Miniaturized continuous zoom camera lens with large field of view

A camera lens, zoom technology, applied in installation, optics, instruments, etc., can solve the problems of high-precision camera mismatch, limited observation ability, low resolution, etc., to achieve no image plane jump, good coaxiality, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

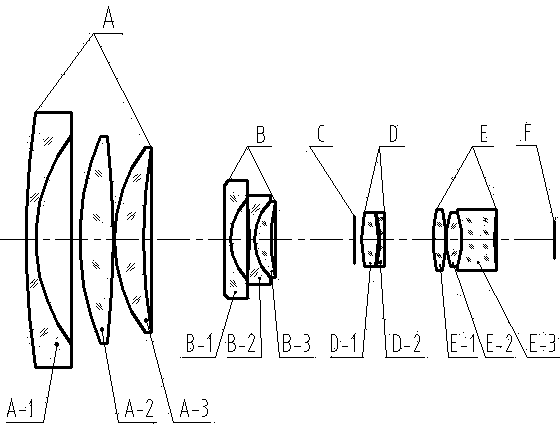

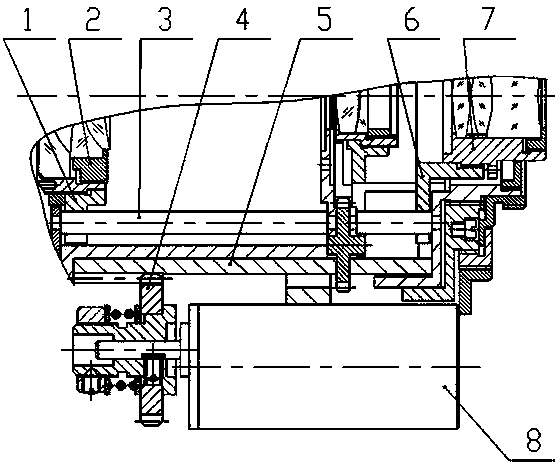

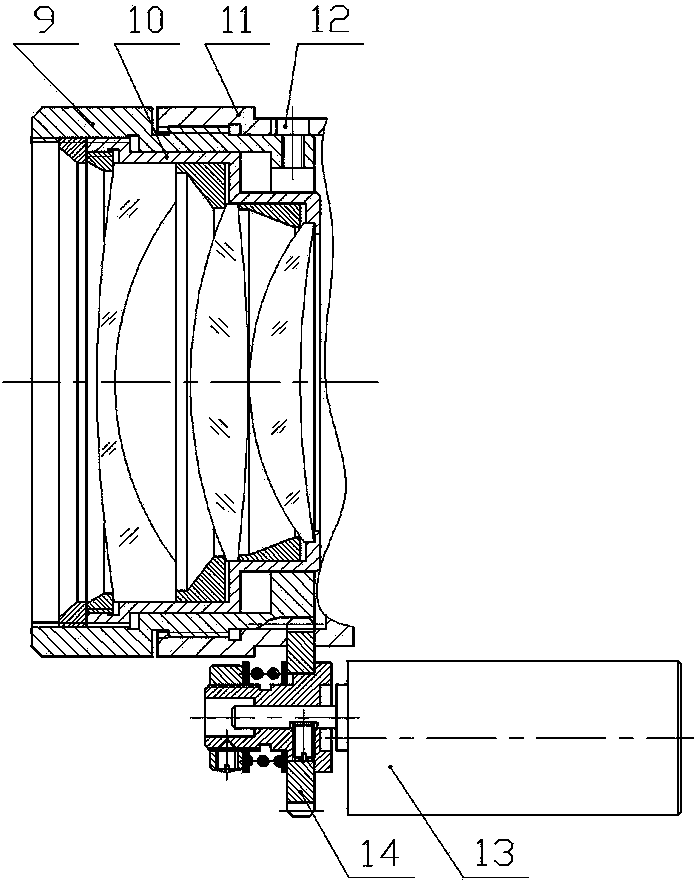

[0015] Such as figure 1 As shown, a large field of view miniaturized continuous zoom camera lens, the optical structure of the lens is respectively provided with a front fixed group A with a positive focal power and a negative focal power along the incident direction of the light from left to right. zoom group B, variable diaphragm assembly C, rear fixed group D with positive refractive power, and compensation group E with positive refractive power. The front fixed group A is sequentially provided with negative crescent lens A-1, Biconvex lens A-2 and positive crescent lens A-3, said variable power group B is provided with biconcave lens B-1 and the first cemented group closely connected by biconcave lens B-2 and positive crescent lens B-3, said The rear fixed group D is sequentially provided with biconvex lens D-1 and negative crescent lens D-2, and the compensation group E is sequentially provided with biconvex lens E-1 and a second lens closely connected by biconvex lens E-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap