Optical sight (variants)

An optical aiming and cube technology, applied in the field of optical sights, can solve the problems of indistinguishable, not allowing shooters to shoot, etc., and achieve the effect of precise aiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

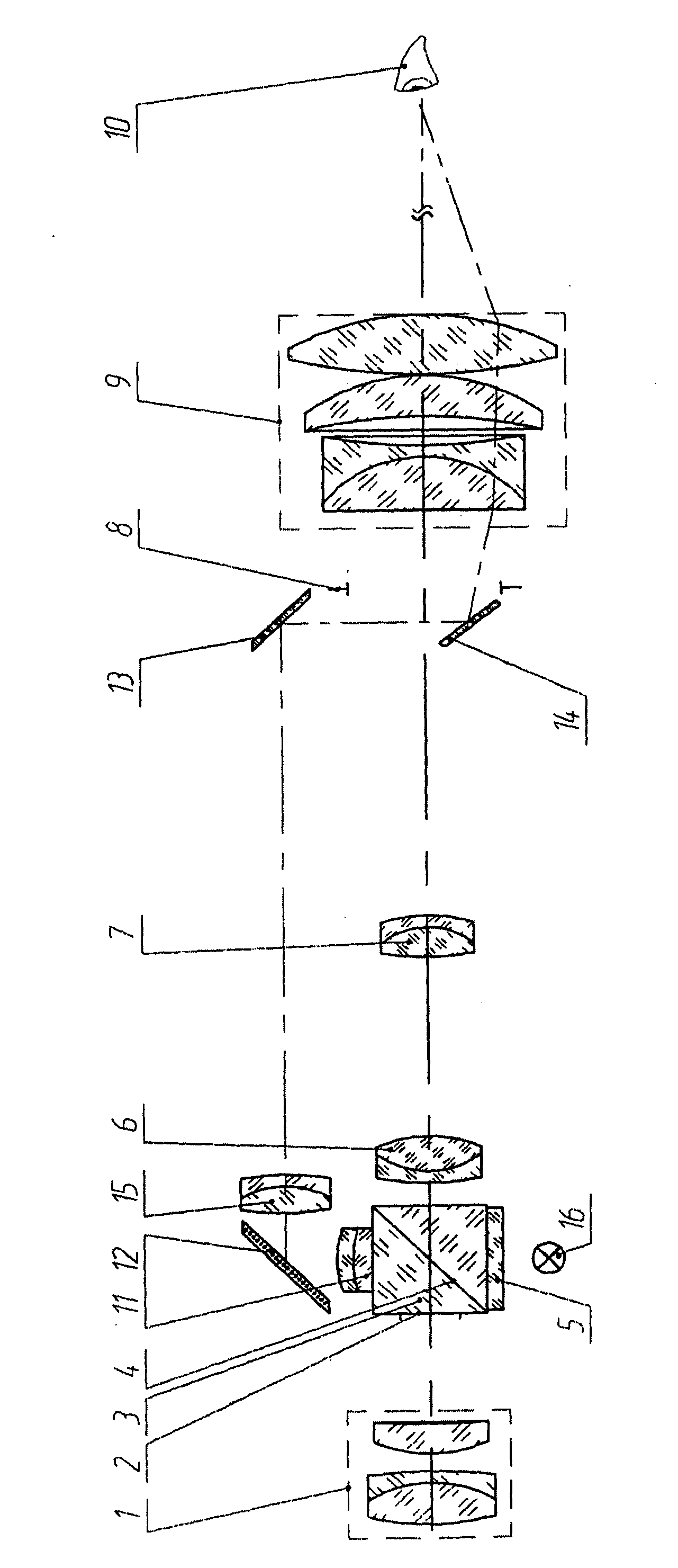

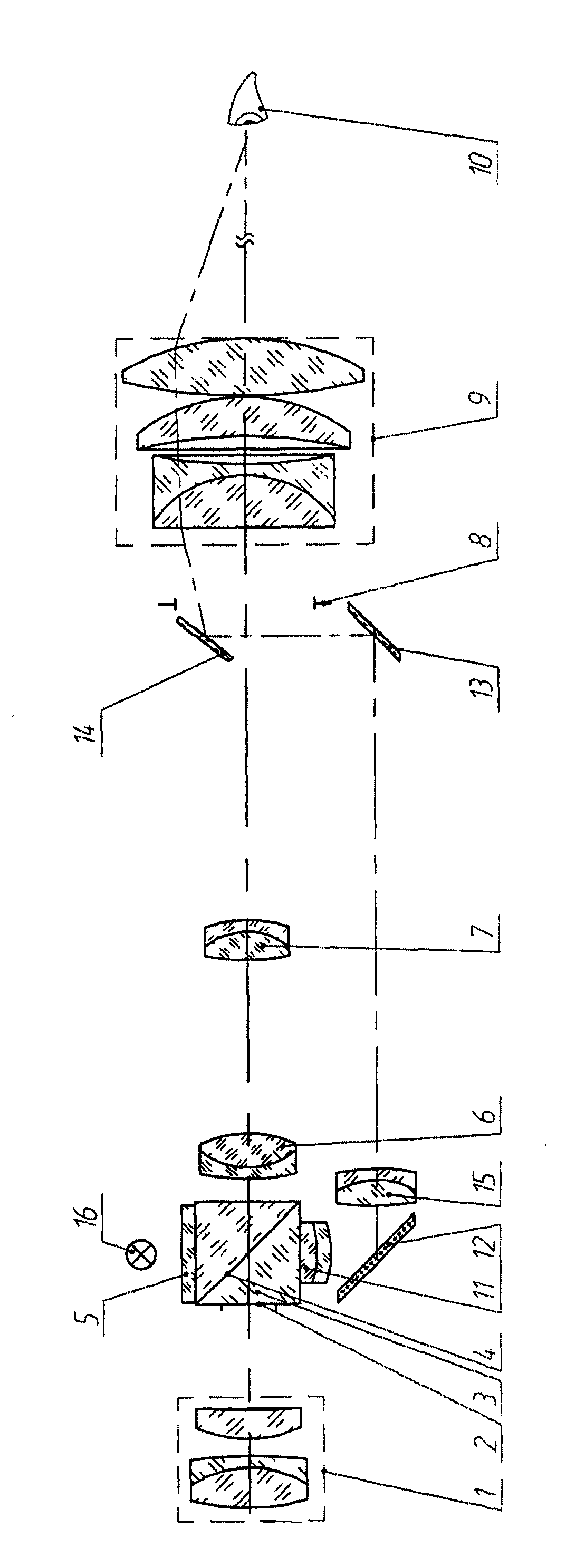

[0020] Variant 1

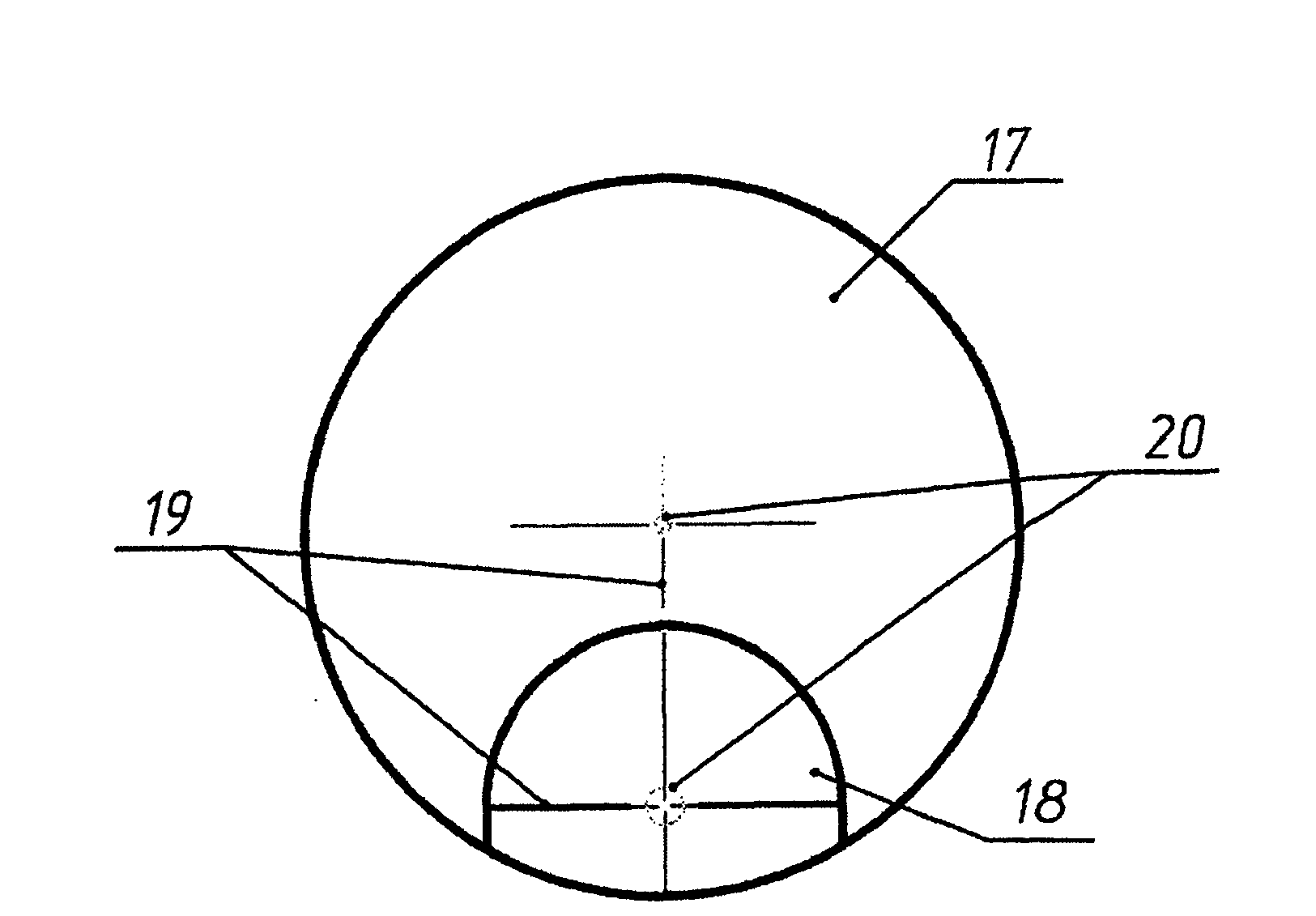

[0021] This variant of the optical sight is in the figure 1 , the figure shows sequentially on the same axis: objective lens 1; There is a beam-splitting surface 4, on the lower surface of which beam-splitting cube is placed an illuminated reticle 5 made transparent with respect to an opaque background; and a first positive part 6 of the positive imaging system ; The second positive component 7 of the positive image system; the focal plane 8 of the eyepiece 9 ; and the shooter's eye 10 . The third positive part 11 is glued on the upper plane of the cube 3; the first plane mirror 12 is arranged on the third positive part 11, parallel to the beam splitting surface 4 of the cube 3; the second plane mirror 13 is arranged perpendicular to the first plane mirror. The third plane mirror 14 is arranged obliquely to the optical axis, with its reflective surface facing the eyepiece 9, between the focal plane 8 of the eyepiece 9 and the second part 7 of the erecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com