External circulation heating regeneration gas dryer with three-way valves

A technology of heating regeneration and gas drying, applied in chemical instruments and methods, combined devices, dispersed particle separation, etc., can solve the problems of rising dew point temperature of outlet compressed gas, unachievable drying results, loss of adsorption capacity, etc. The effect of less, high equipment efficiency, easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

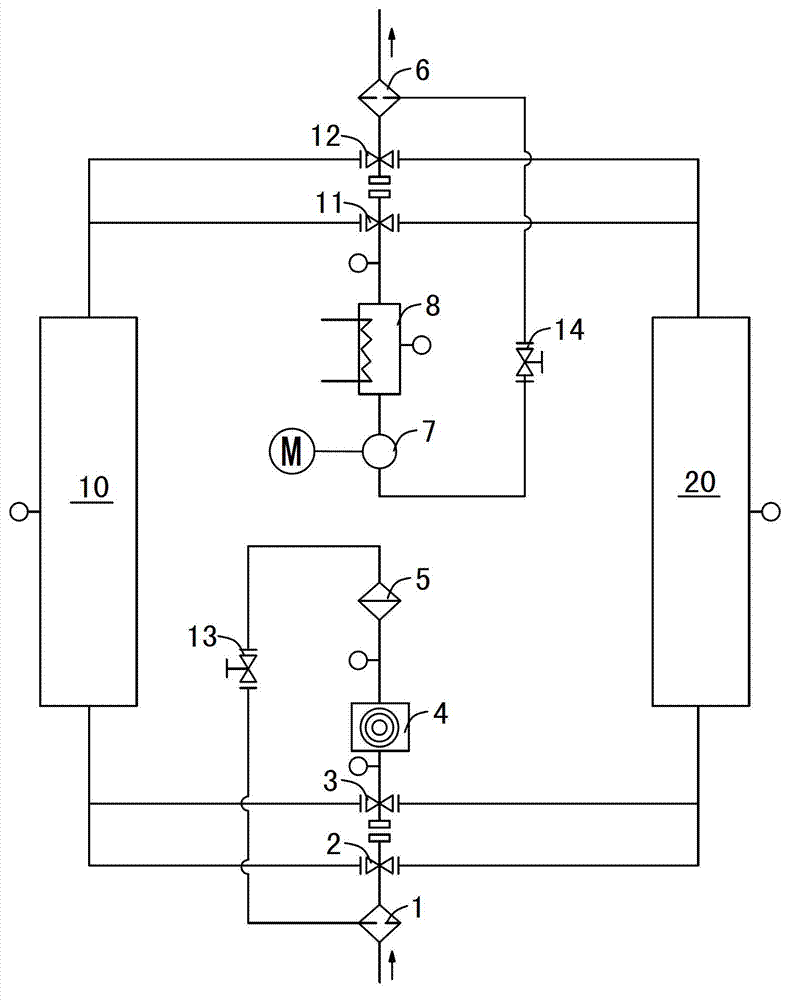

[0015] a kind of like figure 1 The shown three-way valve external circulation heating regenerative gas dryer includes first and second adsorption / regeneration towers 10, 20, a pre-filter 1, and a post-filter 6. In the first and second adsorption / regeneration towers 10 The inlets of , 20 are respectively communicated with the two-way ports of the three-way valve A2 through the inlet pipe, and the third way port of the three-way valve A2 is communicated with the outlet of the pre-filter 1 through the pipeline; The outlets of the regeneration towers 10 and 20 are respectively communicated with the two-way ports of the three-way valve B12 through the outlet pipe, and the third port of the three-way valve B12 is communicated with the inlet of the post-filter 6 through a pipeline, wherein, in A three-way valve C11 is connected with the three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com