Detonator reel

A detonator wire and axis technology, which is applied in the field of spools for placing detonators, can solve the problems of packages and packages being detonated, harmed, destroyed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

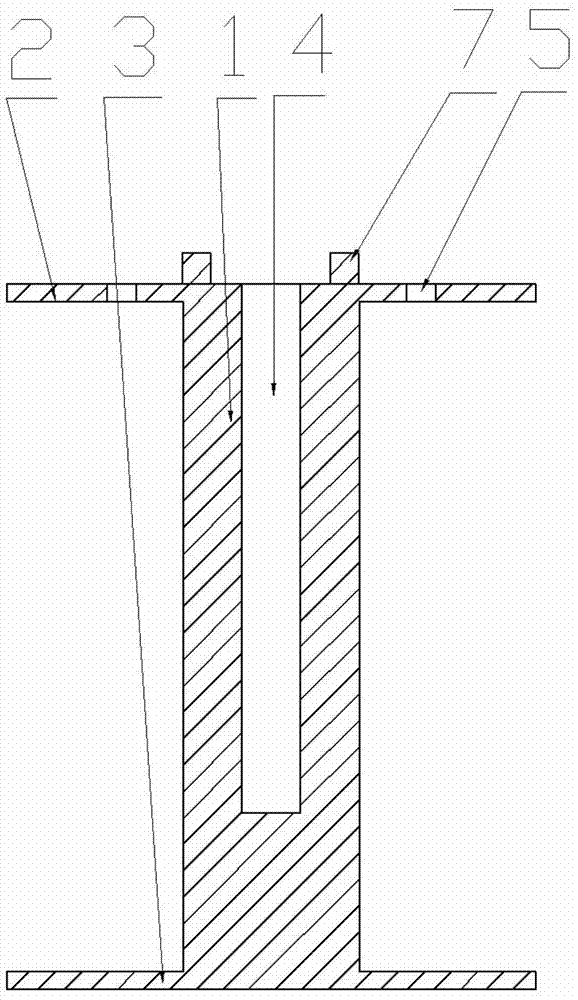

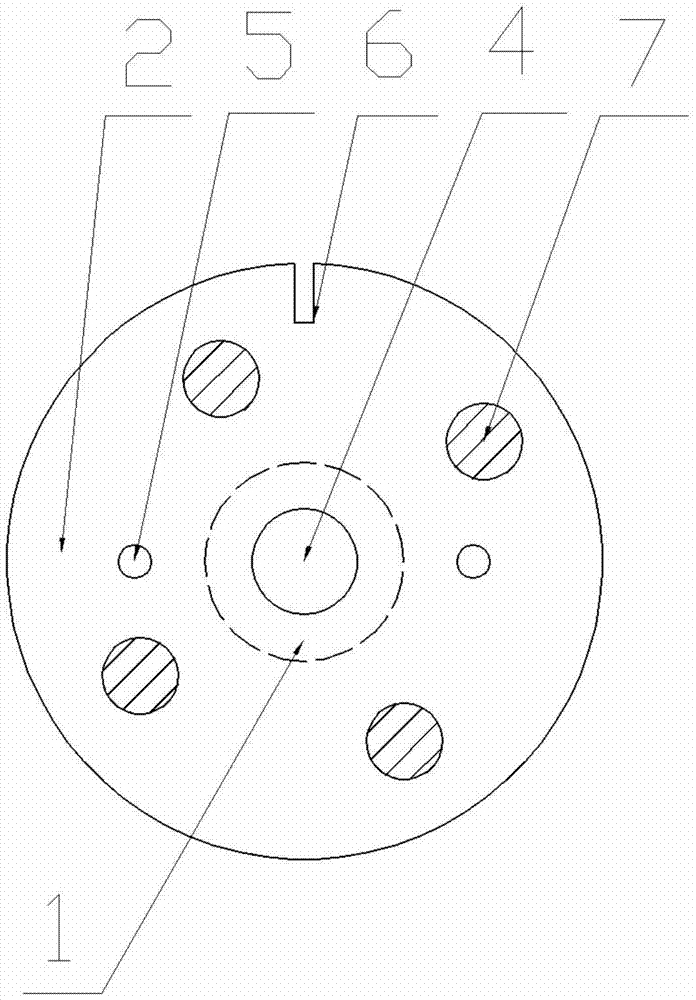

[0011] Detonator spools, such as figure 1 , figure 2 As shown, it includes a winding shaft 1, an upper baffle plate 2 arranged at the upper end of the winding shaft 1, and a lower baffle plate 3 arranged at the lower end of the winding shaft 1; the axis position of the winding shaft 1 is provided with a placement hole 4 with an upper opening; The length of the hole 4 is 4 to 5 mm less than the length of the detonator; the diameter of the placement hole 4 is 1 to 3 mm larger than the diameter of the detonator; the surface of the upper baffle 2 is provided with two lead holes 5, and can also be set to one or more according to the situation. A wire hole 5, the diameter of the wire hole 5 is slightly larger than the wire diameter; the edge of the upper baffle plate 2 is provided with a wire clamping groove 6, and a plurality of wire clamping grooves 6 can also be set according to the situation. Four studs 7 are arranged on the upper surface of the upper baffle plate 2, and two o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap