a receiving antenna

A technology for receiving antenna and antenna, which is applied in the direction of antenna, antenna grounding switch structure connection, radiation unit cover, etc., can solve the problems of affecting the verticality of the inner conductor, increasing the processing difficulty, aggravating the deformation problem, etc., and achieving the processing and assembly efficiency and cost. The effect of improving, avoiding the problem of machining error and avoiding the problem of assembly error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

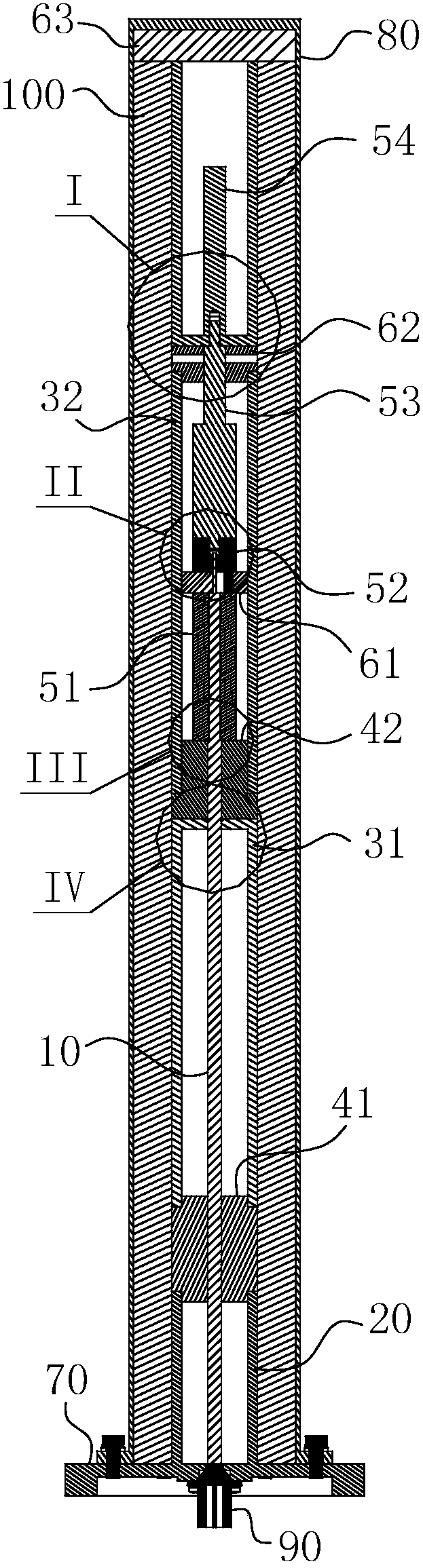

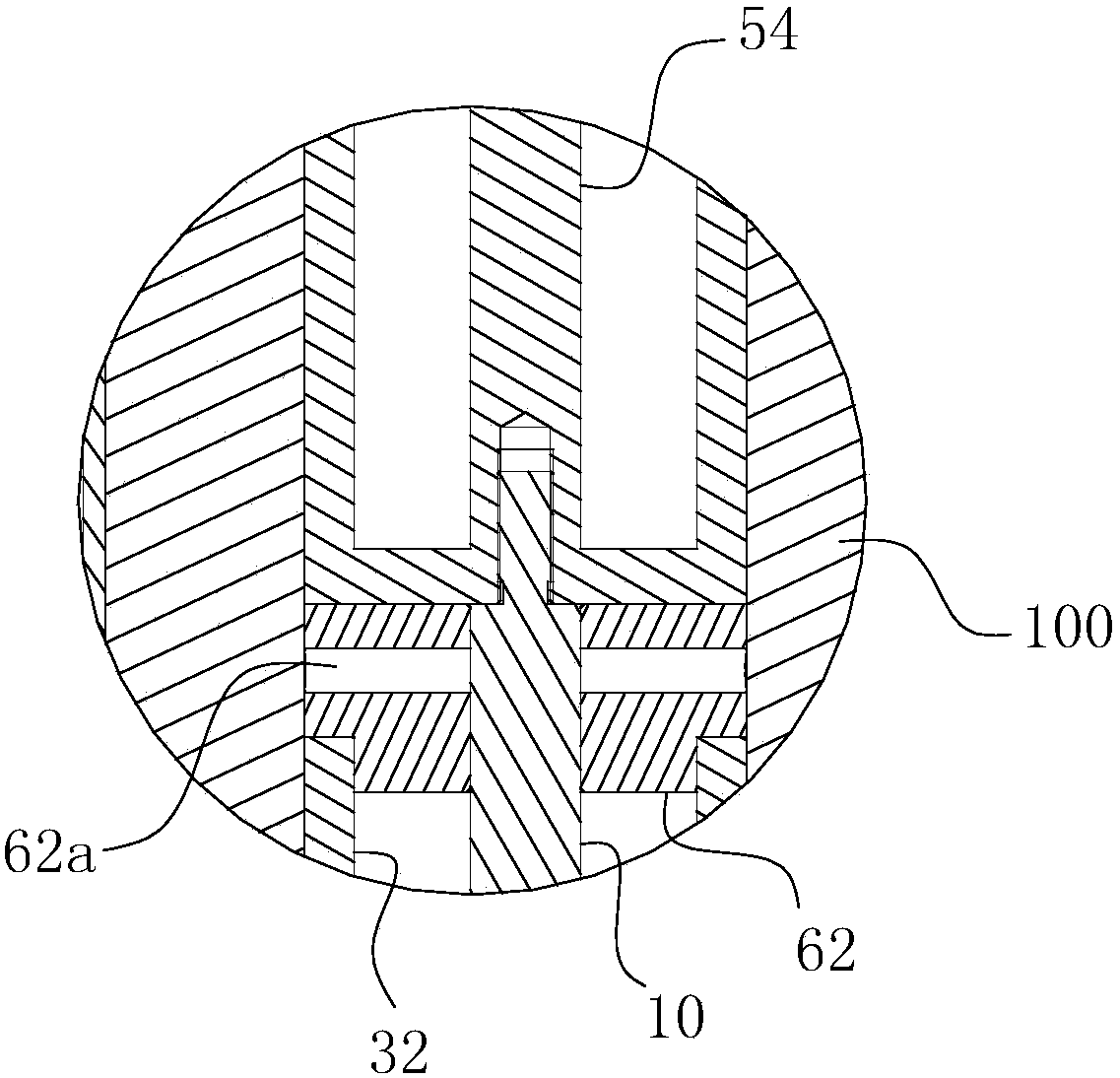

[0038] For ease of understanding, combined here Figure 1-9 Concrete structure of the present invention and course of work are described further as follows:

[0039] The concrete structure of the present invention is as Figure 1-2 and Figure 7-8 As shown, it includes an antenna module, a foam support 100 and a radome 80 from inside to outside. Wherein, the opening of the radome 80 is fixedly connected to the installation base 70 , so that the cavity enclosed by the two constitutes an accommodating cavity for accommodating the antenna module and the foam support 100 . The foam support 100 serves to fill the fit gap between the antenna module and the radome 80 to ensure the structural stability of the antenna module after assembly.

[0040] As far as the antenna module is concerned, the details are as follows: Figure 1-6 When the structure is shown, it includes a radio frequency coaxial semi-rigid cable 10 with an N-type connector, a reflector 20, two outer conductors, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com