Rolling stand with roll bearing

A roll and support technology, which is applied in the field of roll supports with roll support devices, can solve the problems of high cost and necessary replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

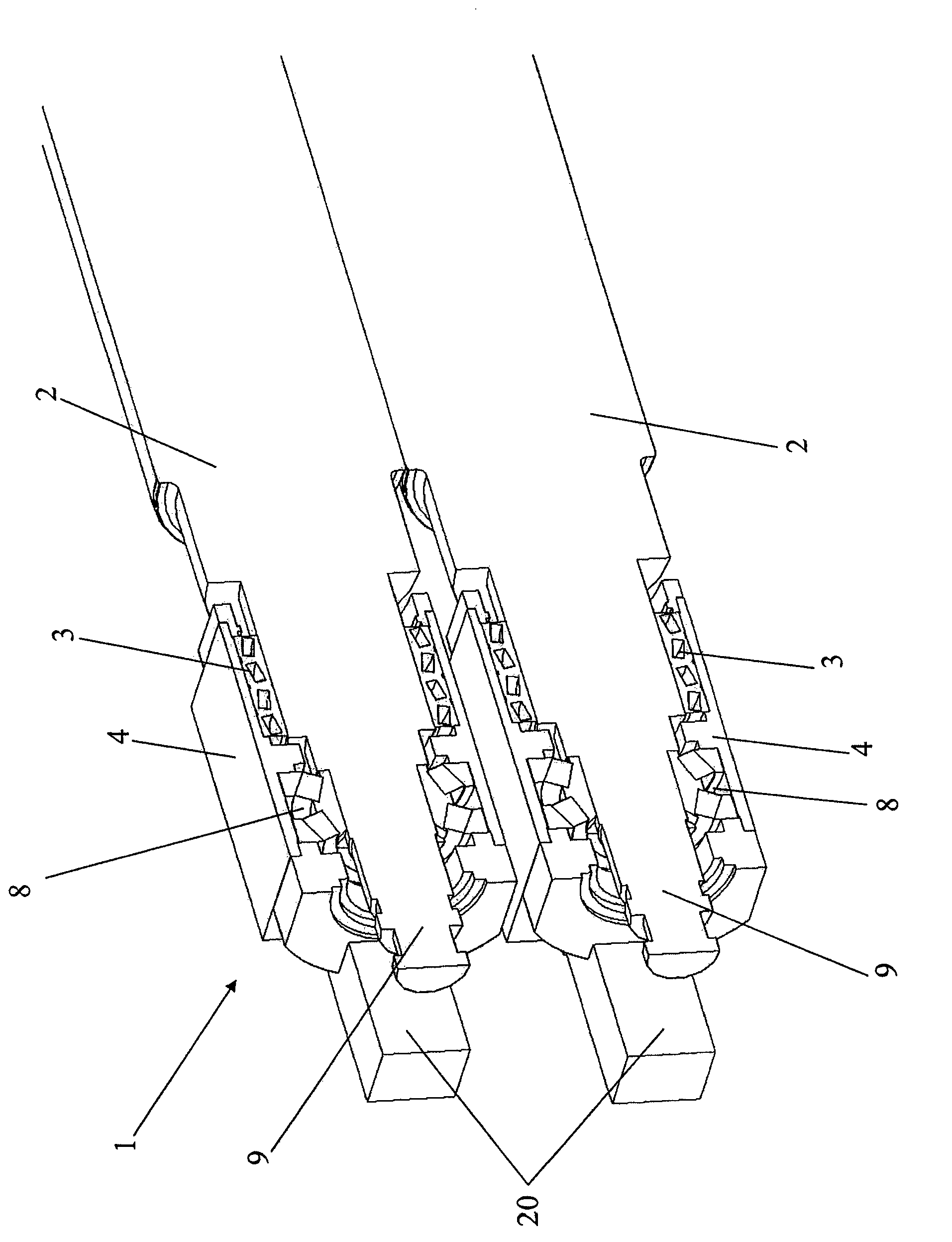

[0023] figure 1 The middle table shows a conventional rolling installation 1 with an axial displacement device according to the prior art. The work roll 2 is embodied in one piece. They are supported in the one-piece work roll insert 4 via a radial bearing 3 and an axial bearing 8 arranged on the roll head 9 . The bearing cap 20 is screwed onto the roll insert 4 . The axial force is transmitted to the work roll 2 via the axial bearing 8 .

