Dual-safety exhaust valve

An exhaust valve, double insurance technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as safety hazards, exhaust hole blockage, medium leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

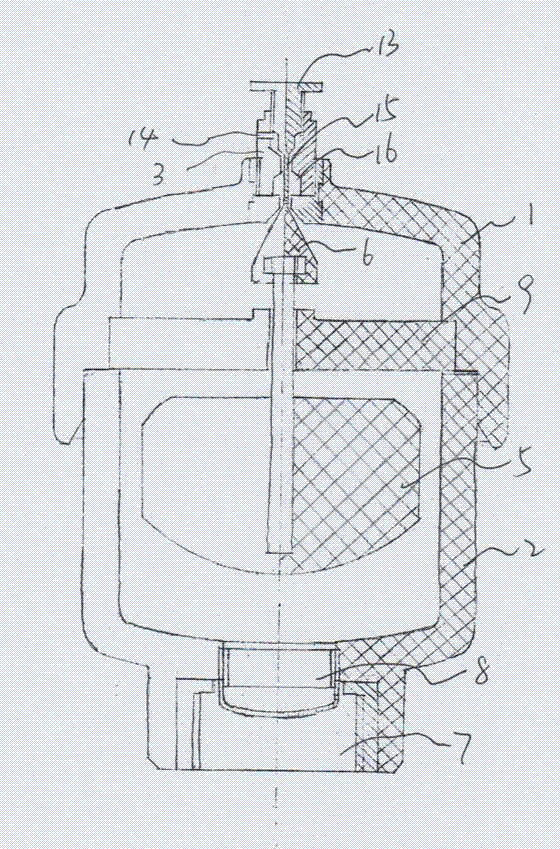

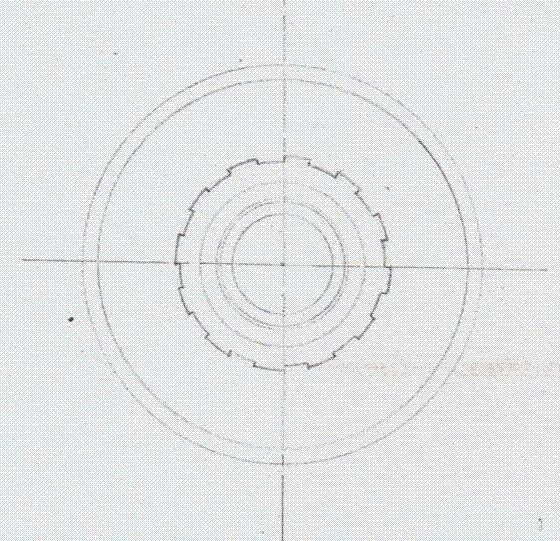

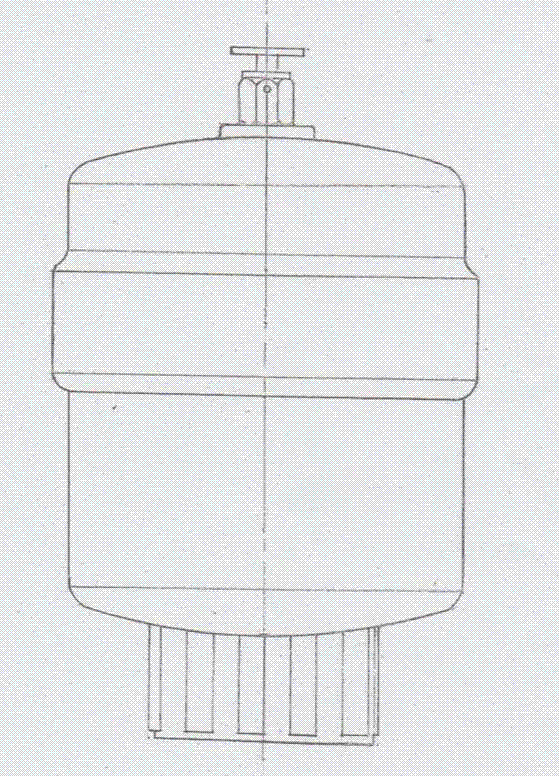

[0011] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a double safety exhaust valve, including a valve body composed of an upper valve body 1 and a lower valve body 2 that are interlocked with each other, and the upper valve body 1 and the lower valve body 2 are connected by welding In an integrated structure, a bracket 9 is provided at the junction of the upper valve body 1 and the inner cavity of the lower valve body 2, a ring is provided at the center of the bracket 9, and a side air hole 14 is provided at the upper end of the upper valve body 1. exhaust nozzle 3, the upper end of the exhaust nozzle 3 is threadedly connected with an exhaust bolt 13, the bottom end of the exhaust bolt 13 is provided with a thimble 15, the diameter of the thimble 15 is smaller than the diameter of the total exhaust hole 16, and the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com