Testing system for submersible motor in high-temperature and high-pressure environment

A technology of submersible motor and test system, which is applied in the direction of motor generator testing, etc., can solve the problems of expensive operation costs, waste of manpower, material resources and financial resources, etc., and achieve the effect of reasonable and practical structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

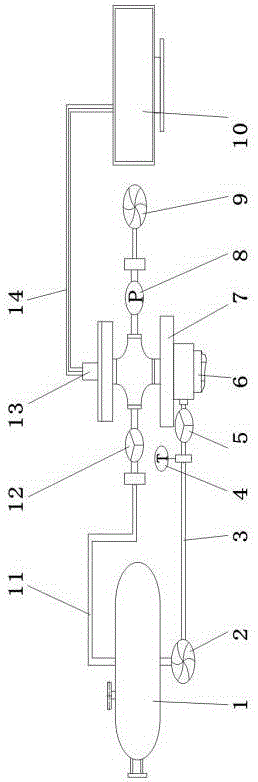

[0007] Embodiment 1: Lower the submersible motor 13 into the test well, install and seal the high-pressure special test wellhead assembly 7, connect the power supply and the signal transmission cable 14, inject an appropriate amount of test oil into the high-pressure heating tank 1, and feed the test oil after closing the valve. After the test oil is heated to a specified temperature, the first high-pressure valve 5 and the second high-pressure valve 12 are opened, the high-temperature test oil is injected into the test well casing 6 through the first high-pressure pipeline 3, and the high-pressure pipeline pump 2 is turned on to allow the test oil to The high-pressure oil tank 1, the first high-pressure pipeline 3, the second high-pressure pipeline 11 and the test well casing 6 are circulated, and the thermometer 4 is observed to keep the test oil temperature at the specified test temperature, and the booster pump 9 is turned on. Pressurize the test well, observe the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com