Heat memory method after power failure of converter with heat radiator

A technology of thermal memory and heat sink, applied in the field of thermal memory, can solve problems such as high cost, reduced system reliability, complex circuit, etc., and achieve low cost, easy implementation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

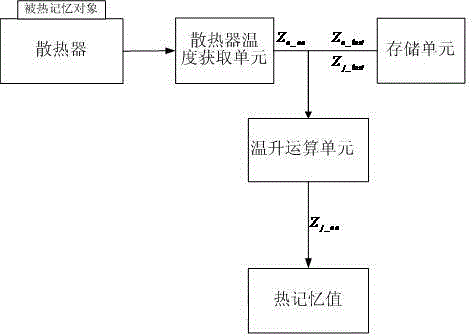

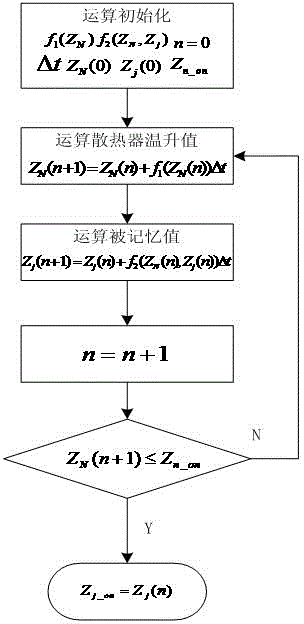

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

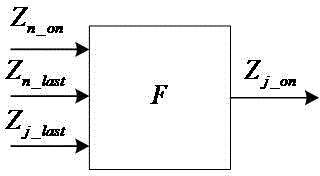

[0021] Such as figure 2 and image 3 As shown, the present invention has designed a kind of thermal memory method after the converter with radiator loses power, comprises following concrete steps:

[0022] Step (1): The converter reads the thermal memory value Z of the object to be thermally memorized when it was powered off last time from the storage unit j_lat and the temperature rise value of the radiator at the last power-off time Z n_lat , when the converter is powered on this time, the temperature of the heat sink is measured as T S and the ambient temperature is T 0 , using the formula Z n_on =k(T S -T O ) to obtain the temperature rise value of the radiator that is powered on this time Z n_on , where k is defined as a correction coefficient;

[0023] Step (2): Using the Differential Equation of State ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com