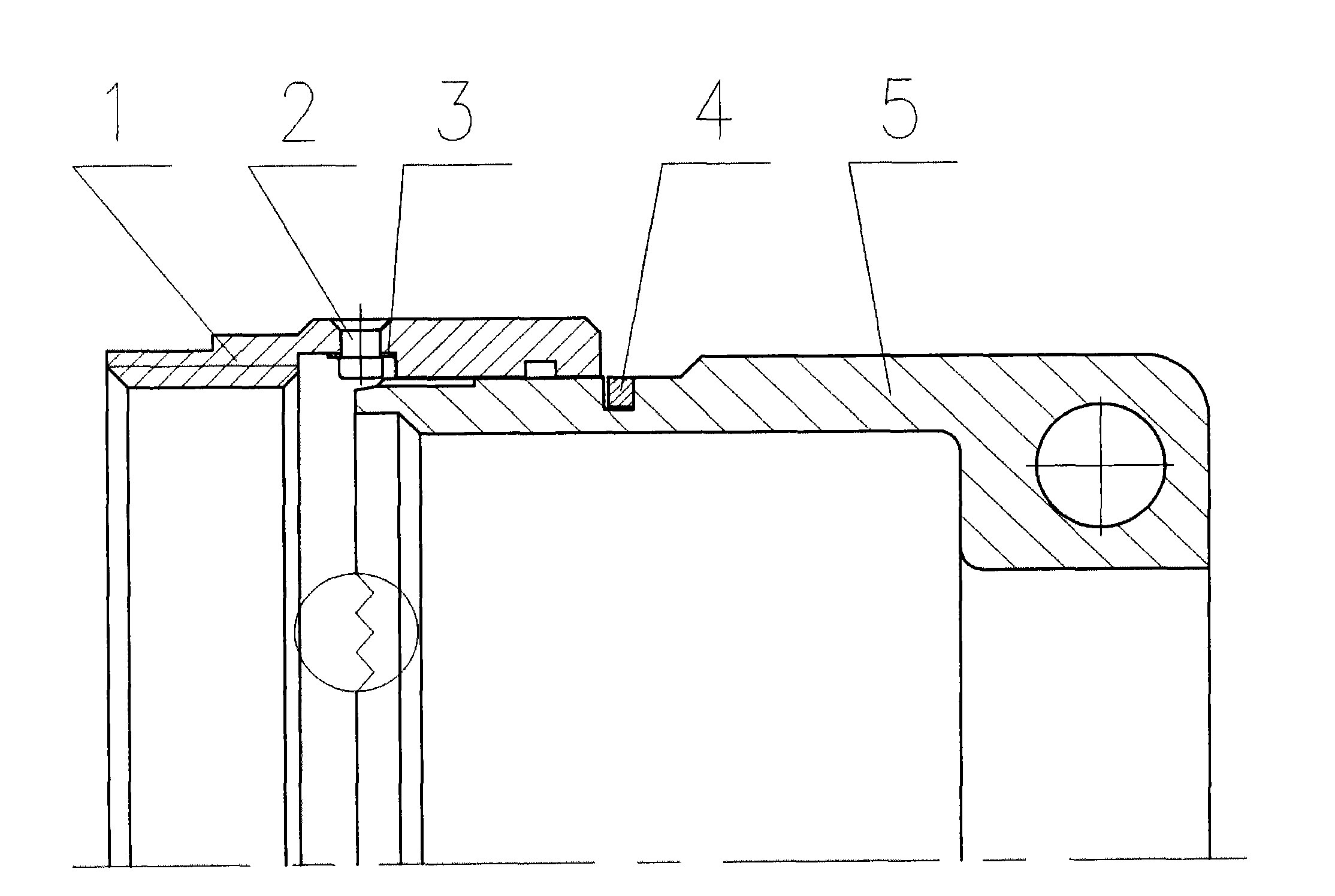

[0020] The circlip type self-locking cable cover of the present invention designs a groove in the connecting nut and a circlip with tines at the same time, and designs convex teeth on the cable cover element to engage with the tines to realize self-locking . The circlip is the key elastic element for anti-loosening and self-locking. It can be made of beryllium bronze, such as QBe2 and C17300. The circlip is fixed in the inner groove of the connecting nut by means of bayonet riveting, and the connecting nut is connected with the clamping ring. The cable cover elements are fixed together, and only a normal fit gap needs to be reserved between the connection nut and the cable cover element, and the connection nut can rotate freely relative to the cable cover element.

[0021] Such as figure 1 As shown, the embodiment of the circlip type self-locking cable cover of the present invention includes a connection nut 1, a bayonet pin 2, a clip spring 3, a clip ring 4 and a cable cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com