Catalyst for preparing styrene through ethylbenzene dehydrogenation and preparation method of catalyst

An ethylbenzene dehydrogenation production and catalyst technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of insufficient catalyst utilization and low catalyst reaction activity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

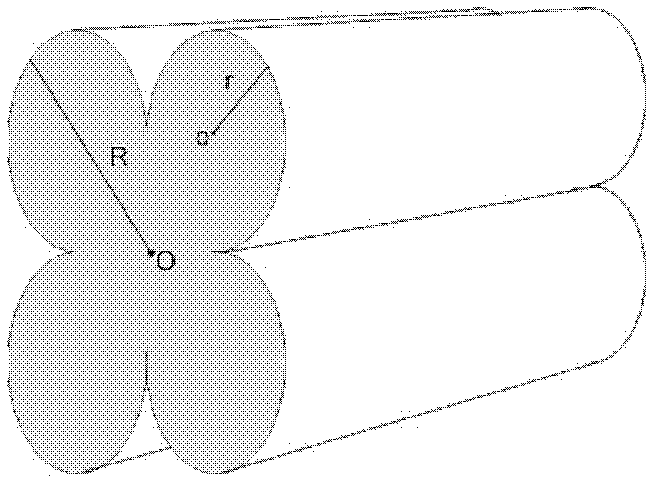

Image

Examples

Embodiment 1~9

[0032] The physical properties of the catalyst prepared by extruding, pelletizing, drying, and roasting the wet-kneaded paste block prepared by the same components and the same method as in the comparative example are shown in Table 1 :

[0033] Table 1 The physical properties of the four-leaf catalyst

[0034]

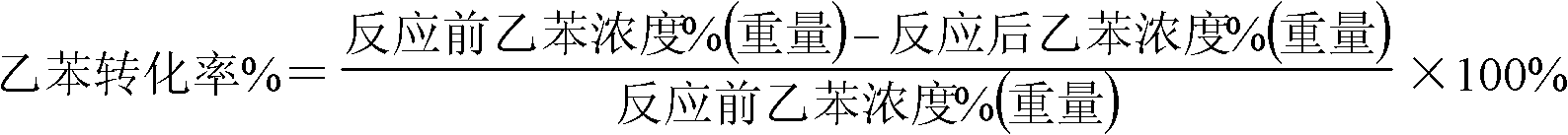

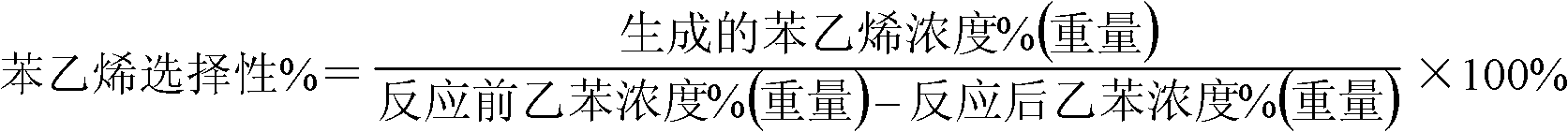

[0035] Respectively with comparative example in table 2, embodiment catalyst take pure ethylbenzene as raw material ethylbenzene dehydrogenation styrene performance see table 2:

[0036] Table 2 Catalyst ethylbenzene dehydrogenation performance comparison *

[0037]

[0038] * : Catalyst performance is the average value of 200 hours after the reaction is stable.

[0039] Select several embodiment, the life-span of the ethylbenzene dehydrogenation styrene reaction of comparative example catalyst is shown in Table 3:

[0040] Table 3 The performance comparison of different embodiment catalysts represented by styrene per pass yield in the ethylbenzene dehydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com