Aquarium filtering material with high porosity and preparation method thereof

A filter material and high porosity technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of ornamental fish's immune decline, easy death, easy deterioration of aquarium water quality, etc., and achieve a strong culture ratio Surface area, improve immunity, and maintain the effect of continuous and healthy growth of organisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

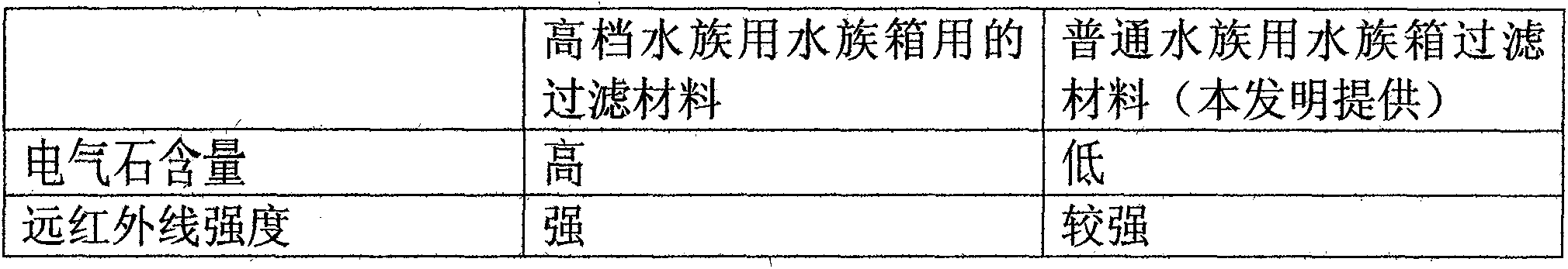

Image

Examples

Embodiment 1

[0045] Embodiment one, have the aquarium filter material with high porosity, wherein: comprise 1 part of tourmaline, 12 parts of diatomaceous earth, 57 parts of magnesium clay, 10 parts of albite powder, 5 parts of quartz powder, 15 parts of bamboo charcoal powder; Wherein the tourmaline is magnesium tourmaline or black tourmaline; wherein the magnesia clay is SiO by weight ratio 2 55.64%, Al 2 o 3 6.82%, Fe 2 o 3 1.05%, CaO4.71%, MgO20.35%, TiO 2 0.42%, K 2 O1.10%, Na 2 O0.35%, LOI9.56%;

[0046] Preparation Process:

[0047] (1) mixing ingredients, extruding, drying,

[0048] (2) uniformly heat up from room temperature to 1080°C, and the uniform temperature rise time is 10 hours;

[0049] (3) heat preservation at 1080°C for 1 hour;

[0050] (4) then uniformly cool down to 1050°C, and the uniform cooling time is 2 hours;

[0051] (5) The temperature is evenly raised from 1050°C to 1080°C, and the average heating time is 1 hour;

[0052] (6) heat preservation at 1080...

Embodiment 2

[0055] Embodiment two, the aquarium filter material with high porosity, wherein: comprise 1 part of tourmaline, 12 parts of diatomaceous earth, 42 parts of magnesium clay, 10 parts of albite powder, 20 parts of quartz powder, 15 parts of bamboo charcoal powder; Wherein the tourmaline is magnesium tourmaline or black tourmaline; wherein the magnesia clay is SiO by weight ratio 2 55.64%, Al 2 o 3 6.82%, Fe 2 o 3 1.05%, CaO4.71%, MgO20.35%, TiO 2 0.42%, K 2 O1.10%, Na 2 O0.35%, LOI9.56%;

[0056] Preparation Process:

[0057] (1) mixing ingredients, extruding, drying,

[0058] (2) uniformly heat up from room temperature to 1080°C, and the uniform temperature rise time is 10 hours;

[0059] (3) heat preservation at 1080°C for 1 hour;

[0060] (4) then uniformly cool down to 1050°C, and the uniform cooling time is 2 hours;

[0061] (5) The temperature is evenly raised from 1050°C to 1080°C, and the average heating time is 1 hour;

[0062] (6) heat preservation at 1080°C...

Embodiment 3

[0065] Embodiment three, have the aquarium filter material of high porosity, wherein: comprise 1 part of tourmaline, 12 parts of diatomaceous earth, 57 parts of magnesia clays, 10 parts of albite powders, 12 parts of quartz powders, 8 parts of bamboo charcoal powders; Wherein the tourmaline is magnesium tourmaline or black tourmaline; wherein the magnesia clay is SiO by weight ratio 2 55.64%, Al 2 o 3 6.82%, Fe 2 o 3 1.05%, CaO4.71%, MgO20.35%, TiO 2 0.42%, K 2 O1.10%, Na 2 O0.35%, LOI9.56%;

[0066] Preparation Process:

[0067] (1) mixing ingredients, extruding, drying,

[0068] (2) uniformly heat up from room temperature to 1080°C, and the uniform temperature rise time is 10 hours;

[0069] (3) heat preservation at 1080°C for 1 hour;

[0070] (4) then uniformly cool down to 1050°C, and the uniform cooling time is 2 hours;

[0071] (5) The temperature is evenly raised from 1050°C to 1080°C, and the average heating time is 1 hour;

[0072] (6) heat preservation at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com