Fixing device and detection system

A technology for fixing devices and fixing structures, which is applied to lighting devices, lighting auxiliary devices, components of lighting devices, etc., can solve the problems of labor-consuming, time and cost, high product cost, waste of resources, etc., and shorten the work cycle. , avoid long development cycle, save product cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

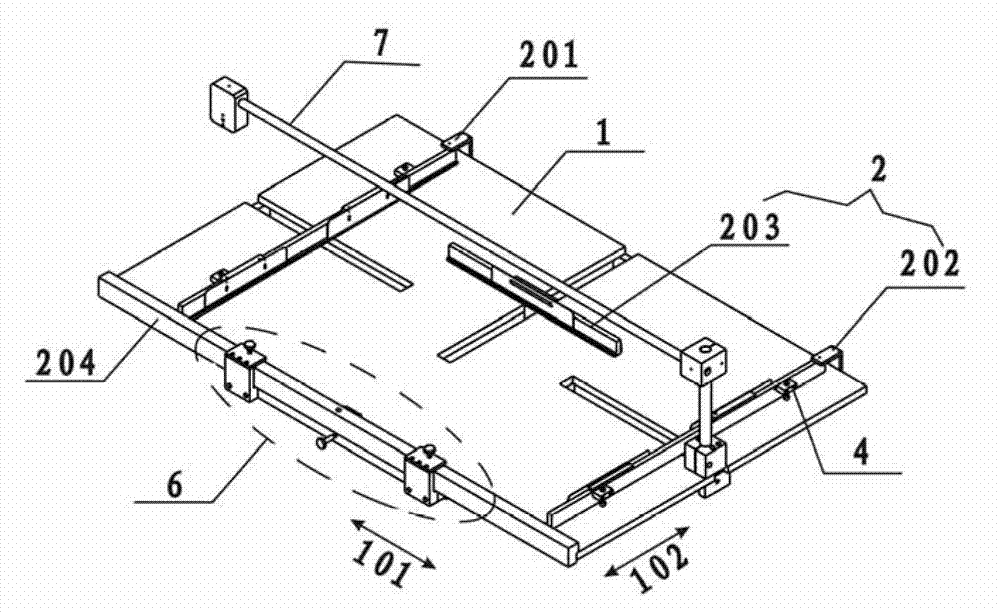

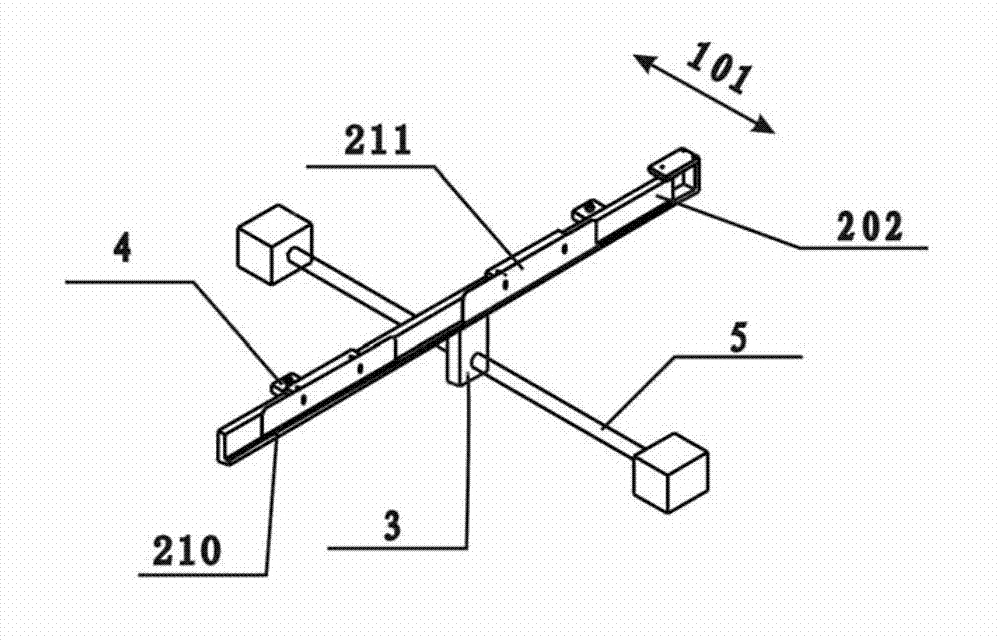

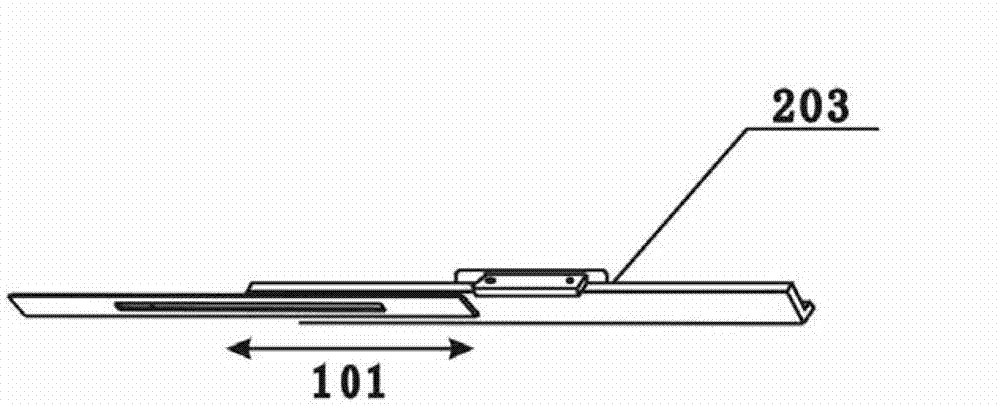

[0034] The embodiment of the present invention provides a fixing device, such as figure 1 , figure 2 As shown, it includes: a support platform 1; at least two position-limiting side walls 2, arranged on the support platform 1, for limiting the position of the edge of the object carried by the support platform, wherein at least one position-limiting side wall It is a movable limit side wall; the sliding part 3 is connected with the movable limit side wall and is used to move along the vertical direction of the movable limit side wall; the fixed part 4 is arranged on the movable limit side wall The limit side wall or the sliding part is used to fix the movable limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com