[0024] In order to transform the traditional rolling equipment without axial movement into figure 1 Rolling installations with axial displacement have previously had to replace at least the entire work roll and the entire roll insert.

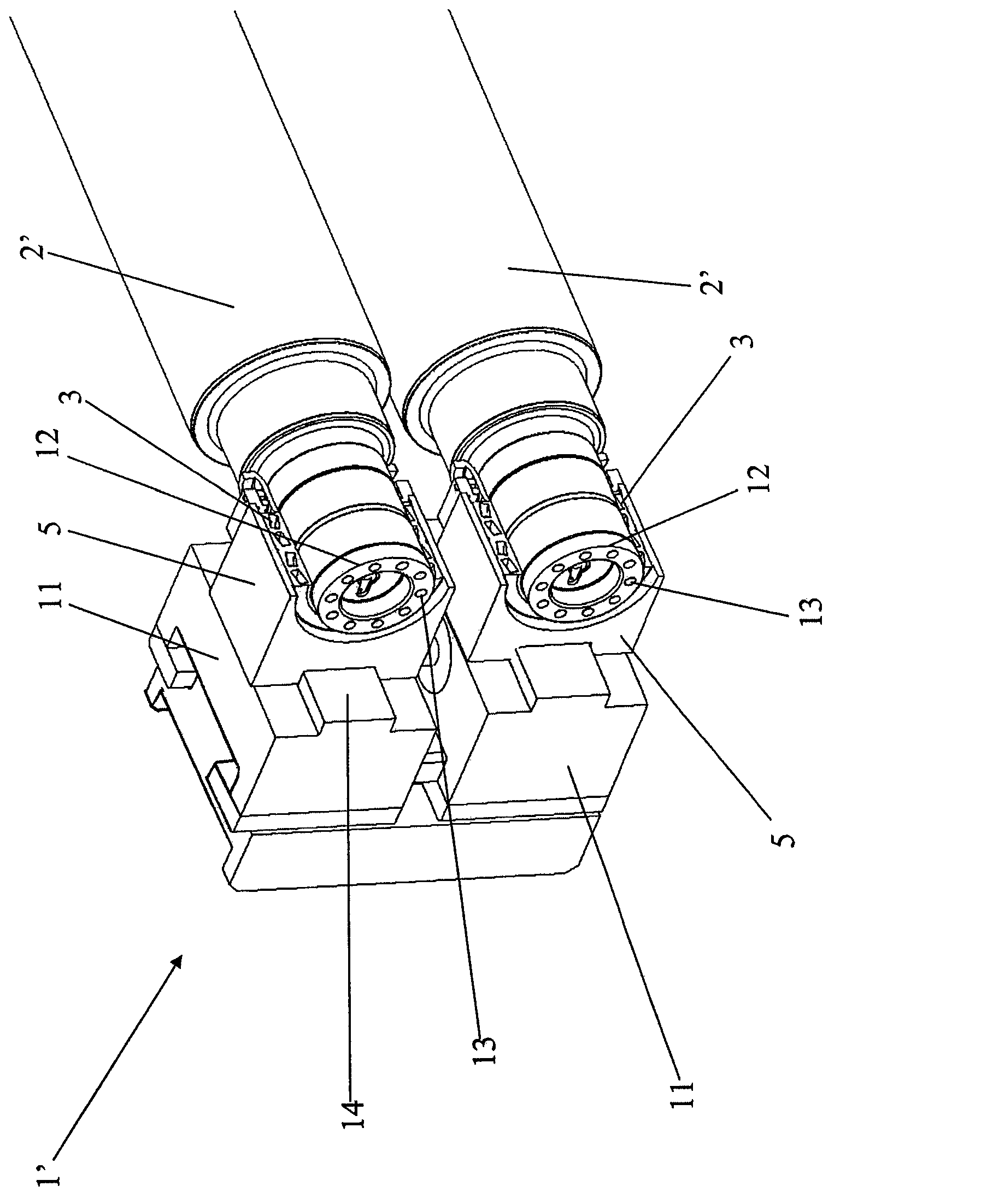

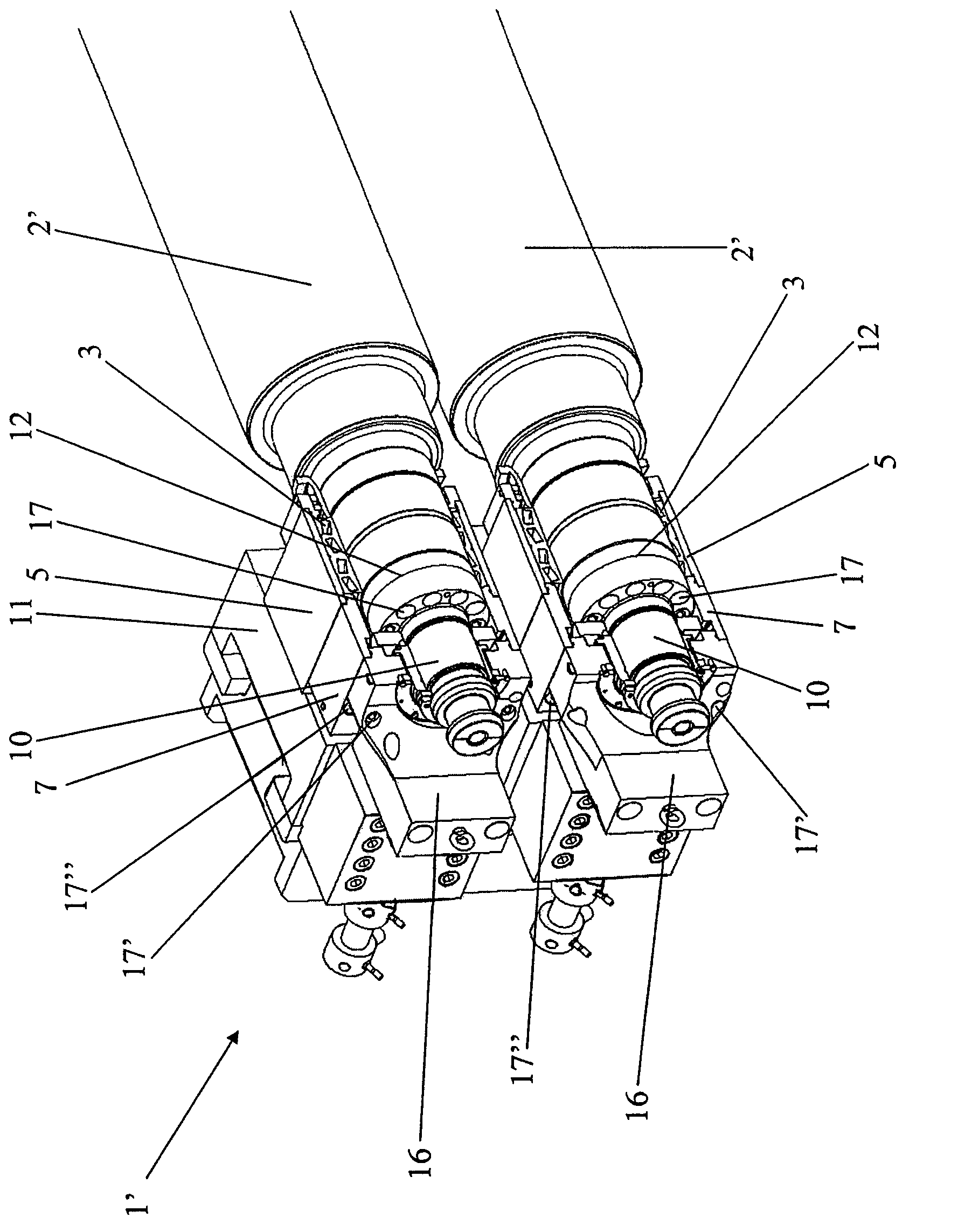

[0025] figure 2 A rolling installation 1' according to the invention is shown, wherein neither the axial locking mechanism nor the axial displacement device is shown here for better illustration.

[0026] The work rolls 2' are supported with radial bearings 3 in roll inserts 5 for axial support, respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com