A Repair Method for Settling Ballastless Track

A repair method and ballastless track technology, which is applied in track, track laying, track maintenance, etc., can solve the problems of small lifting force, low lifting speed, and poor lifting accuracy, and achieve convenient construction, light and handy equipment, and realization of repair work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

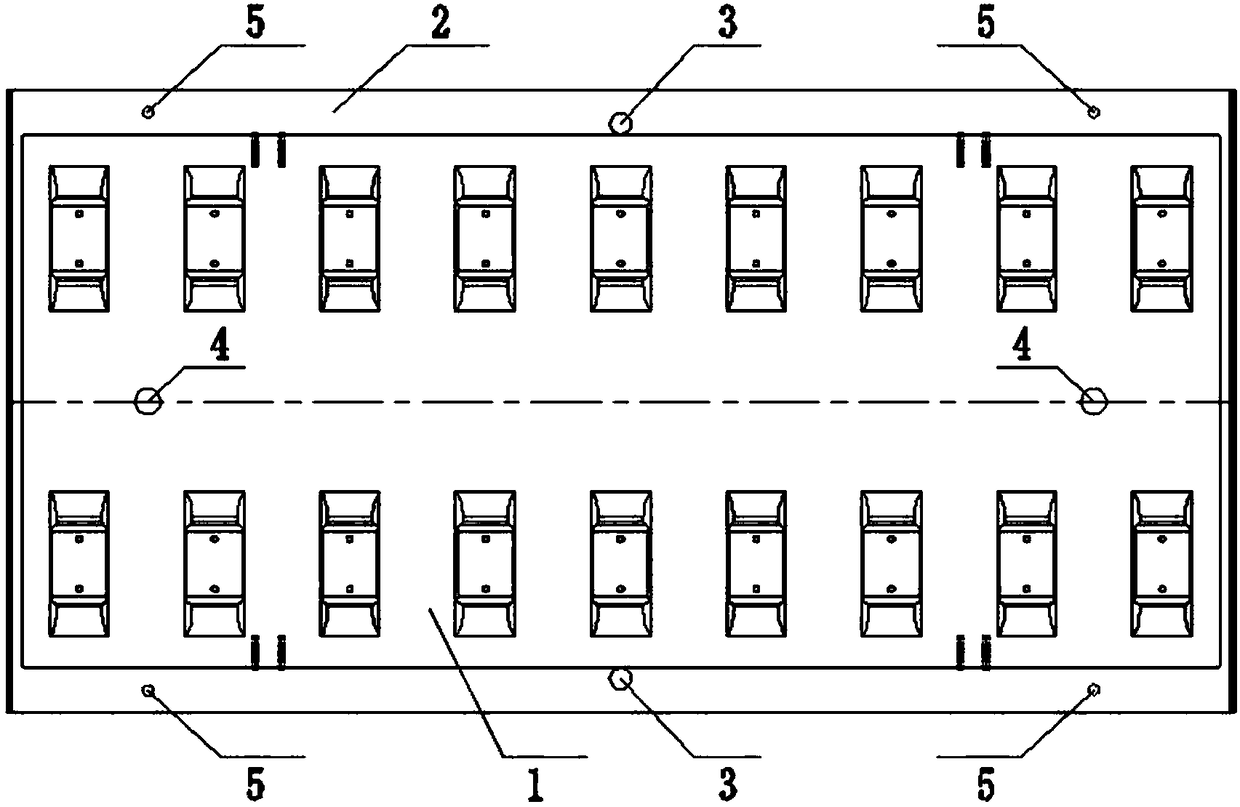

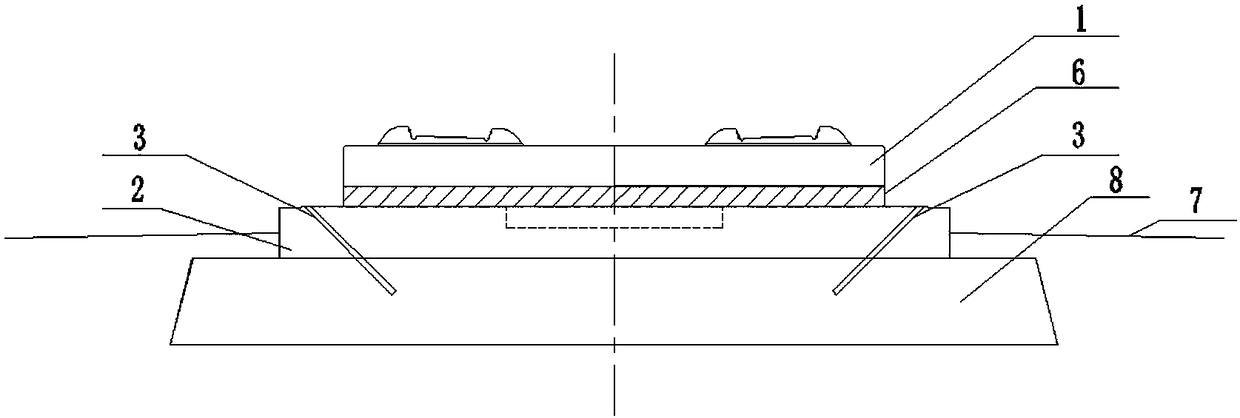

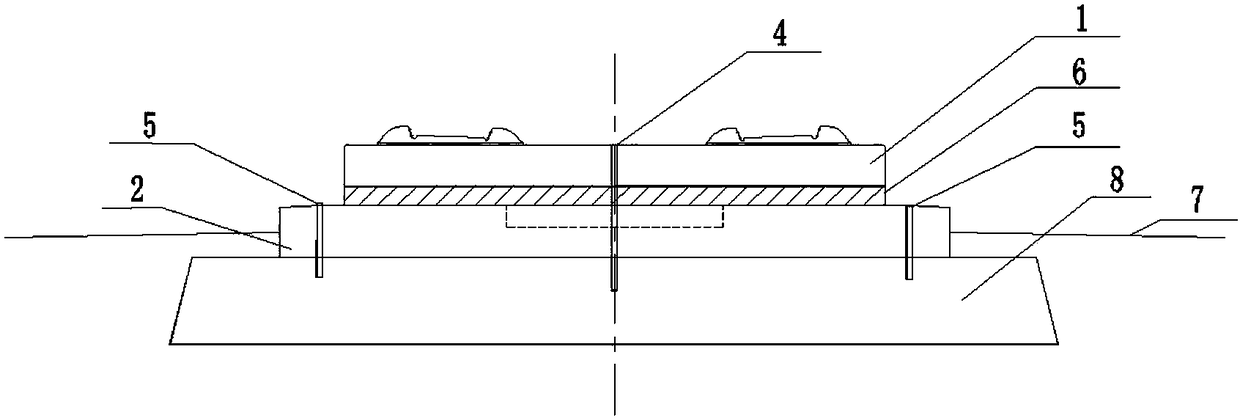

[0029] Such as Figure 1~3 , the present embodiment needs to open the glue injection hole 3 on the base plate 2, the glue injection hole 3 of this embodiment penetrates the base plate 2 and extends into the graded crushed stone layer 8 directly below the base plate 2, in order to ensure the high injection rate The expansion force generated by the polymer can stably act on the base plate 2 and the track plate 1 , and the lower end of the glue injection hole 3 in this embodiment is located directly below the base plate 2 and the track plate 1 . The diameter of the injection hole 3 is 20-30 mm, and the depth is 500-800 mm.

[0030] Each base plate 2 is provided with 1 to 4 groups of glue injection holes 3, and two adjacent groups of glue injection holes 3 are arranged at intervals along the extending direction of the track. The distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com