Reactive dye constant-temperature dip dyeing method

A technology of reactive dyes and dip dyeing, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor color stability, large energy consumption, and unstable dyeing temperature range, etc., and achieve the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

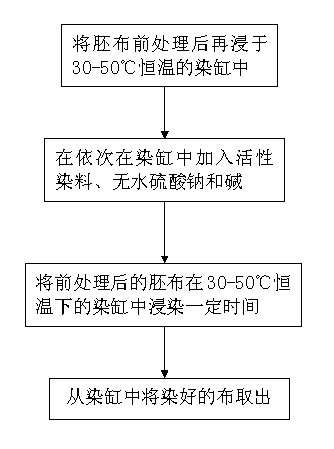

Image

Examples

Embodiment 1

[0021] After pretreatment, the gray cloth is immersed in a dyeing vat at a constant temperature of 35°C, and then sequentially added to the dyeing vat are reactive dyes containing water-soluble groups that can dissolve in water at low temperatures, anhydrous sodium sulfate and alkali. The gray cloth is soaked in a dyeing vat at a constant temperature of 35°C for a certain period of time, and then the dyed cloth is taken out from the dyeing vat.

Embodiment 2

[0023] After pretreatment, the gray cloth is immersed in a dyeing vat at a constant temperature of 30°C, and then sequentially added to the dyeing vat are reactive dyes containing water-soluble groups that can dissolve in water at low temperatures, anhydrous sodium sulfate and alkali, and the pretreated The gray cloth is soaked in a dyeing vat at a constant temperature of 30°C for a certain period of time, and then the dyed cloth is taken out from the dyeing vat.

Embodiment 3

[0025] After pretreatment, the gray cloth is immersed in a dyeing vat at a constant temperature of 50°C, and then sequentially added to the dyeing vat are reactive dyes containing water-soluble groups that can be dissolved in water at low temperatures, anhydrous sodium sulfate and alkali. The gray cloth is soaked in a dyeing vat at a constant temperature of 50°C for a certain period of time, and then the dyed cloth is taken out from the dyeing vat.

[0026] A constant-temperature dip-dyeing method of active dyes in the present invention, the gray cloth is pre-treated and then dip-dyeed in a low-temperature dyeing vat, replacing the dip-dyeing in a high-temperature dyeing vat at 60-80°C in the original process, and improving the original effect on the basis of achieving the original effect. color stability. Further calculation from the cost: Compared with the traditional process, the constant temperature dip dyeing method of reactive dyes in the present invention reduces the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com