Method for quickly building road on new reclamation sludge foundation

A technology for filling silt and foundation, which is applied in the field of foundation treatment, can solve the problems of reducing the reinforcement effect of heap load preloading, weakening the water permeability of the sand cushion, and large compression deformation of the foundation, so as to improve the reinforcement effect, reduce post-construction settlement, Post-maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is implemented according to the following steps:

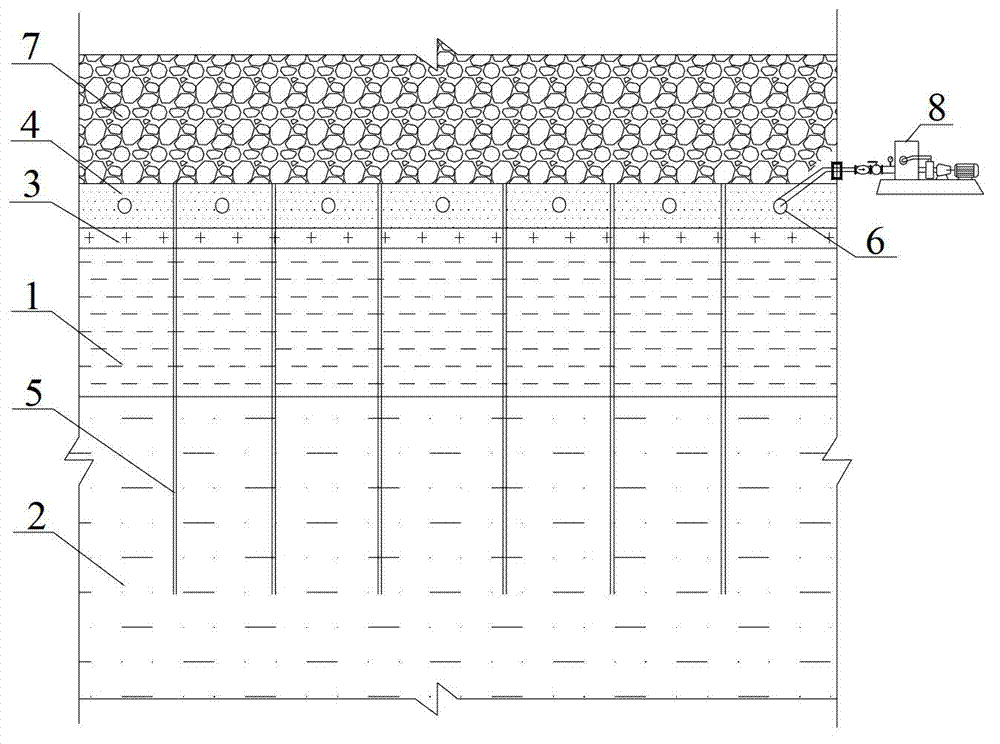

[0031] (1) Build a cofferdam, and fill the silt 1 on the original soft soil 2 .

[0032] (2) Set the working layer 3 on the surface of the dredging silt 1, lay a layer of woven cloth first, and then lay a layer of geogrid; A layer of woven cloth forms a working layer 3 with a certain bearing capacity.

[0033] (3) Lay the sand cushion 4 on the working layer 3, and the thickness of the sand cushion shall meet the requirements of relevant specifications.

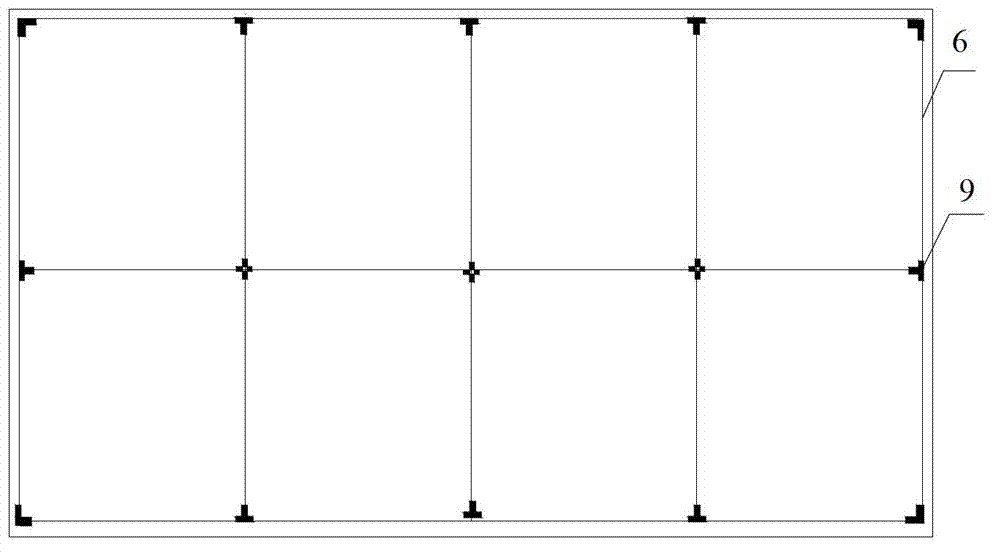

[0034] (4) Insert the vertical drainage body 5 on the sand cushion layer 4 . The vertical drainage bodies are arranged at certain intervals (0.8~1.0m), and the connection lines on the plane form a square or triangle.

[0035] (5) Set vertical and horizontal drainage pipelines 6 on the sand cushion, bury 20~25cm in the sand cushion, cover with sand, and level the site. Horizontal drainage channels must be wrapped with non-woven geotextiles and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com