Omni wheel assembly and Omni vehicle

An omnidirectional wheel and vehicle technology, applied in the directions of wheels, vehicle components, elastic suspension, etc., can solve the problems of complicated and expensive transmission, and achieve the effect of optimizing operation and simplifying use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

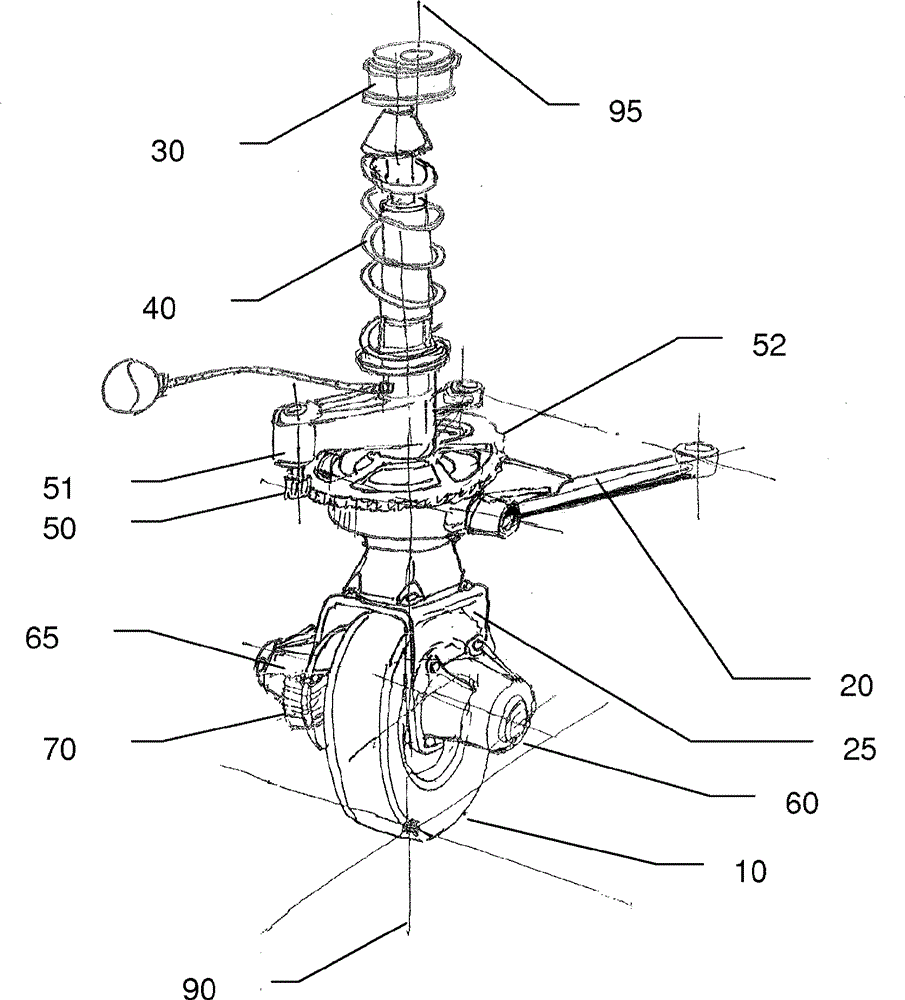

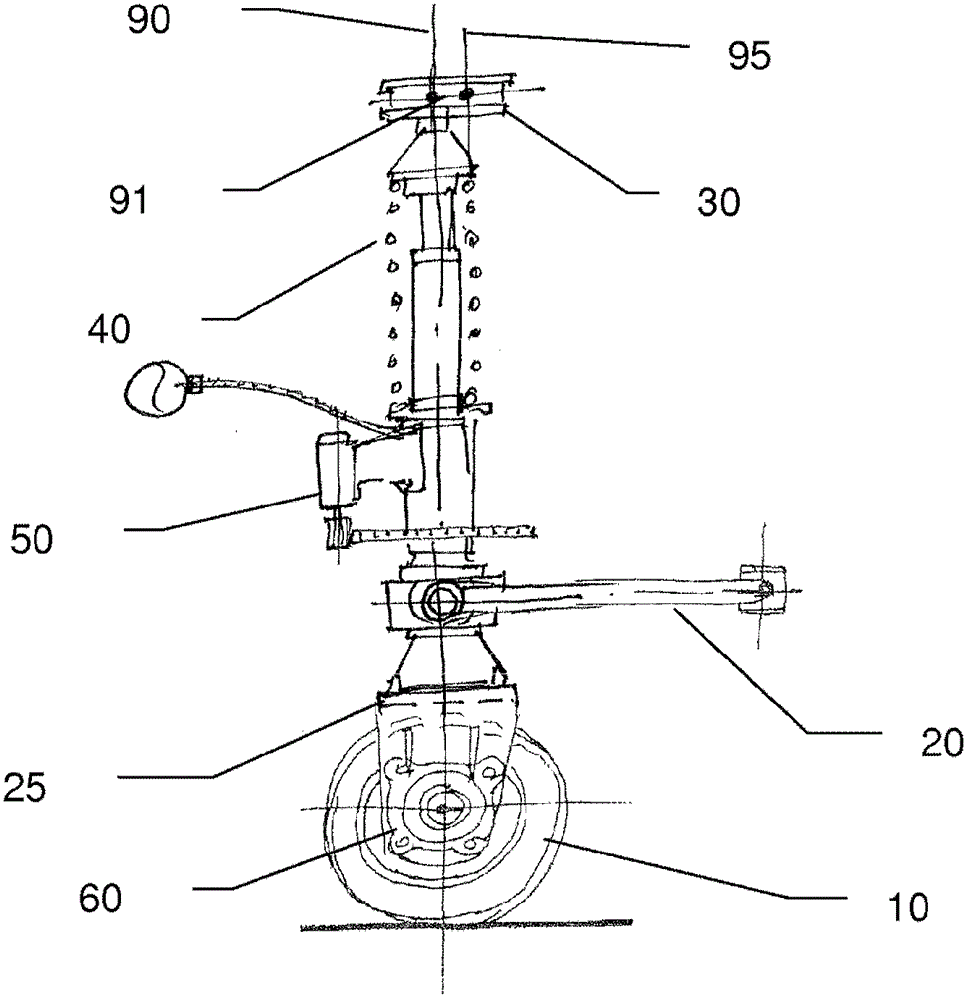

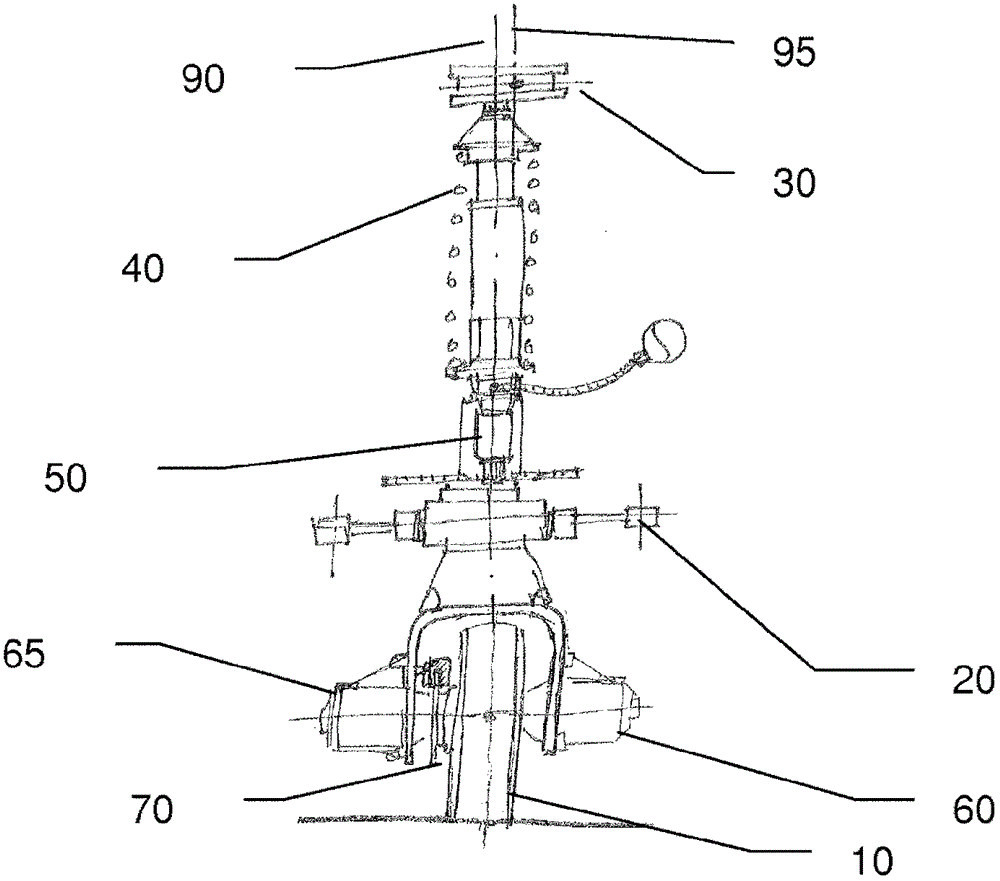

[0029] figure 1 The omnidirectional wheel assembly shown in includes a wheel 10 mounted on a fork 25 and capable of rotating 360° about a pivot axis 90 . This capability allows a vehicle equipped with this omnidirectional wheel assembly to steer in all directions. Users can easily steer vehicles to park in lots with narrow access or to move in traffic jam situations. In this object, the assembly is equipped with a steering mechanism 50 comprising a steering motor 51 engaged with a circular steering rack. In addition, the assembly includes two electric motors 60, 65 for applying moving force to the vehicle, although one motor may be sufficient, and braking equipment 70 for stopping the vehicle if required. The suspension assembly 40 includes suspension springs connected to suspension dampers. The assembly is connected to the vehicle via a lower suspension arm 20 and an upper connection joint 30 . These two elements define the geometry of the wheel assembly in the vehicle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com