Exhaust bag and manufacture method thereof

An exhaust port and exhaust side technology, applied in the field of exhaust bags, can solve the problems of returning to the bag air, complicated manufacturing process of the exhaust bag, and inability to reuse, etc., and achieve the effect of preventing air reverse osmosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

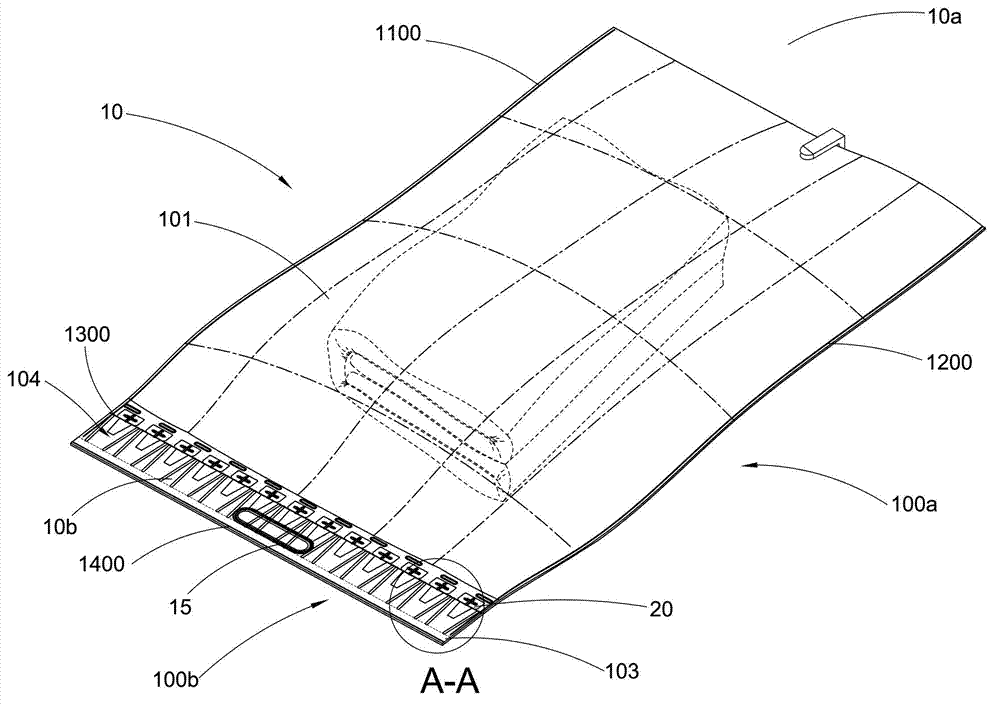

[0059] Such as Figure 1 to Figure 5 As shown, the vent bag according to a preferred embodiment of the present invention includes a bag body 10, the bag body 10 forms a storage space 101 that can accommodate items and at least one sealable opening 102 formed on the bag body 10 , for placing items into the accommodating space 101 . That is to say, through the opening 102 , the accommodating space 101 of the bag body 10 can communicate with the outside. The opening 102 is sealed after the items to be stored or transported are placed in the accommodation space 101 of the bag body 10 , so as to prevent outside air from entering the accommodation space 101 again.

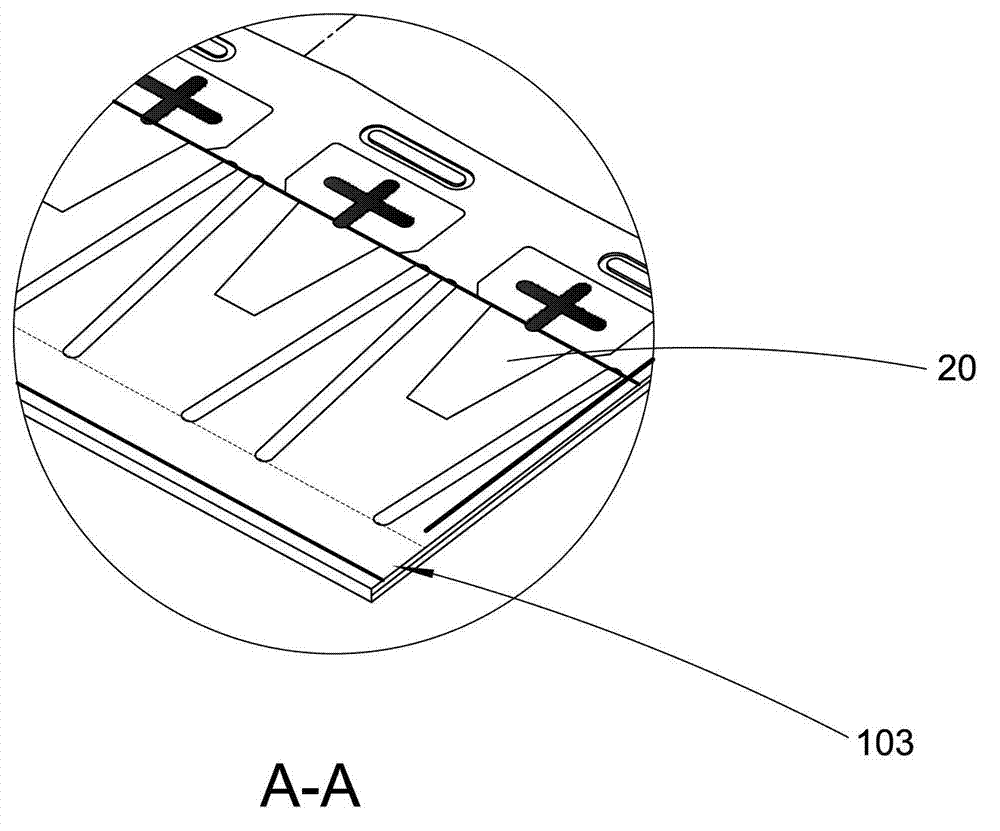

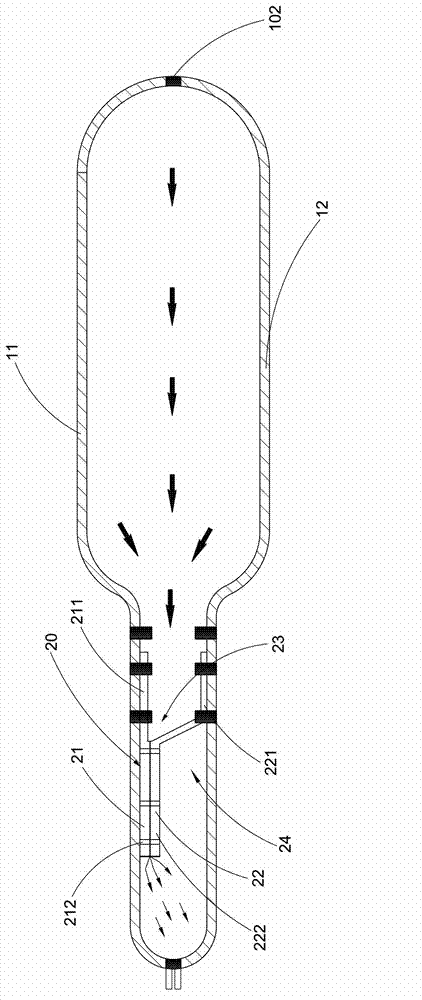

[0060] The degassing bag further includes at least one one-way check valve 20. According to this preferred embodiment, the one-way check valve 20 can be arranged on the edge of the bag body 10 for closing the accommodating space 101 The air inside is discharged out of the bag body 10 . Specifically, after the article ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com