Once thermal molding device of optical glass

An optical glass and thermoforming technology, which is applied in the field of optical glass forming, can solve the problems of high waste glass material, high product cost, and long production cycle of optical components, etc., and achieve low molding viscosity, consistent weight, and short material properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

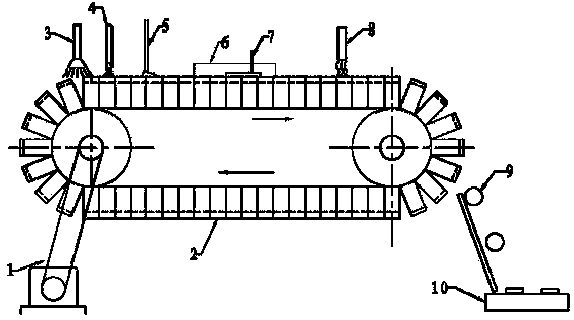

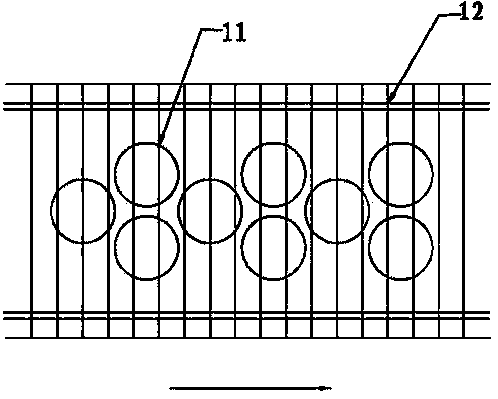

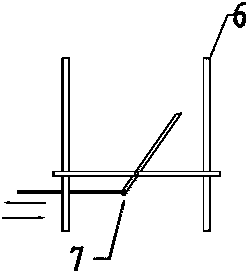

[0014] Such as Figure 1 to Figure 4 shown. The optical glass primary thermoforming device of the present invention is composed of a bottom mold 2, a bottom mold transmission device 1, a side baffle 6, scrapers 7, 13, a burner 3, a spray gun 4, a leakage pipe 5, a cooling pipe 8 and a storage device 10. . Wherein, bottom mold 2, side baffle 6, scraper 7, 13 select superhard heat-resistant alloy to make for use. The bottom mold 2 is formed by a plurality of narrow and long modules closely arranged, and the adjacent modules are hingedly connected, and the end to end is connected in a ring-shaped crawler pattern, and the number of connected modules is determined by the glass grade to be produced. A sinker is formed on the bottom mold 2 according to the appearance shape of the prefabricated part to be formed, and a plurality of modules are closely arranged to form a complete sinker 11 . The side baffle 6 is a pair of two pieces, arranged above the both sides of the annular modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com