Control system and method for concrete machine

A concrete machinery and control system technology, applied in the direction of mechanical equipment, fluid pressure actuation system components, building materials processing, etc., can solve the problems of high fuel consumption, unfavorable energy saving, slow action, etc., to reduce the driving speed, reduce energy consumption, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

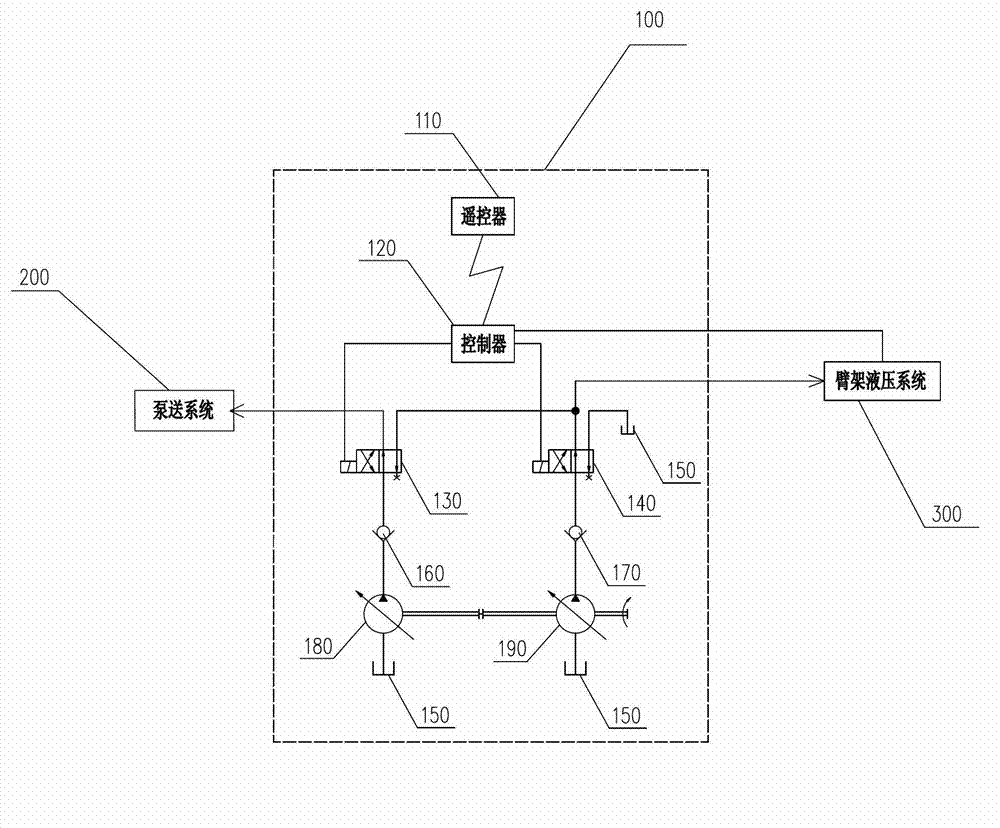

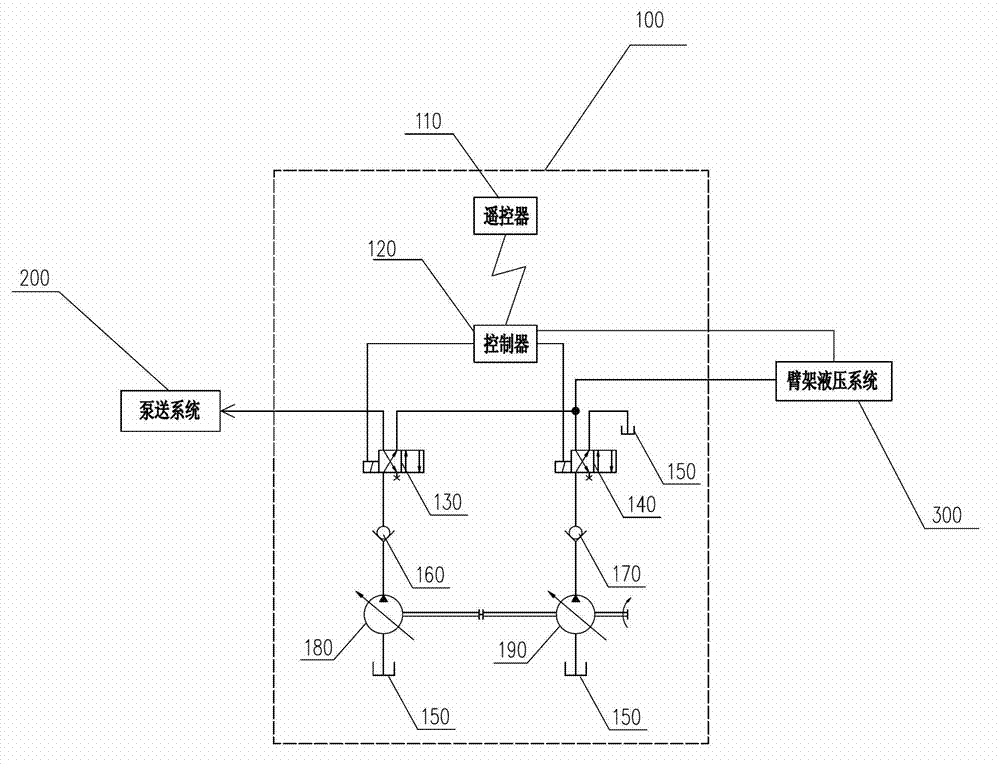

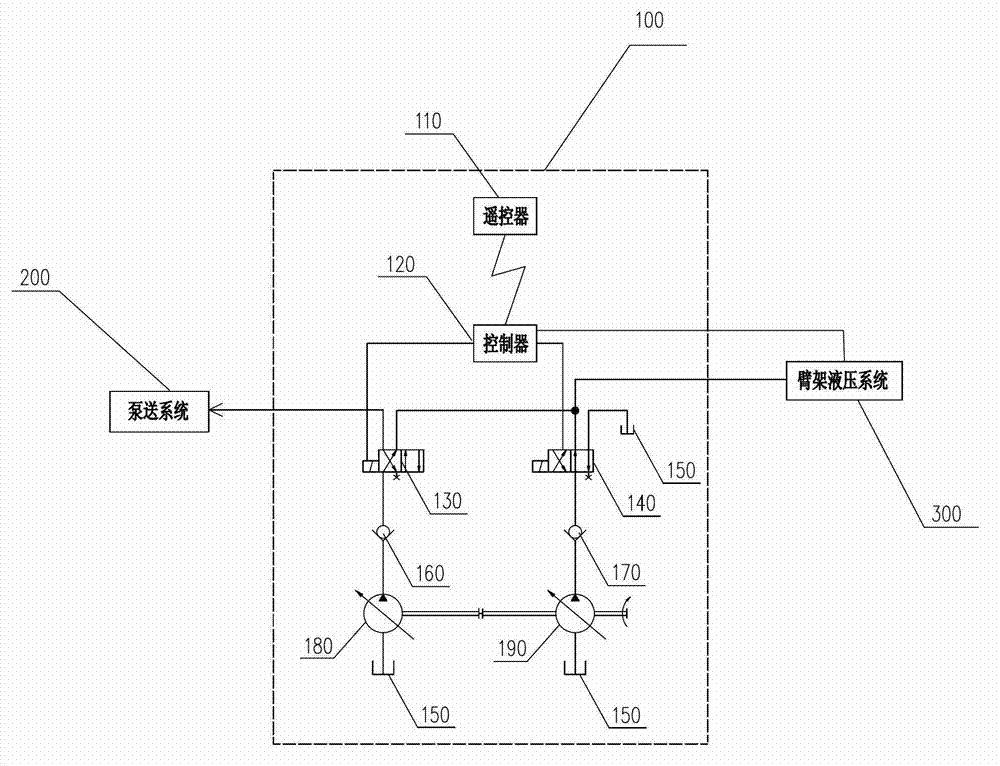

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0040] The key point of this application is: to switch the oil supply from the main oil pump to the pumping system or the hydraulic system of the boom by controlling the reversing valve. Or provide hydraulic power to the boom hydraulic system at the same time as the boom pump. By using the characteristics of the large displacement of the main oil pump, the driving speed of the driving device can be greatly reduced to achieve energy saving; The relationship between the speed can meet the demand of any flow in the hydraulic system of the boom, and realize oil supply on demand.

[0041] figure 1 It is a schematic diagram of the hydraulic oil flow of the control system when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com