Process for digesting bonded steel of steelmaking casting slag ladle

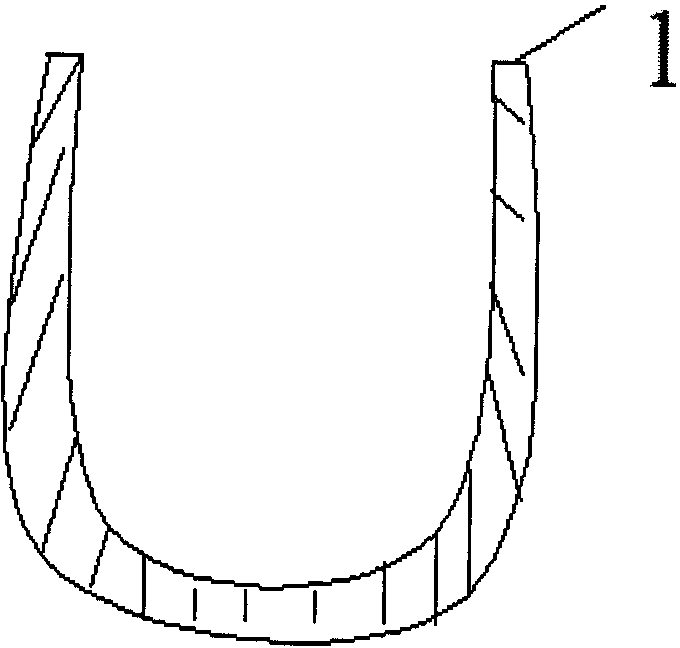

A slag pot and process technology, which is applied in the treatment field of casting residual slag sticking pot to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

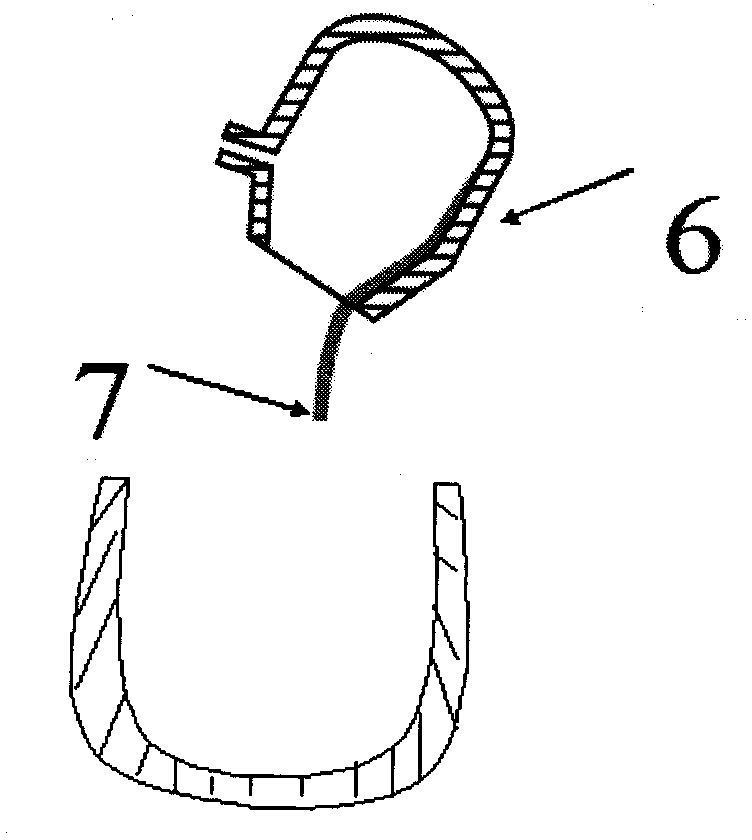

[0024] 1) Equipment conditions: 3 converters with 120 tons top and bottom auxiliary blowing, 3 LF refining furnaces, 1 set of RH vacuum refining furnace, need 21 15m 3 However, there are only 12 slag tanks that are actually equipped with turnover, and the turnover of slag tanks is seriously insufficient.

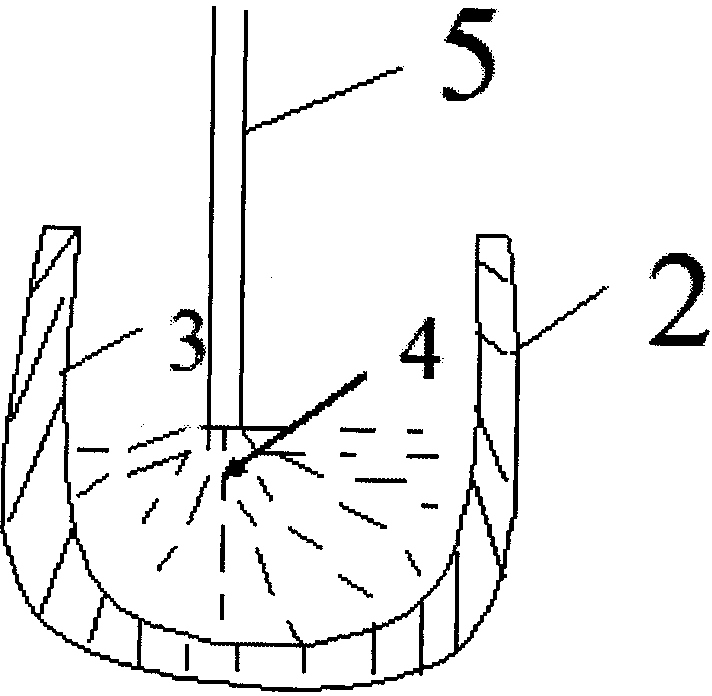

[0025] 2) For the slag tank of the converter, use a gas atomization spraying device to spray the anti-sticking slag agent. The dosage is 0.08kg per ton of slag, spray for 7 minutes, and have a thickness of 10mm.

[0026] 3) For the slag tank filled with liquid steel slag, it is treated by hot pouring or upper drum slag treatment; the drum slag treatment is mechanized automatic control operation equipment to complete the tipping of the slag tank, and pour the liquid steel slag in the tank into the drum of the drum slag equipment body Inside (similar to the principle of a drum washing machine), it automatically completes the process of pumping and crushing liquid steel slag; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com