Glass composition for producing high strength and high modulus fibers

A glass composition, the technology of the composition, applied in the direction of fabric, final product manufacturing, textile, etc., can solve problems such as harming refractory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

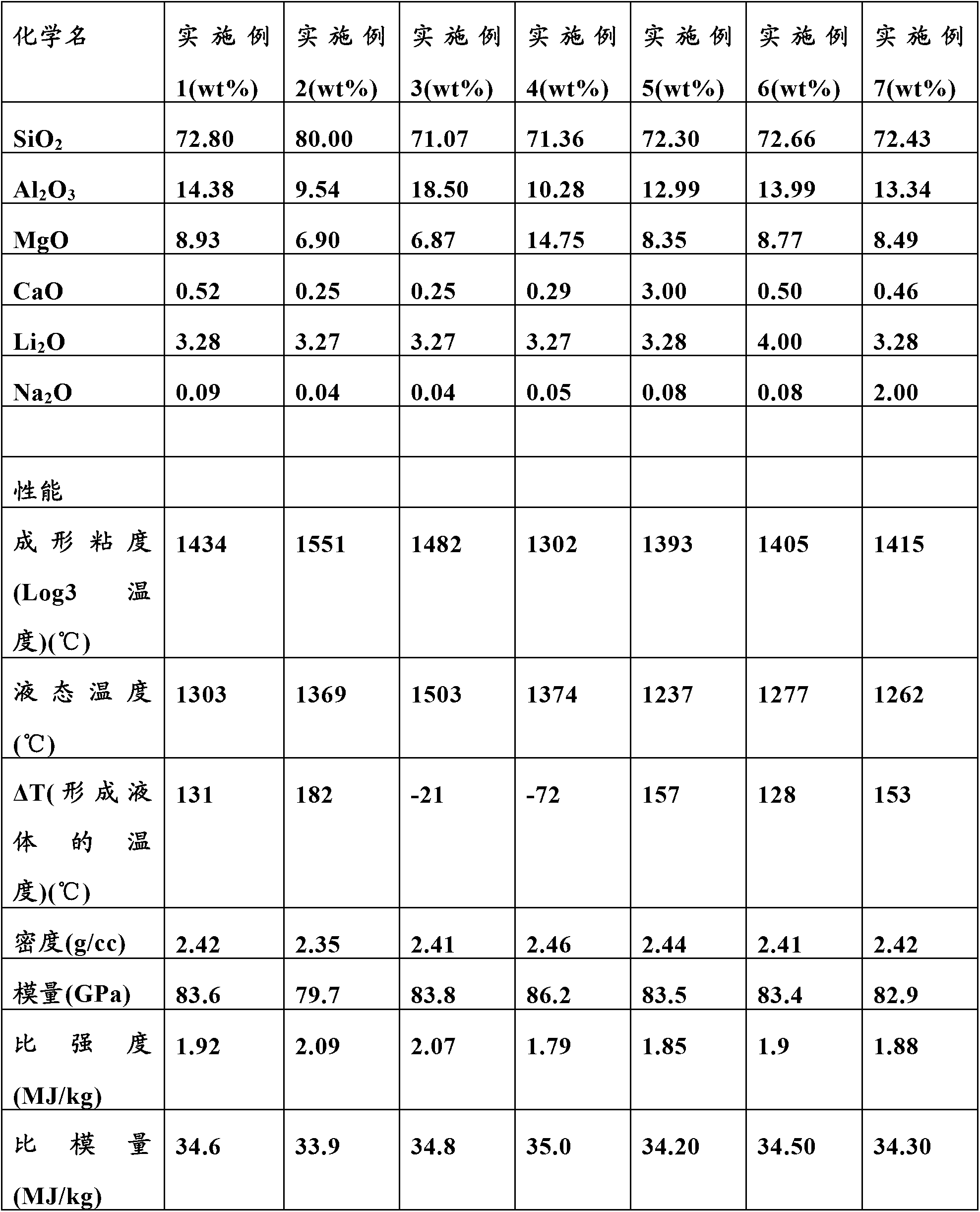

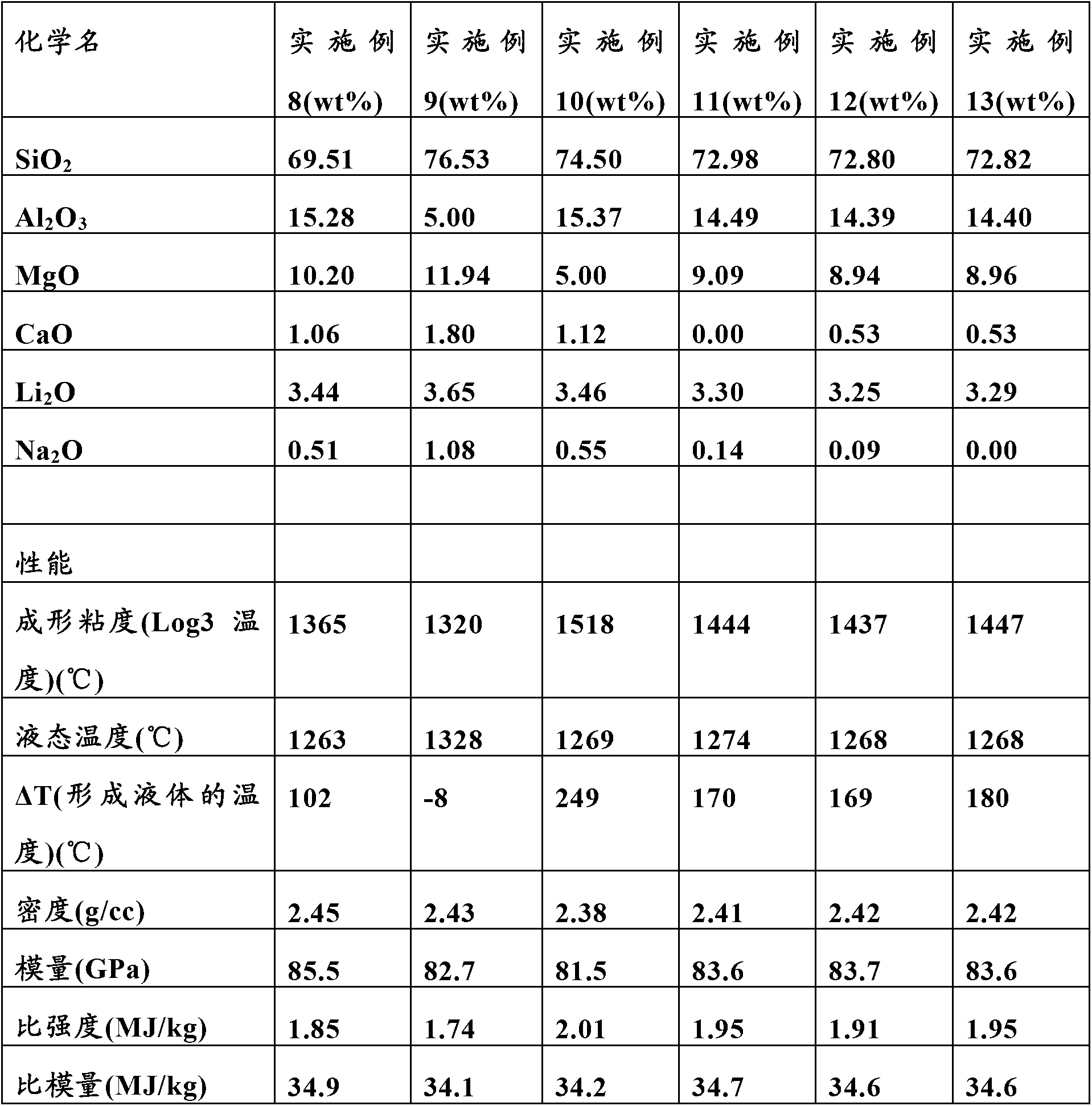

[0054] Example 1: High Performance Glass Composition

[0055] Glass compositions of the present invention were made by mixing reagent grade chemicals in amounts in suitable proportions to achieve final glass compositions having the oxide weight percents listed in Table 4. The raw materials were melted at a temperature of 1650° C. for 3 hours in a platinum crucible in an electrically heated furnace. The formed viscosity (ie, the temperature corresponding to a viscosity of about 1000 poise) was measured using the rotating cylinder method (ASTM C965-96 (2007)). In a platinum-alloy vessel, the liquidus temperature is measured by exposing the glass to a temperature gradient for 16 hours (ASTM C829-81 (2005)). Density was measured on unannealed bulk glass by the Archimedes method (ASTM C693-93 (2008)). The moduli reported in the table below were measured on 5 individual glass fibers according to the procedure outlined in the report "Glass Fiber and Measuring Facilities at the U.S....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com