Small-modulus spiral bevel gear cutter

A technology of spiral bevel gear and small modulus, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., and can solve problems such as high mechanical manufacturing costs, increased cost of milling cutters, and poor results , to achieve cost saving, simple and convenient use, ingenious and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

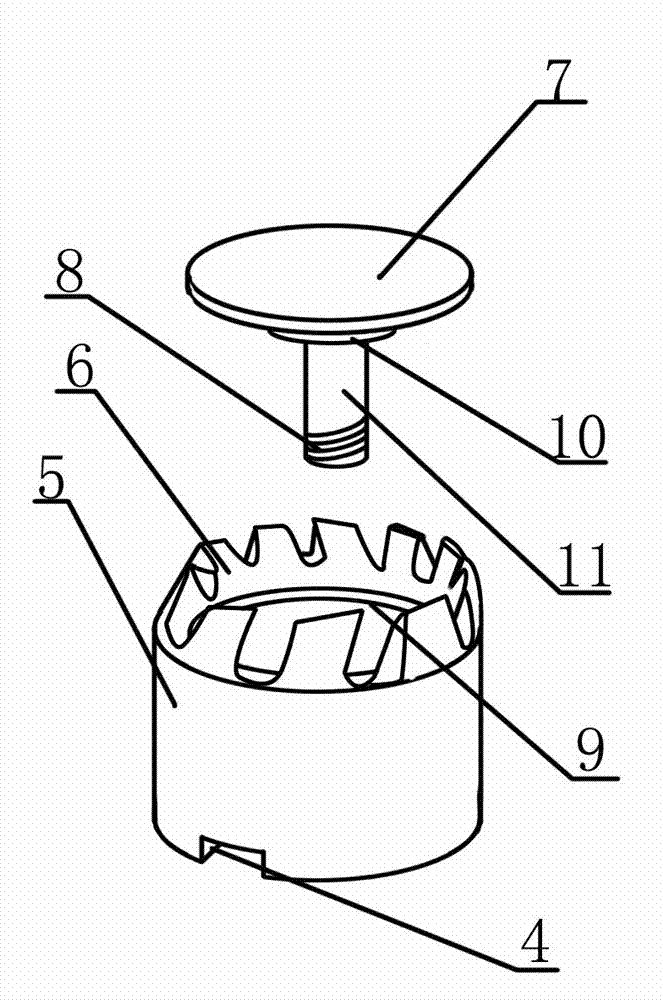

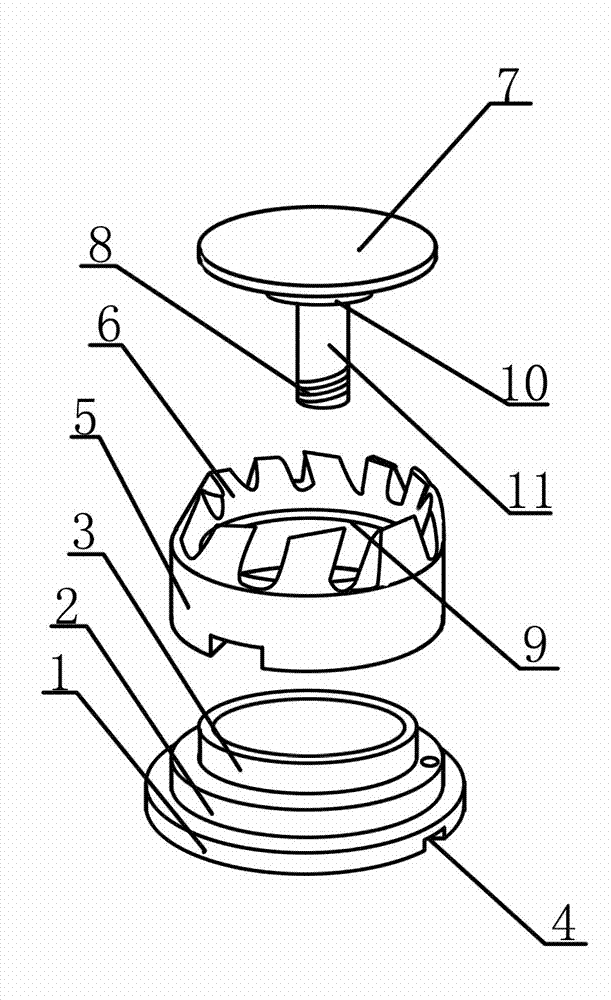

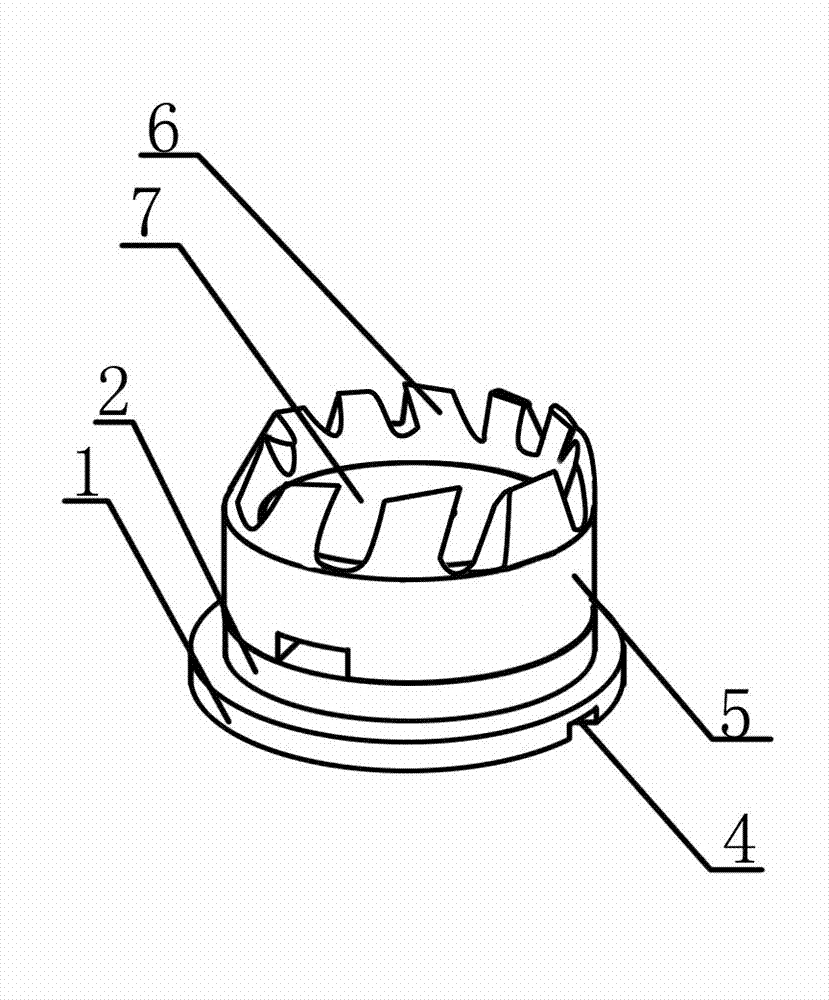

[0018] like figure 1 As shown, a new type of small modulus spiral bevel gear milling cutter is provided, and the cutter body 5 is improved. A small modulus spiral bevel gear milling cutter includes a cutter body 5, a connecting rod 11, and the cutter body 5 is in the shape of a round tube, the cutter body 5 is made of high-speed steel, one end of the cutter body 5 is provided with a blade 6, the inner wall of the cutter body 5 is provided with a diameter-reducing step 9 near the blade 6, and the connecting rod One end of 11 is provided with thread 8, and the other end is provided with connecting seat 7, and described connecting seat 7 is circular, and described connecting seat 7 is provided with circular protrusion 10 near connecting rod 11, and described circular protrusion 10 Equivalent to the role of a gasket, it plays a better connection and fixing role. The connecting seat 7 is compatible with the diameter-reducing step 9, and the other end of the cutter body 5 is connect...

Embodiment 2

