Preparation method of CuSn10Bi3.5 copper-bismuth alloy powder

A powder preparation and alloy powder technology, which is applied in the field of CuSn10Bi3.5 copper-bismuth alloy powder preparation, can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

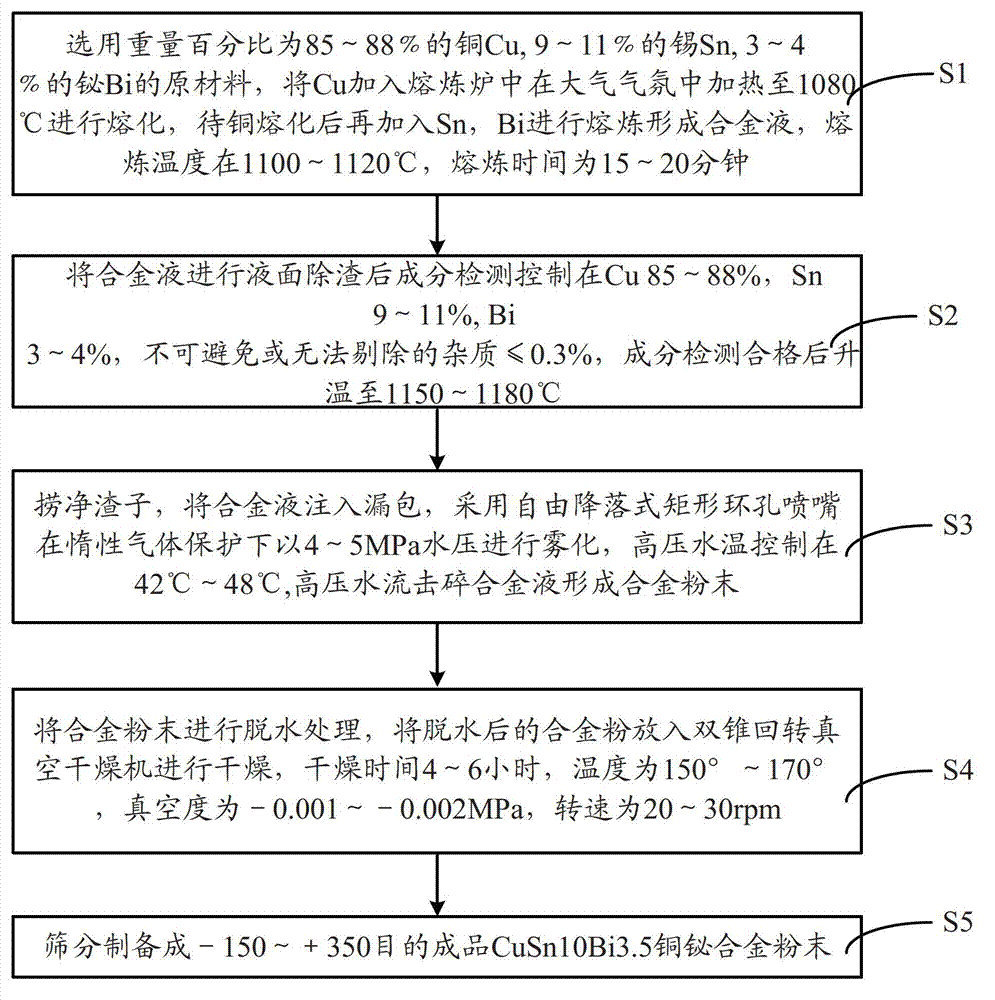

[0018] refer to figure 1 , shows the flow chart of the steps of the CuSn10Bi3.5 copper-bismuth alloy powder preparation method of the embodiment of the present invention, which includes the following steps:

[0019] S1, select copper Cu with a weight percentage of 85-88%, 9-11% tin Sn, and 3-4% bismuth Bi as raw materials, add Cu to a smelting furnace and heat to 1080°C in the atmosphere for melting, and wait After the copper is melted, Sn is added, and Bi is smelted to form an alloy liquid. The smelting temperature is 1100-1120°C, and the smelting time is 15-20 minutes;

[0020] S2. After removing slag on the liquid surface, the composition detection of the alloy liquid is controlled at Cu85-88%, Sn9-11%, Bi3-4%, and the inevitable or unremovable impurities are ≤0.3%. After the composition test is qualified, the temperature is raised to 1150-1180 ℃;

[0021] S3, remove the slag, inject the alloy liquid into the leakage bag, use the free-falling rectangular ring hole nozzle ...

Embodiment 1

[0027] A method for preparing CuSn10Bi3.5 copper-bismuth alloy powder, comprising the following steps:

[0028] (1) Select the raw material weight percentage components as follows: 1# electrolytic copper 86.5%, 1# tin ingot 10%, 99.95# bismuth ingot 3.5%, specifically adopt 0.25T intermediate frequency smelting furnace, take 1# electrolytic copper 216.25Kg, 1# tin ingot 25Kg, 99.95# bismuth ingot 8.75Kg, first add Cu and heat to 1080°C in the atmosphere for melting, then add Sn and Bi for melting to obtain alloy liquid after Cu is melted, the melting temperature is 1100-1120°C, The melting time is 15-20 minutes.

[0029] (2) After the slag removal on the liquid surface of the alloy liquid, the composition detection is controlled at Cu85-88%, Sn9-11%, Bi3-4%, and the inevitable or unremovable impurities are ≤0.3%, and the temperature is raised to 1150-1180 after passing the composition detection ℃.

[0030] (3) Remove the slag, inject the alloy liquid into the leakage bag, an...

Embodiment 2

[0035] A preparation method of CuSn10Bi3.5 copper-bismuth alloy powder, which comprises the following steps:

[0036] (1) The weight percentage of raw materials is selected as follows: 1# electrolytic copper 85%, 1# tin ingot 11%, 99.95# bismuth ingot 4%, the raw material Cu is added to the smelting furnace and heated to 1080 ° C in the atmosphere for melting. After Cu is melted, Sn and Bi are added for smelting, the smelting temperature is 1100-1120°C, and the smelting time is 15-20 minutes.

[0037] (2) After removing slag from the alloy liquid surface, the composition detection is controlled at Cu85-88%, Sn9-11%, Bi3-4%, and the unavoidable or unremovable impurities are ≤0.3%. .

[0038] (3) Remove the slag, inject the alloy liquid into the leakage bag, and use the free-falling rectangular ring hole nozzle to atomize with 4MPa water pressure under the protection of inert gas. The high-pressure water temperature is controlled at 48°C, and the high-pressure water flow crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap