Manufacturing method of plate type oxygen sensor chip

A technology of oxygen sensor and manufacturing method, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of easy deformation of sintering, poor compactness, poor performance, etc., achieve smooth and smooth substrate quality, solve lamination and sealing, and improve The effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

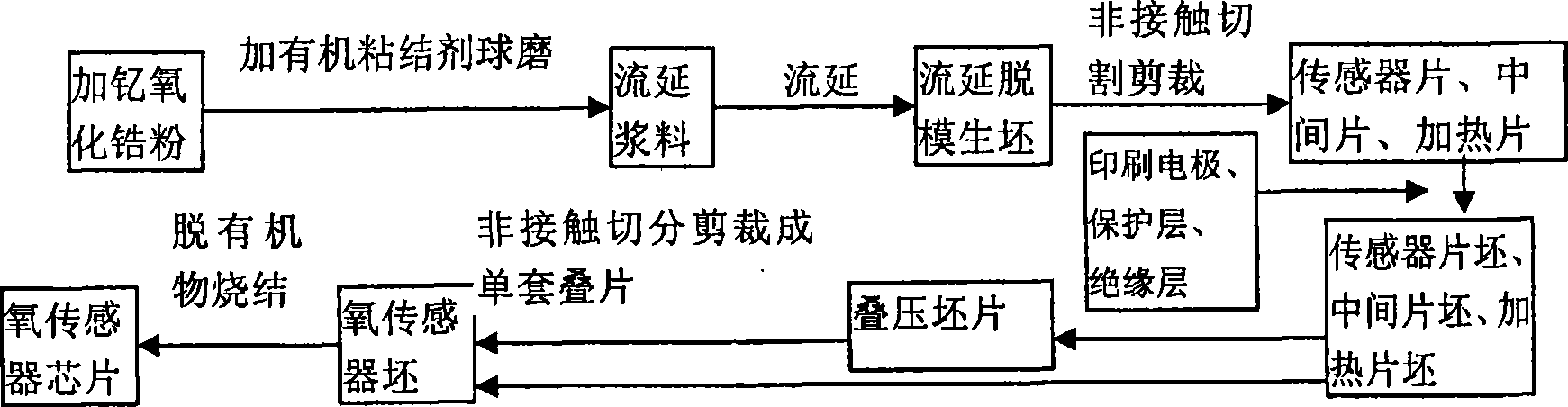

Method used

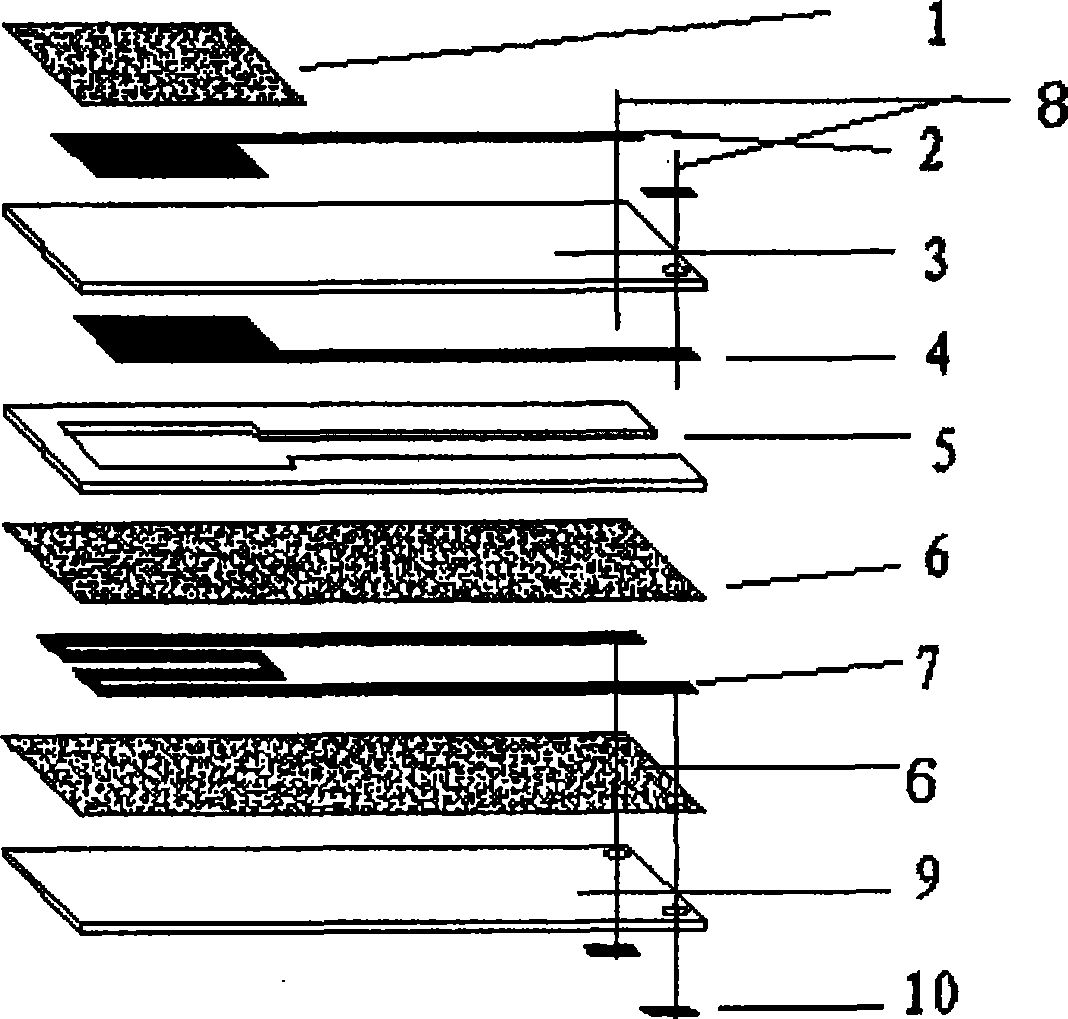

Image

Examples

Embodiment 1

[0029] 1. Prepare cast slurry: Put 200 grams of yttrium-doped zirconia powder as the base material for the sensor sheet, intermediate sheet and heating sheet into a ball mill jar, first add 120 ml of ethanol for ball milling, and then add 14 grams of polyethylene Alcohol butyral is used as a binder, continue ball milling, and when the mixture reaches a viscosity of 500-4000mPa.s, it becomes a casting slurry;