[0020] like figure 1 As shown, a new type of small modulus spiral bevel gear milling cutter is provided, and the cutter body 5 is improved. A small modulus spiral bevel gear milling cutter includes a cutter body 5, a connecting rod 11, and the cutter body 5 is in the shape of a round tube, the cutter body 5 is made of high-speed steel, one end of the cutter body 5 is provided with a blade 6, the inner wall of the cutter body 5 is provided with a diameter-reducing step 9 near the blade 6, and the connecting rod One end of 11 is provided with thread 8, and the other end is provided with connecting seat 7, and described connecting seat 7 is circular, and described connecting seat 7 is provided with circular protrusion 10 near connecting rod 11, and described circular protrusion 10 Equivalent to the role of a gasket, it plays a better connection and fixing role. The connecting seat 7 is compatible with the diameter-reducing step 9, and the other end of the cutter body 5 is connect...

Embodiment 3

[0022] like figure 1 As shown, a new type of small modulus spiral bevel gear milling cutter is provided, and the cutter body 5 is improved. A small modulus spiral bevel gear milling cutter includes a cutter body 5, a connecting rod 11, and the cutter body 5 is in the shape of a round tube, the cutter body 5 is made of high-speed steel, one end of the cutter body 5 is provided with a blade 6, the inner wall of the cutter body 5 is provided with a diameter-reducing step 9 near the blade 6, and the connecting rod One end of 11 is provided with thread 8, and the other end is provided with connecting seat 7, and described connecting seat 7 is circular, and described connecting seat 7 is provided with circular protrusion 10 near connecting rod 11, and described circular protrusion 10 Equivalent to the role of a gasket, it plays a better connection and fixing role. The connecting seat 7 is compatible with the diameter-reducing step 9, and the other end of the cutter body 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com