Method and device for measuring mechanical property of cement-based material

A technology of cement-based materials and measuring devices, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of inability to monitor the development and change of elastic parameters, inaccuracy, and large Poisson fluctuation range, etc., and achieves easy and convenient measurement methods. Simple device structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

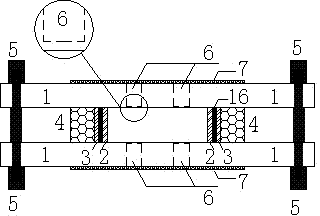

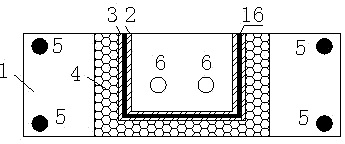

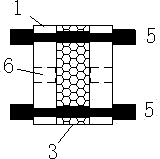

[0035] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0036] The idea of the present invention is to pour the mixed cement-based material into a cuboid test mold with an upper opening to form a cuboid to be tested. The width of the test mold, that is, the minimum distance between two parallel material plates, depends on the type of cement-based material. For cement paste and mortar, the minimum distance is preferably 100mm; if it is concrete, the minimum distance is 120mm; then the propagation speed of ultrasonic longitudinal wave and transverse wave in the test piece is continuously monitored throughout the research age; and according to the cement-based material The relationship between the dynamic elastic modulus, Poisson's ratio and the propagation speed of ultrasonic longitudinal wave and transverse wave is calculated synchronously to obtain the change of the dynamic elastic modulus and Poisson's rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com