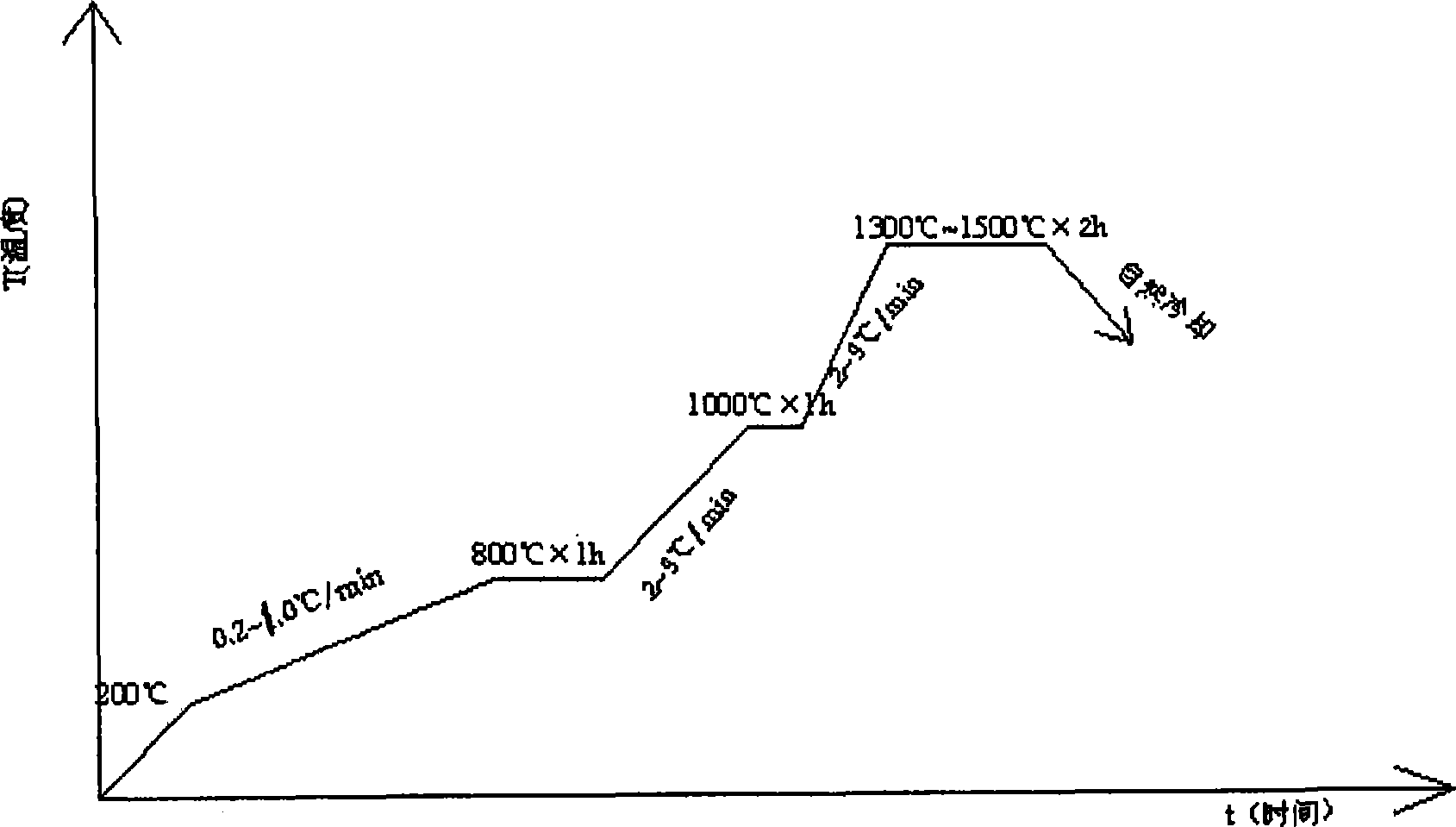

[0030] 2. Casting: The casting slurry prepared in the first step is scraped on the casting machine with a scraper on the backing belt to form a film with uniform thickness. The thickness of the casting is adjusted by the height of the scraper, the speed of the tape and the viscosity of the slurry. Control, the height of the scraper is adjusted by the micrometer placed on the scraper frame, the drying speed of the film is affected by the temperature and the organic solvent content in the film, generally it is dried at room temperature, and it can be controlled at 30°C in w...

Embodiment 2

[0037] 1. Preparation of casting slurry: Put 200 grams of yttrium-doped zirconia powder as the base material for the sensor sheet, intermediate sheet and heating sheet into a ball mill tank, first add 120 ml of xylene and 3 g of triethanolamine for dispersion Agent ball milling, then add 16 grams of polyvinyl alcohol as binding agent;

[0038] All the other steps are the same as in Example 1.

Embodiment 3

[0040] 1. Preparation of casting slurry: Put 200 grams of yttrium-doped zirconia powder as the base material for the sensor sheet, intermediate sheet and heating sheet into a ball milling tank, first add 120 ml of toluene and 3 grams of fish oil as a dispersant for ball milling , then add 10 grams of ethyl cellulose as a binder, add 5 grams of butyl benzyl phthalate and 5 grams of polyethylene glycol as plasticizers and lubricants to continue ball milling, when the mixture reaches 500 ~ 4000mPa.s Viscosity, that is cast slurry;

[0041] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com